Hydraulic pressure tube expanding device

A tube expansion device and water pressure technology, applied in heat exchange equipment, etc., can solve problems affecting the performance of refrigerators and internal threaded tubes, and achieve high airtightness, increased stability, and improved bonding rates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

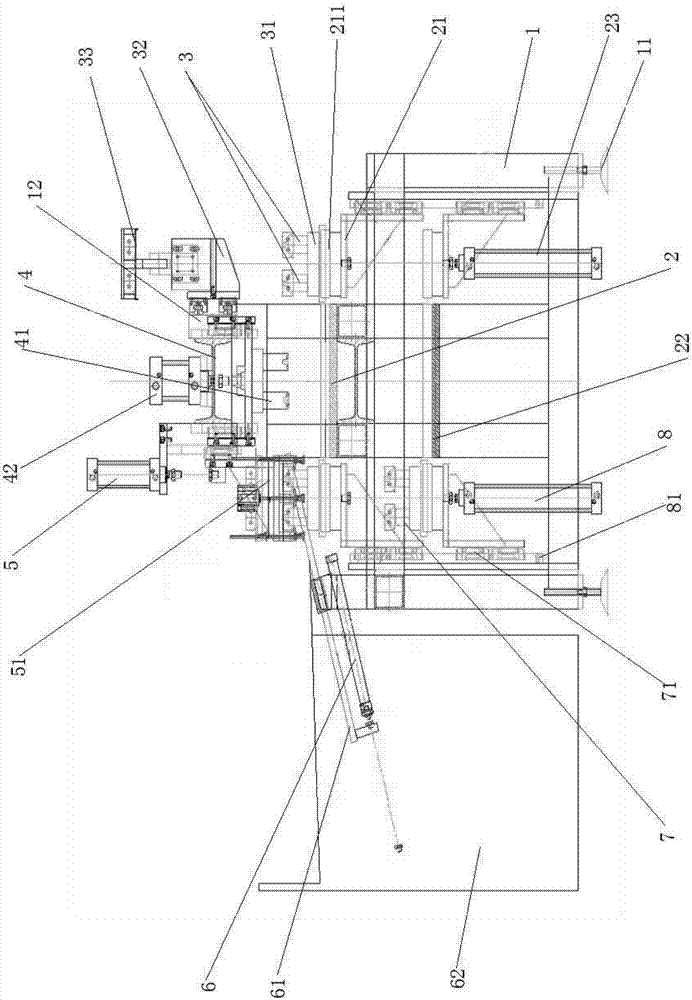

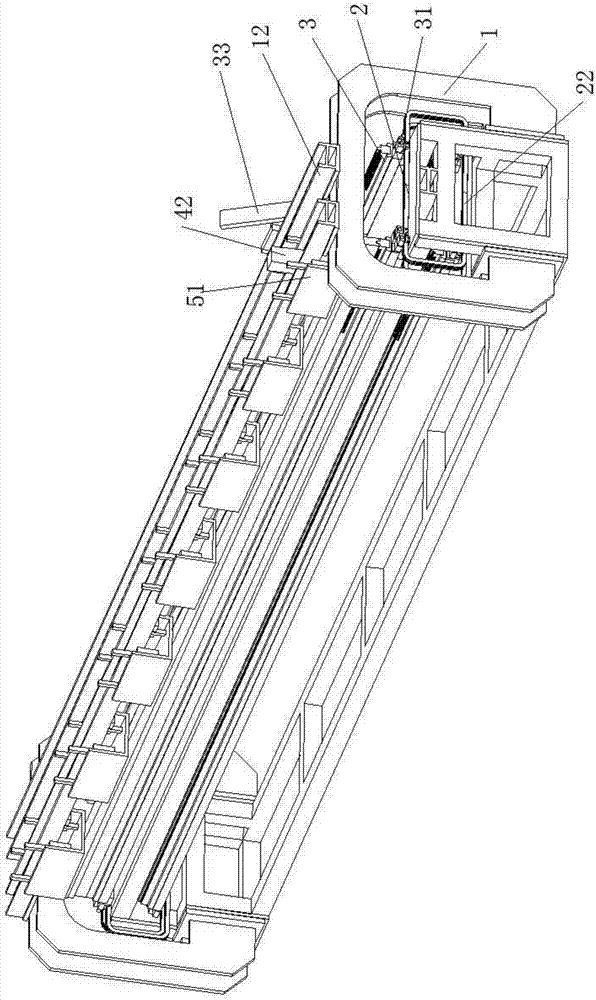

[0022] refer to figure 1 , figure 2 , a hydraulic tube expansion device, including a frame 1, a conveying mechanism, a film arrangement mechanism and a water expansion mechanism, the top of the frame 1 is provided with a bracket 12;

