A kind of polymer cement mortar and its preparation method and construction method

A cement mortar and construction method technology, applied in the field of building materials, can solve the problems of easy delamination and drumming, high brittleness, easy crushing, etc., and achieve the effect of improving the richness of colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The present disclosure also provides a method for preparing polymer cement mortar, the preparation method comprising: respectively preparing powder and liquid materials according to the ratio of the polymer cement mortar provided by the present disclosure, and the powder and liquid materials are prepared according to the weight ratio For (1~3):1 mixing.

[0047] The present disclosure also provides a construction method of polymer cement mortar, the construction method comprising:

[0048] a. Brush the liquid material provided by the present disclosure on the layer to be constructed, spread the mortar provided by the present disclosure above the liquid material, and dry it to obtain a mortar layer;

[0049] b. Polishing the obtained mortar layer to obtain a first mortar-polished layer with a thickness not greater than 2 mm.

[0050] The construction method of the present disclosure can obtain a mortar grinding layer with a thickness of less than 2 mm. The mortar grindi...

Embodiment 1

[0064] 1. Color mortar formula:

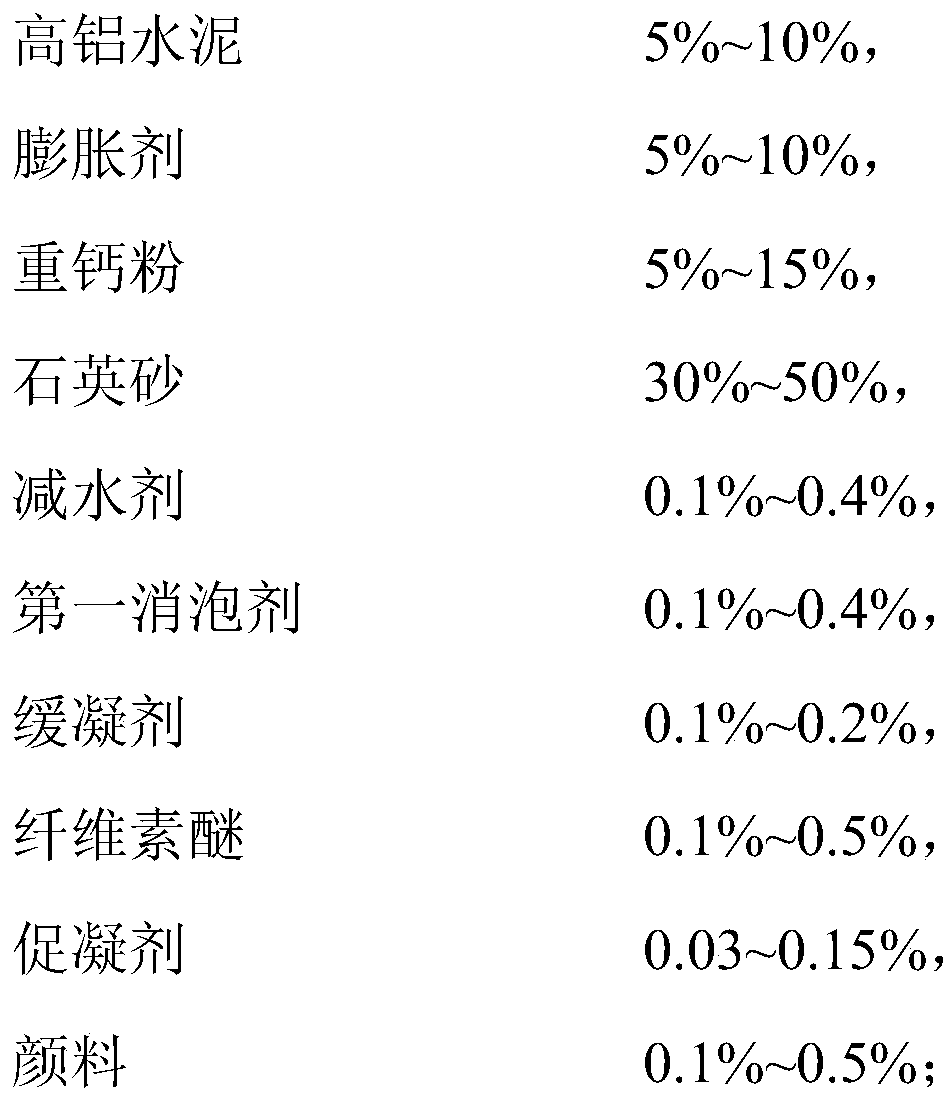

[0065] Powder (based on the weight of the powder):

