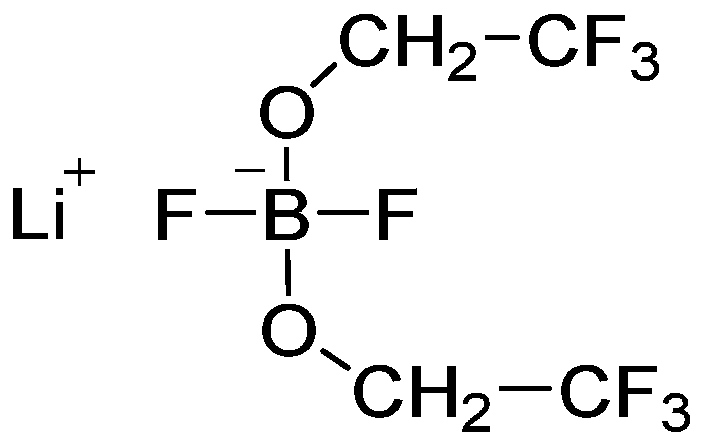

A kind of bistrifluoroethoxy bisfluoroborate lithium salt and lithium-ion battery low-temperature electrolyte and lithium-ion battery containing it

A technology of bis-trifluoroethoxy bis-fluoroborate lithium and lithium-ion batteries, which is applied in secondary batteries, circuits, electrical components, etc., can solve the problem of reduced electrolyte fluidity and ion mobility, inability to infiltrate graphite anode materials, The problems of increasing ion conduction resistance, etc., can achieve the effect of improving lithium ion migration rate, good low temperature capacity retention rate, and reducing surface energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of the positive electrode sheet is as follows: the ternary material LiNi 0.5 co 0.2 mn 0.3 o 2 , superP conductive agent, and PVDF adhesive are uniformly mixed according to 96%:2.0%:2.0% to make a certain viscosity of lithium-ion battery positive electrode slurry, which is coated on the aluminum foil of the current collector, and the coating amount is 0.02g / cm 2 , after drying at 90°C, cold pressing; then trimming, cutting, and slitting; then drying at 90°C for 5 hours under vacuum conditions, welding the tabs, and making a lithium-ion battery positive electrode that meets the requirements.

[0034] The preparation method of the negative electrode is as follows: graphite, conductive agent superP, thickener CMC, and binder SBR are made into slurry at a mass ratio of 96:1.0:1.0:2.0, coated on the current collector copper foil, and heated at 90°C Dry under vacuum, the coating weight is 0.01g / cm 2 ; After trimming, cutting, and slitting, dry at 11...

Embodiment 1

[0038] Lithium salt synthesis process:

