Method of controlling coke quality with high proportion weakly caking coal

A technology of coke quality and weak cohesion, applied in the field of coal chemical industry, can solve problems such as conflicts and high cost of coal blending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

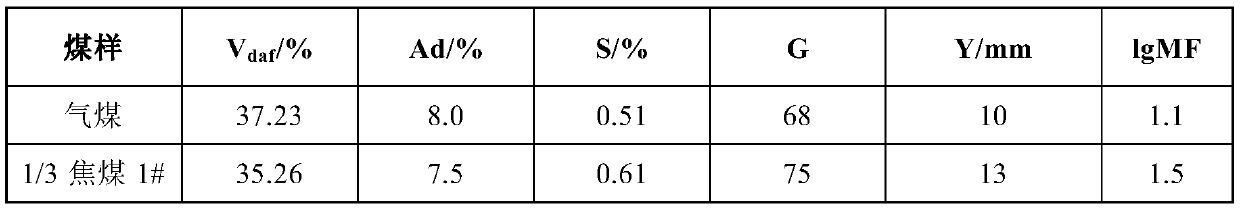

[0028] Coal gas coal used for coking in coking plants (the curve of the position of the upper layer of the colloid body as a function of temperature is a smooth descending type, and other unspecified single coals indicate that their corresponding curves do not present a smooth descending type), fat coal 1#, Fat coal 2#, 1 / 3 coking coal 1# (the curve of the position of the upper layer of the colloid body with temperature changes is a smooth descending type), 1 / 3 coking coal 2# (fluidity lgMF>3.0), coking coal, lean coal (colloid The curve of the position of the upper layer of the body with the change of temperature is a smooth descending type), and the specific indicators are as follows:

[0029] 1 single coal quality

[0030]

[0031]

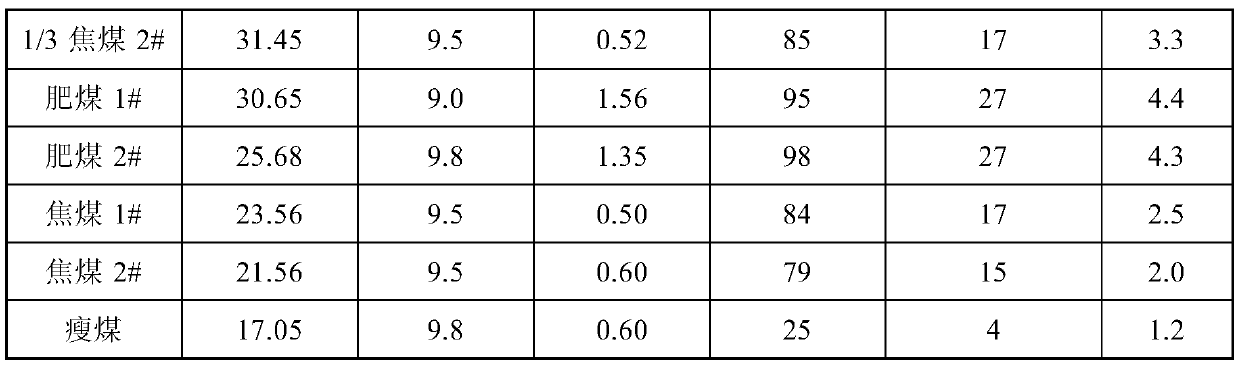

[0032] Table 2 Microstructure of single coal coke

[0033]

[0034] Step 1: Determine that gas coal, 1 / 3 coking coal 1# and lean coal are weak coking coals.

[0035] Step 2: Determine the coal type with fluidity lgMF>3.0, that is, 1 / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal properties | aaaaa | aaaaa |

| thermal properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com