[0066] White cement (No. 525 Pu Si, Albo) 30%,

[0067] High alumina cement (Kenos CA-70) 5%,

[0068] Expansion agent (Zhengzhou Jianwen Technology, calcium sulfoaluminate-calcium oxide concrete expansion agent) 5%,

[0069] Heavy calcium powder (Hebei Shengnuo building materials, particle size is 400 mesh) 15%,

[0070] Quartz sand (Yihang, Lingshou County, the particle size is 40-70 and 70-140 according to 1:1 compounding) 44.02%,

[0071] Water reducer (Xindadi, polycarboxylate water reducer) 0.1%,

[0072] Defoamer (MUNZING, high carbon alcohol defoamer, P803) 0.2%,

[0073] Retarder (Shanghai Huiyu, L+ tartaric acid) 0.13%,

[0074] Cellulose ether (Henan Tiansheng, methyl cellulose ether, MC-400) 0.1%,

[0075] Coagulant (Shanghai Huiyu, Lithium Carbonate) 0.15%,

[0076] Pigment (Bayer pigment, composed of iron oxide) 0.3%.

[0077] Liquid material (based on the weight of li...

Embodiment 2

[0093] The mortar material used in embodiment 2 is the same as that in embodiment 1, except that the proportioning ratio is different.

[0094] 1. Color mortar formula:

[0095] Portland cement 32%,

[0096] High alumina cement 8%,

[0097] Bulking agent 8%,

[0098] Heavy Calcium Powder 10%,

[0099] Quartz sand 40.88%,

[0100] Water reducer 0.12%,

[0101] Defoamer 0.25%,

[0102] Retarder 0.16%,

[0103] Cellulose ether 0.16%,

[0104] Coagulant 0.13%,

[0105] Pigment 0.3%.

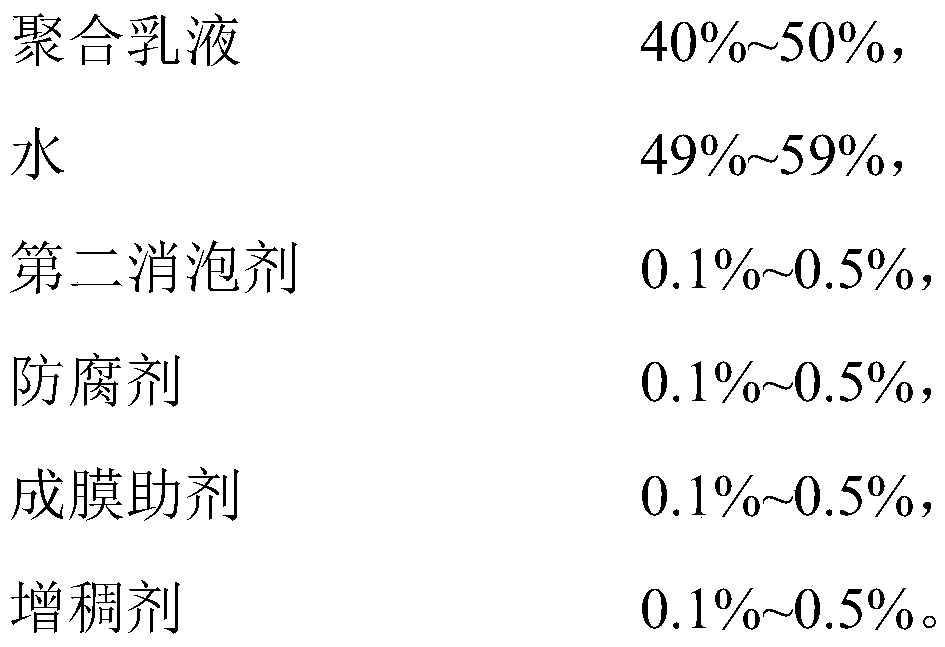

[0106] Liquid formula:

[0107] Polymeric Emulsion 50%,

[0108] Defoamer 0.13%,

[0109] Preservatives 0.16%,

[0110] Coalescent 0.15%,

[0111] Thickener 0.18%,

[0112] Water 49.38%.

[0113] 2. Ground construction:

[0114] 1) Use a dust-free grinder to grind the base layer, remove the floating slurry and stains on the ground, and repair the hollowing and cracking of the base layer.

[0115] 2) Apply the liquid material evenly on the ground with a paint roller;

[0116] 3) Aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com