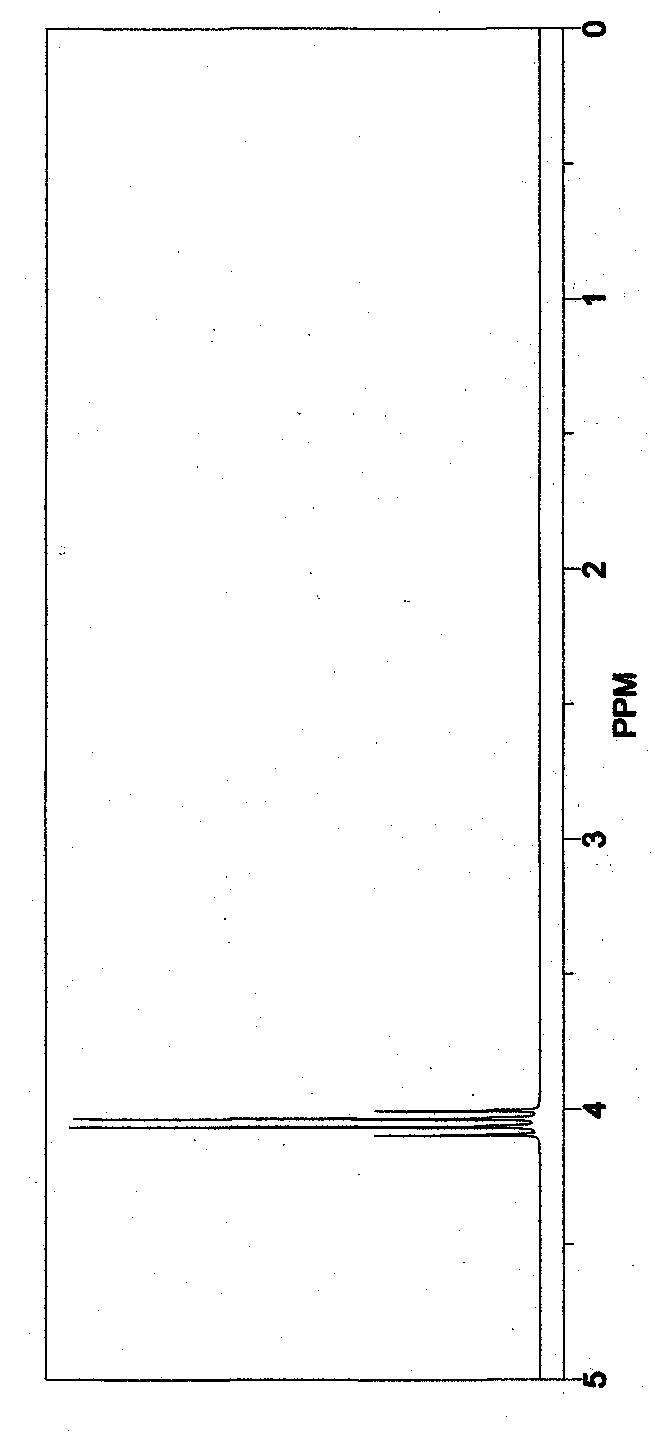

[0039] 100 mL of acetonitrile solvent was added to a 200 mL flask, and 2.59 g of lithium fluoride, 14.19 g of boron trifluoride etherate, 10.0 g of 2,2,2-trifluoroethanol, and 4.25 g of silicon tetrachloride were sequentially added thereto. Reacted at room temperature for 4 hours, then distilled off the solvent under reduced pressure, and precipitated crystals at the same time, washed the crystals with a small amount of acetonitrile solvent after filtration, and dried them in vacuum at 80°C for 4 hours to obtain 16.5 g of white crystals with a yield of 95%; structural formula characterization data: 1H NMR (DMSO-d6, 200 MHz), δ: 4.05 (m, 4H).

Embodiment 2

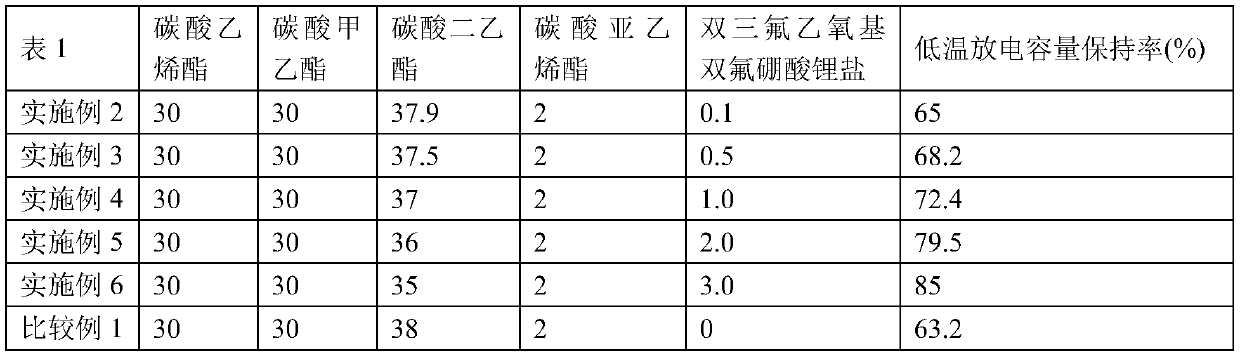

[0041] Preparation of low-temperature electrolyte for lithium-ion batteries:

[0042] Lithium-ion battery low-temperature electrolyte includes: LiPF 6 , ethylene carbonate (EC), ethyl methyl carbonate (EMC), diethyl carbonate (DEC), additive vinylene carbonate (VC) and bistrifluoroethoxy bisfluoroborate lithium salt.

[0043] Ethylene carbonate (EC), ethyl methyl carbonate (EMC), diethyl carbonate (DEC), additive vinylene carbonate (VC) and bistrifluoroethoxy bisfluoroborate lithium salt, by mass ratio: EC : EMC: DEC: VC: bistrifluoroethoxy bisfluoroborate lithium salt=30%: 30%: 37.9%: 2%: 0.1%, mixed to obtain electrolyte solvent, in this electrolyte solvent, dissolve 1mol / LiPF of L 6 , to obtain a non-aqueous electrolyte.

[0044] Preparation of lithium-ion batteries:

[0045] Described lithium-ion battery comprises positive electrode sheet, negative electrode sheet, the separator that is spaced between positive and negative electrode sheet and electrolytic solution of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com