Method for preparing water-based acrylic resin by continuous extrusion process and production equipment for realizing the method

A water-based acrylic, extrusion technology, applied in the direction of ink, coating, household utensils, etc., can solve the problems of high difficulty in molecular weight distribution control, high system viscosity, low and narrow molecular weight distribution, etc., to achieve molecular weight and distribution controllable, stay The effect of uniform time and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032]Preparation of dispersion resin for general-purpose water-based ink (acid value: 215±5mgKOH / g, Tg=80±5℃, weight average molecular weight=9000±1000Da),

[0033] 1. Formula

[0034] Butyl acrylate (BA) 7.09 parts by weight

[0035] Styrene (ST) 50.39 parts by weight

[0036] Acrylic acid (AA) 25.47 parts by weight

[0037] Methyl methacrylate (MAA) 9.22 parts by weight

[0038] Molecular weight regulator (mercaptopropionic acid) 0.50 parts by weight

[0039] Initiator (benzoyl peroxide) 3.00-8.00 parts by weight

[0040] 2. Preparation

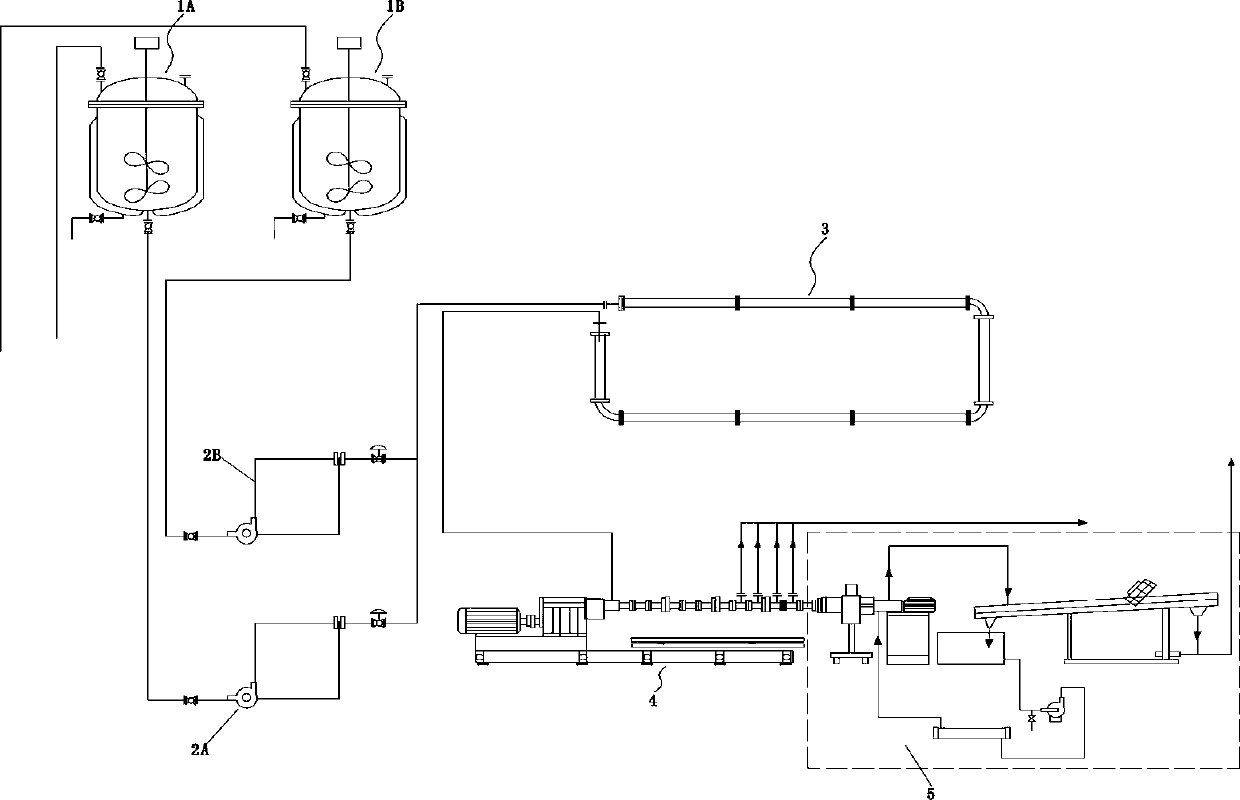

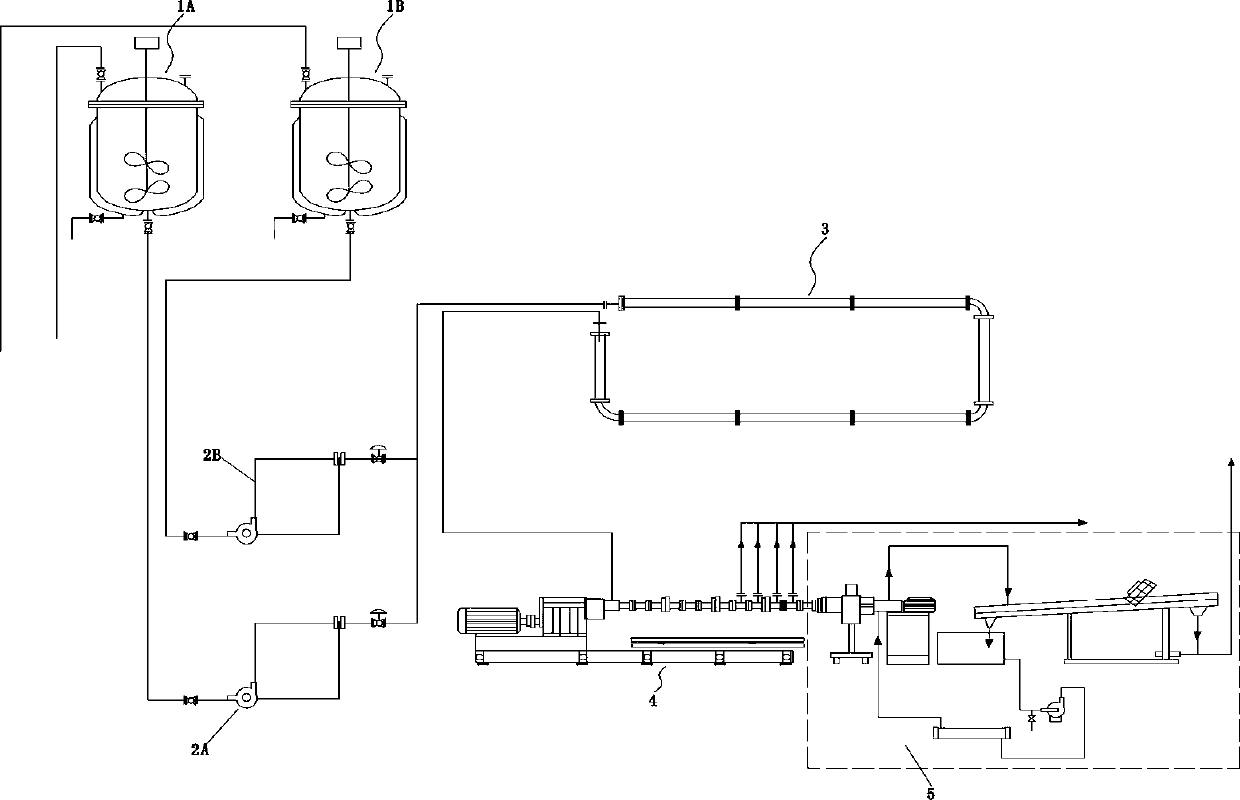

[0041] (1) if figure 1 As shown, according to the above formula, butyl acrylate, styrene, acrylic acid and methyl methacrylate are injected into the preparation tank 1A through vacuum, and after stirring for 10 minutes, the metered benzoyl peroxide and mercaptoethanol are added from the preparation tank The feeding funnel of the tank is added to the preparation tank, and the cooling water at 7°C is circulated in the jacket of the pr...

