Bridge girder erection machine used for erecting precast beams and bridge girder erection method thereof

A technology of bridge erecting machine and prefabricated beams, which is applied in the direction of erecting/assembling bridges, bridges, bridge construction, etc., which can solve the problems affecting the force of bridge erection, affecting construction efficiency, and greatly affecting the natural environment, so as to reduce the cost of the site environment Requirements, low overall project cost, and good product quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention will be further described below in conjunction with the accompanying drawings.

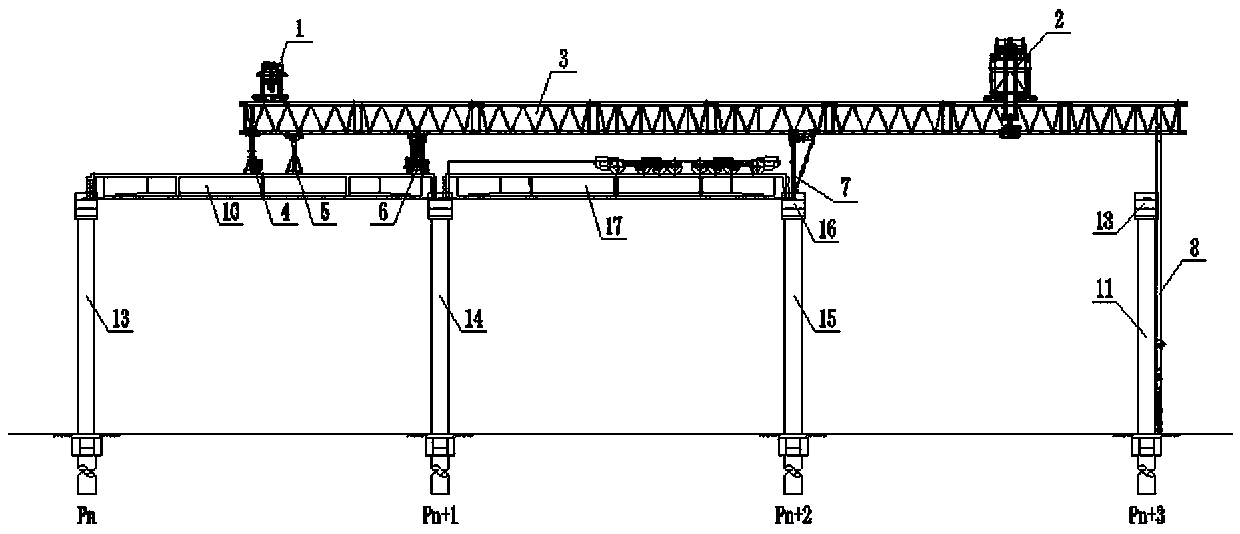

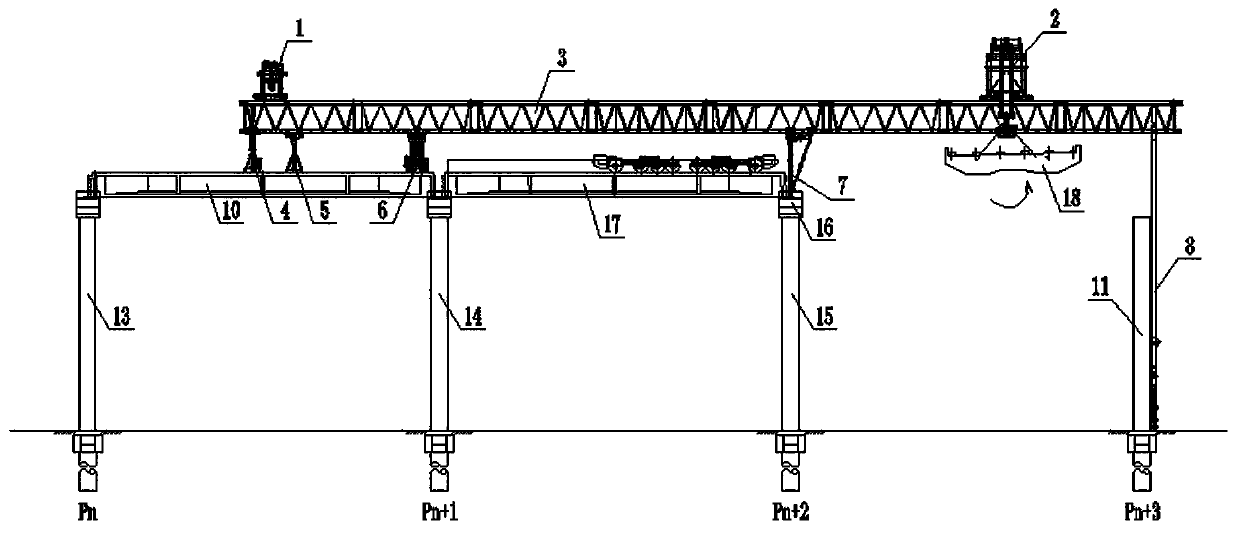

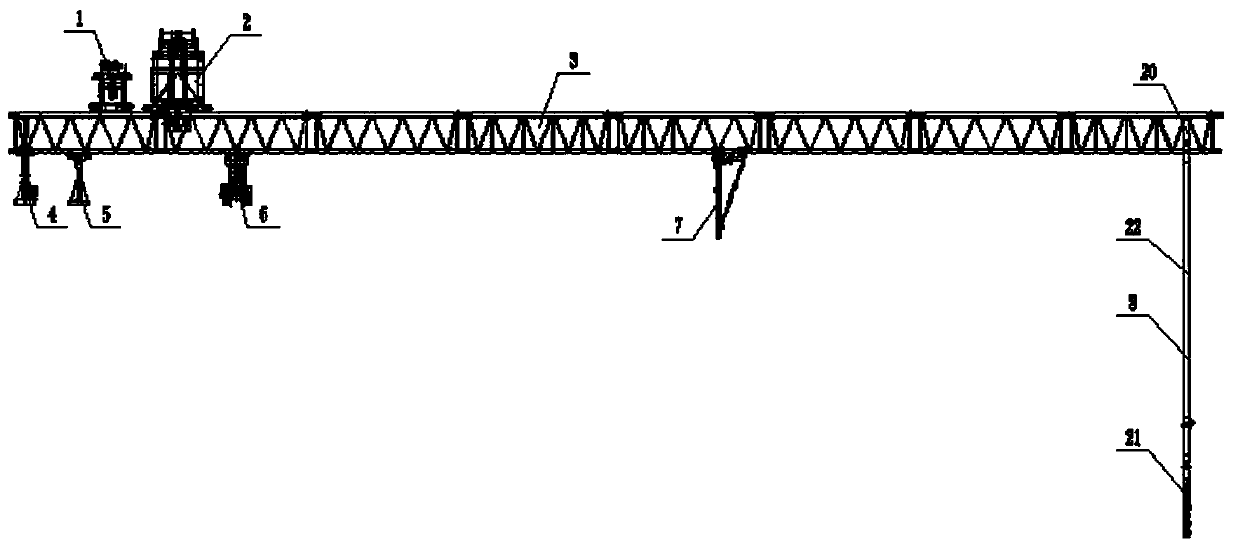

[0063] Such as figure 1 As shown, the bridge erecting machine used includes a machine arm 3 designed symmetrically in both the longitudinal direction and the transverse direction. The belonging machine arm 3 is a double box girder structure. 8. From top to bottom, it includes a connecting rod 20, a long support rod 22 and a bottom leg 21. The connecting rod 20 is detachably connected to the front end of the machine arm 3, and the lower end of the connecting rod 20 is detachably connected to the top of the long support rod 22. The lower end of the long support rod 22 is detachably connected with the bottom leg 21, a jacking mechanism is provided on the bottom leg 21, a top leg 4 is installed at the rear end of the machine arm 3, and a The front outrigger 7 and the rear outrigger 6 that can walk along the longitudinal direction, that is, the construction direction, are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com