[0023] The delivery mechanism includes an upper slide 2, a mold slide, a first lifting platform 21 and a second lifting platform, the mold slide is slid on the upper slide 2, and the first lifting platform 21 and the second lifting platform The platform is arranged on the frame 1, and the first lifting platform 21 and the second lifting platform are respectively provided with sliding seat jigs 211;

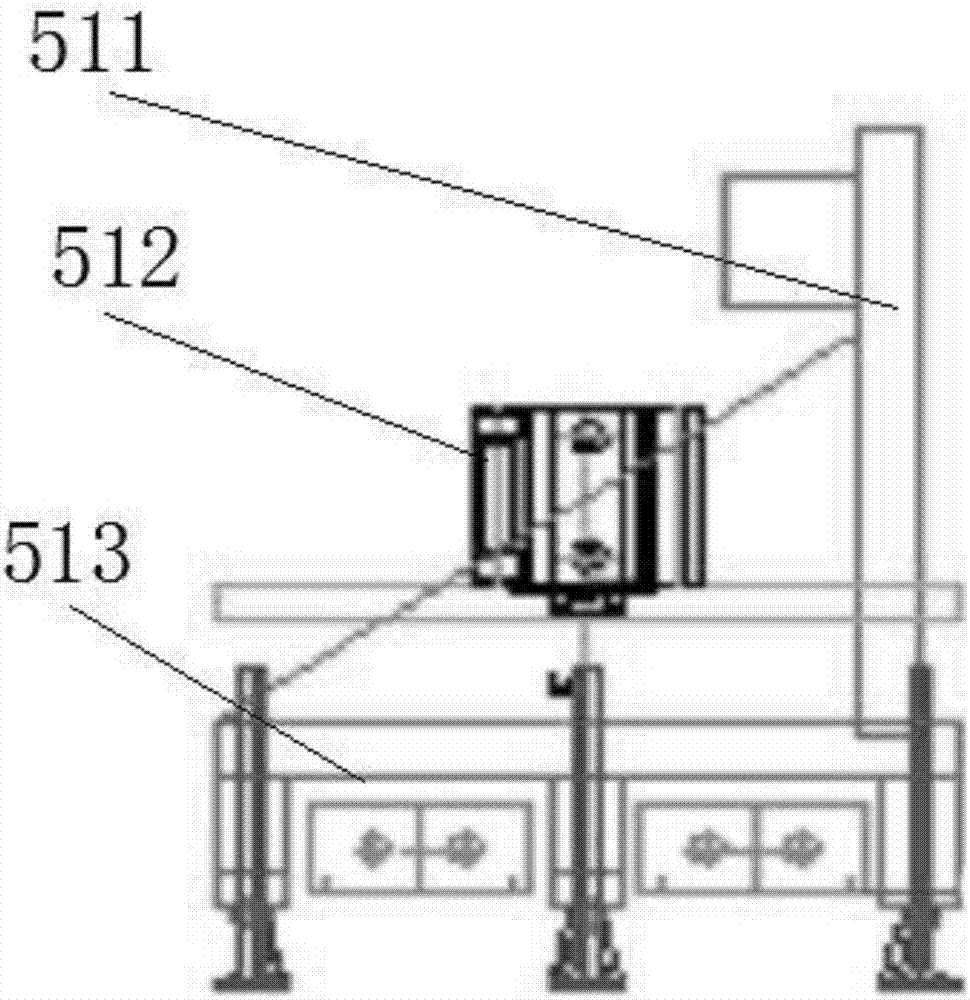

[0024] The sheet arrangement mechanism includes a first lower mold 3, a second lower mold 7 and a mold seat 31, and the first lower mold 3 is fixedly connected to the mold seat 31, and the mold seat 31 is arranged on the first l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com