Embodiment 2

[0048] Preparation of acrylic resin for aqueous varnish emulsion polymerization (acid value: 215±5mgKOH / g, Tg=120±5℃, weight average molecular weight=3000±1000Da)

[0049] 1. Formula

[0050] Styrene (ST) 50.20 parts by weight

[0051] Acrylic acid (AA) 25.47 parts by weight

[0052] 20.33 parts by weight of methyl methacrylate (MAA)

[0053] Molecular weight regulator (mercaptopropionic acid) 1.00-2.00 parts by weight

[0054] Initiator (tert-butyl peroxide) 1.00-2.00 parts by weight

[0055] 2. Preparation

[0056] The preparation method is the same as in Example 1.

Embodiment 3

[0058] Preparation of water-based acrylic resin for carbon black or benzene-free binder (acid value: 215±5mgKOH / g, Tg=120±5℃, weight average molecular weight=18500±1000Da)

[0059] 1. Formula

[0060] 4.08 parts by weight of isobutyl methacrylate

[0061] 32.21 parts by weight of methacrylic acid (MAA)

[0062] Methyl methacrylate (MMA) 61.27 parts by weight

[0063] Molecular weight regulator (mercaptopropionic acid+mercaptoethanol) 0.10-0.49 parts by weight

[0064] Initiator (BPO) 1.00-1.95 parts by weight

[0065] 2. Preparation

[0066] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com