Air-cooled condenser dust accumulation status monitoring and cleaning control system and its control method based on convolutional neural network and image recognition

A convolutional neural network and air-cooled condenser technology, which is applied in image analysis, image data processing, instruments, etc., can solve problems such as endangering the safe operation of air-cooled units, reducing operating economy, and reducing the heat transfer performance of air-cooled condensers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below using the drawings and specific embodiments.

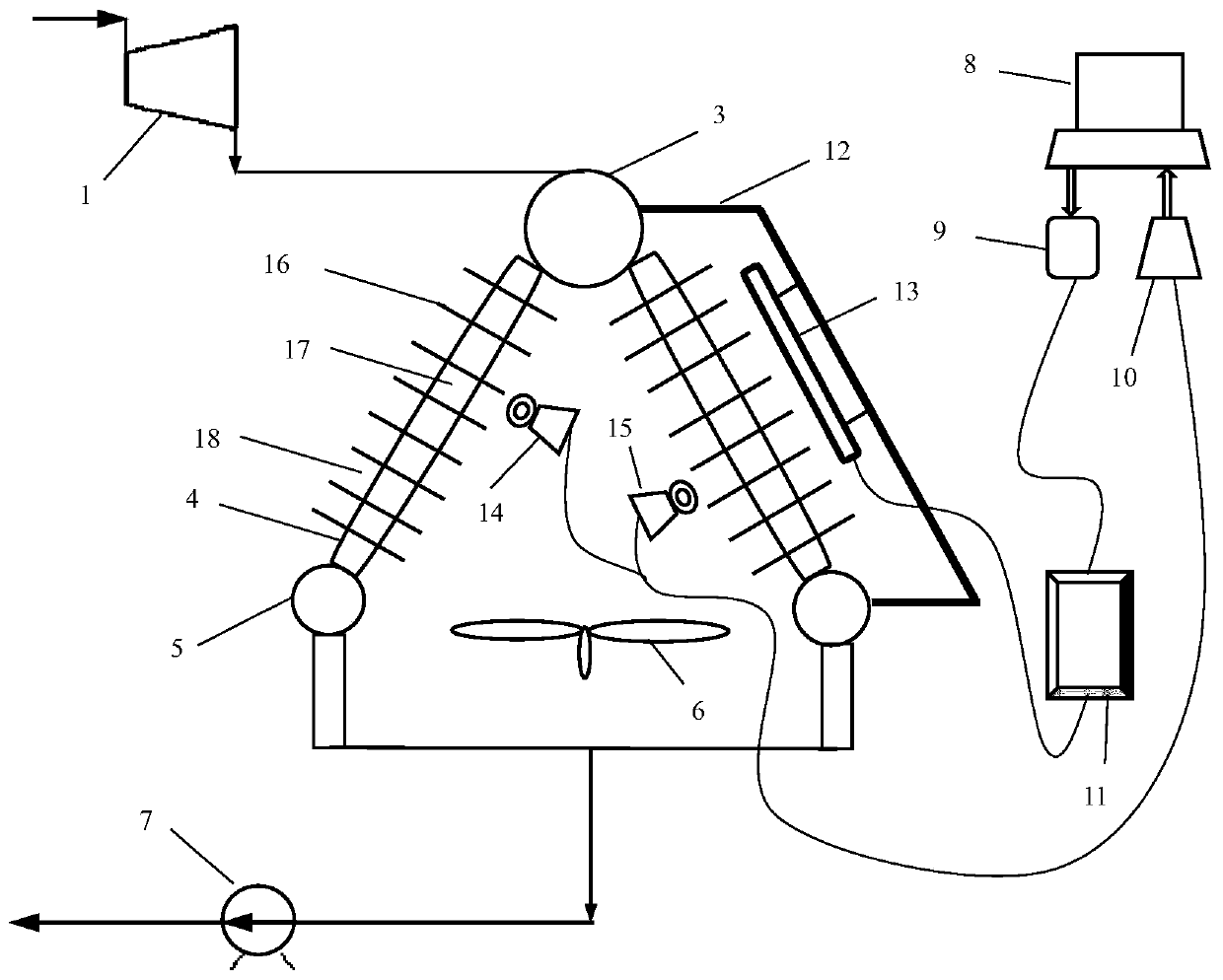

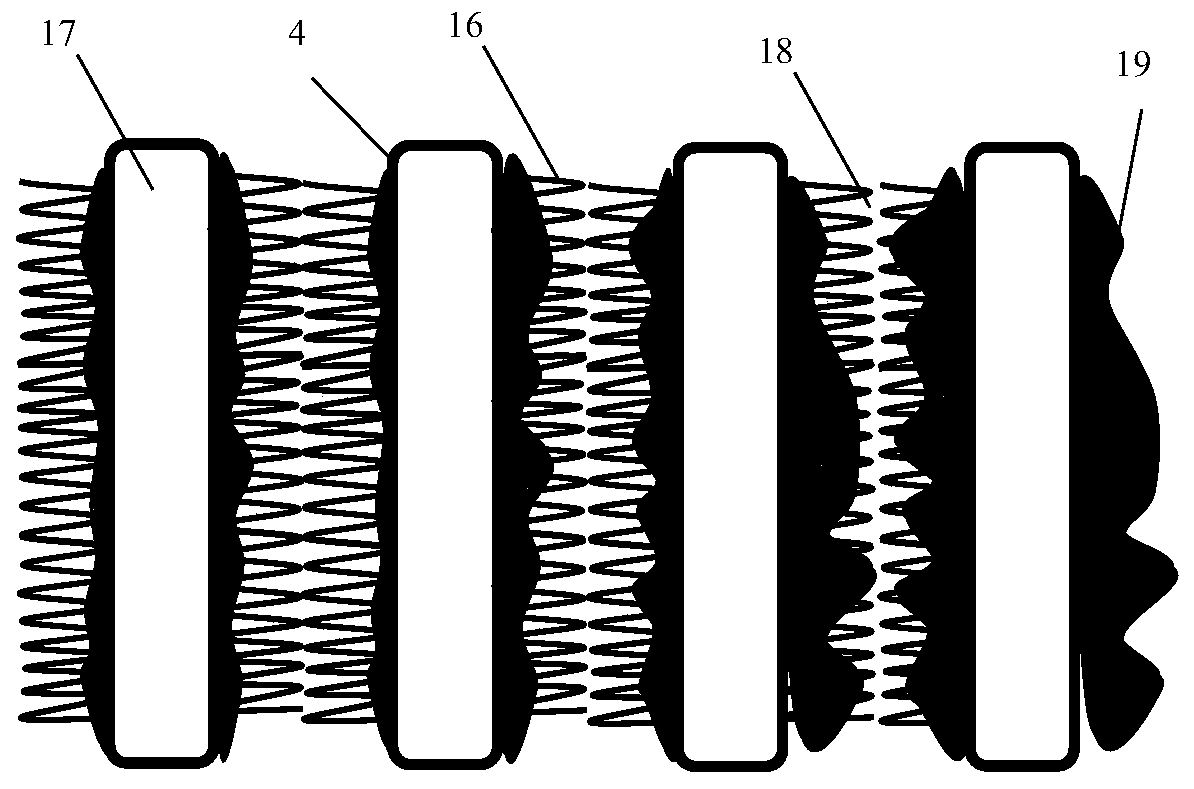

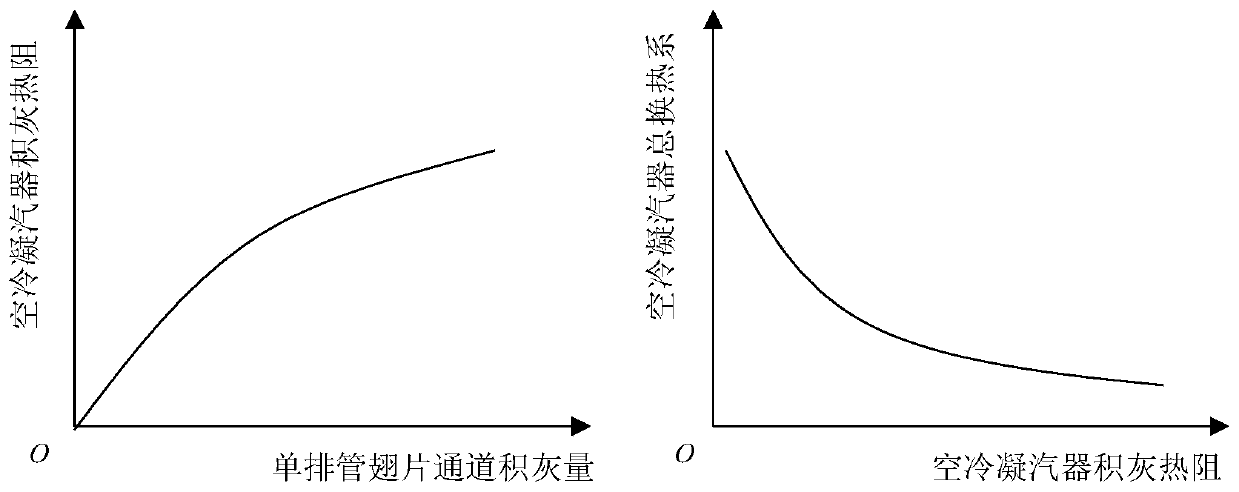

[0054] refer to figure 1 , an air-cooled condenser dust accumulation state monitoring and cleaning control system based on convolutional neural network and image recognition of the present invention, including the output end of the steam turbine 1 communicating with the input end of the exhaust steam distribution pipe 3, and the output end of the exhaust steam distribution pipe 3 The single row pipe base pipe 4 of the air-cooled condenser is connected to the input end of the condensate tank 5, and the output end of the condensate water tank 5 is connected to the input end of the condensate water pump 7; the first visible light camera 14 is placed inside the single row pipe base pipe 4 of the air-cooled condenser , located at the top of the air-cooling fan 6, the second visible light camera 15 is placed on the other side of the inner side of the single row tube base pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com