Lithium iron phosphate battery auto-discharge screening method

A lithium iron phosphate battery and screening method technology, applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve the problems that are difficult to eliminate in a short time, and the accuracy is low, so as to shorten the standing time, judge accurately, The effect of zero error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

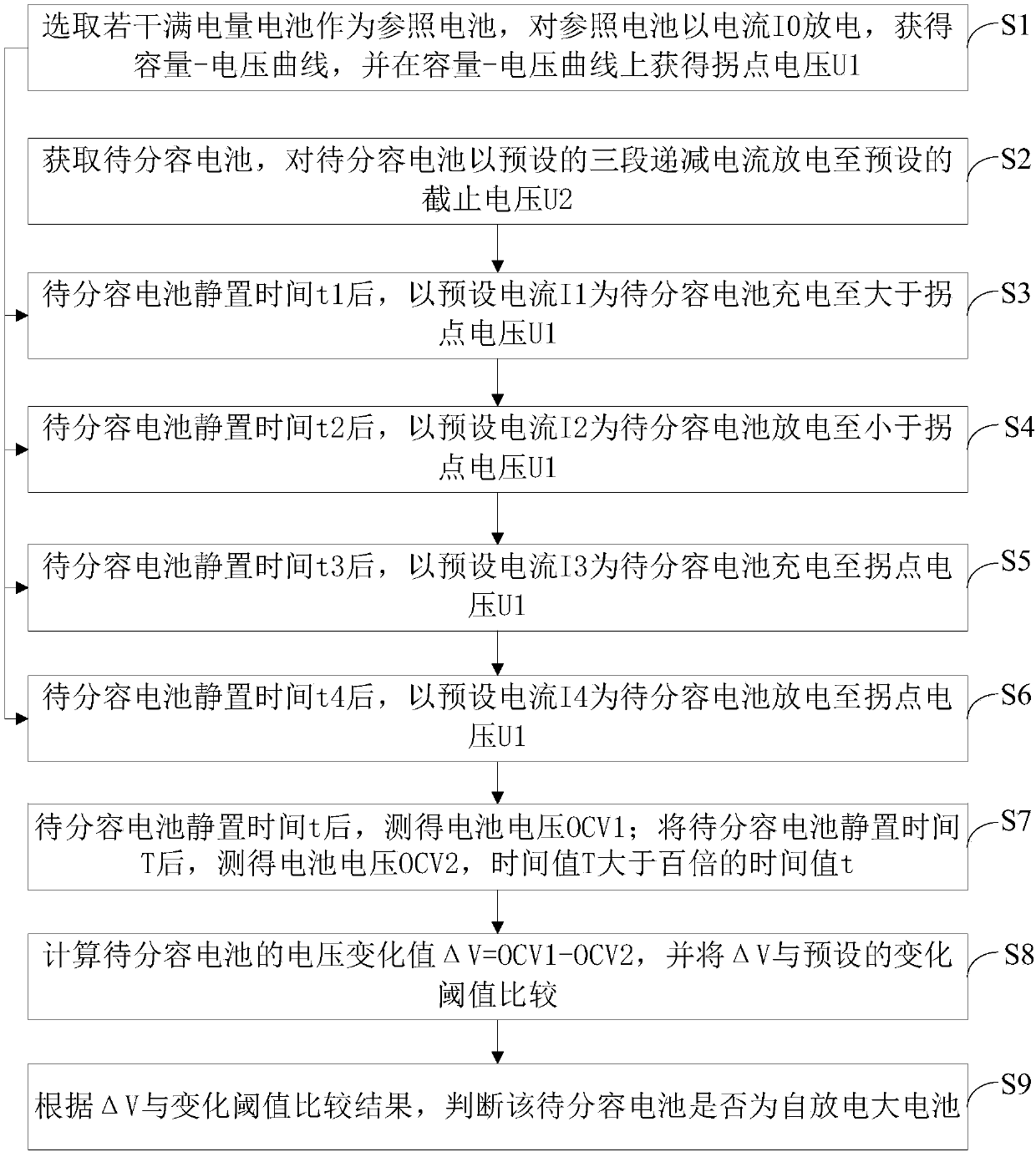

[0027] refer to figure 1 , a self-discharge screening method for lithium iron phosphate batteries proposed by the present invention includes the following steps, and all the following steps are carried out at a temperature of 25±5°C.

[0028] S1. Select a number of fully charged batteries as reference batteries, discharge the reference batteries with current I0, obtain a capacity-voltage curve, and obtain an inflection point voltage U1 on the capacity-voltage curve. In this step, the inflection point voltage is the point where the curvature changes suddenly on the capacity-voltage curve. In this step, I0 is a tiny level current of 0.005C-0.01C.

[0029] S2. Obtain the battery to be divided, and discharge the battery to the preset cut-off voltage U2 with the preset three-stage decreasing current. Specifically, U2 may take on a value of 2.8V. This step is specifically as follows: to treat the divided battery, discharge it to 3.0V with a current of 0.67C-1C, and then discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com