Lacquered wood press-attaching door and preparation method

A paint and board pressing technology, applied in door leaf, window/door, manufacturing tools, etc., can solve the problem of easily damaged hinge or the connection between hinge and door frame, it is difficult to achieve high-quality three-dimensional surface decoration, the door leaf is not beautiful enough, etc. problem, to achieve the effect of good appearance, easy assembly line processing, and saving production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

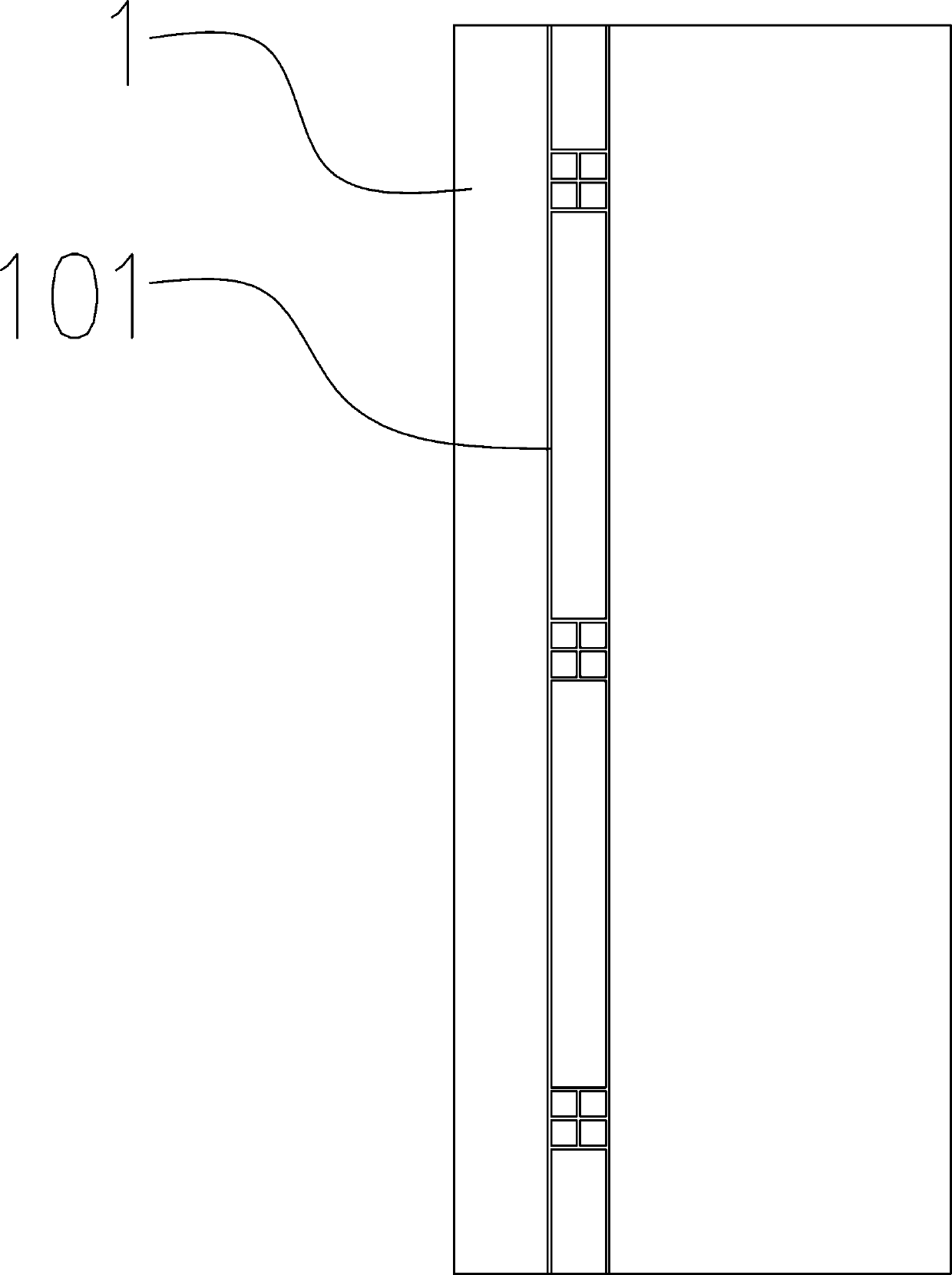

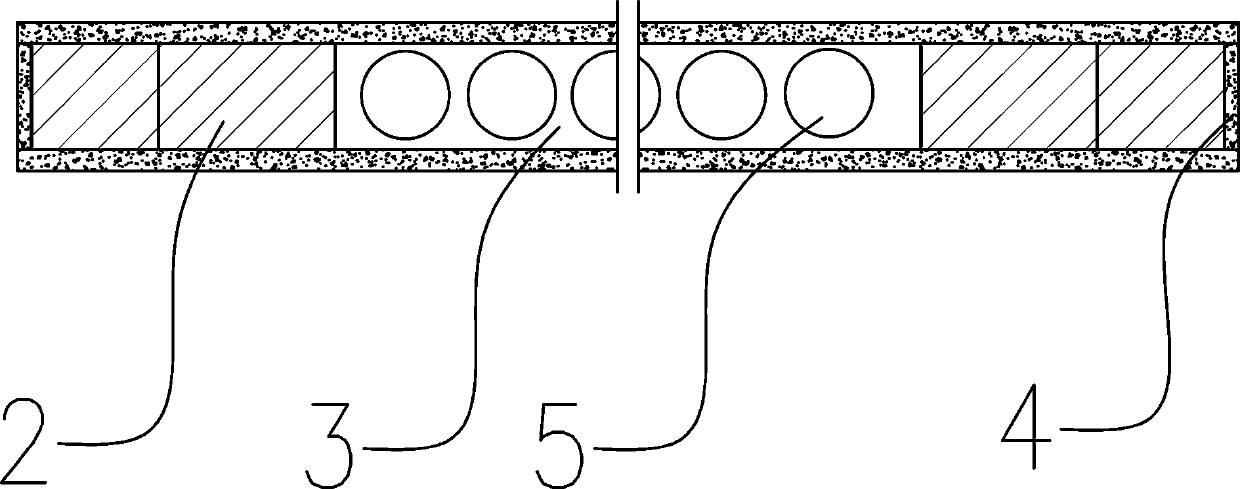

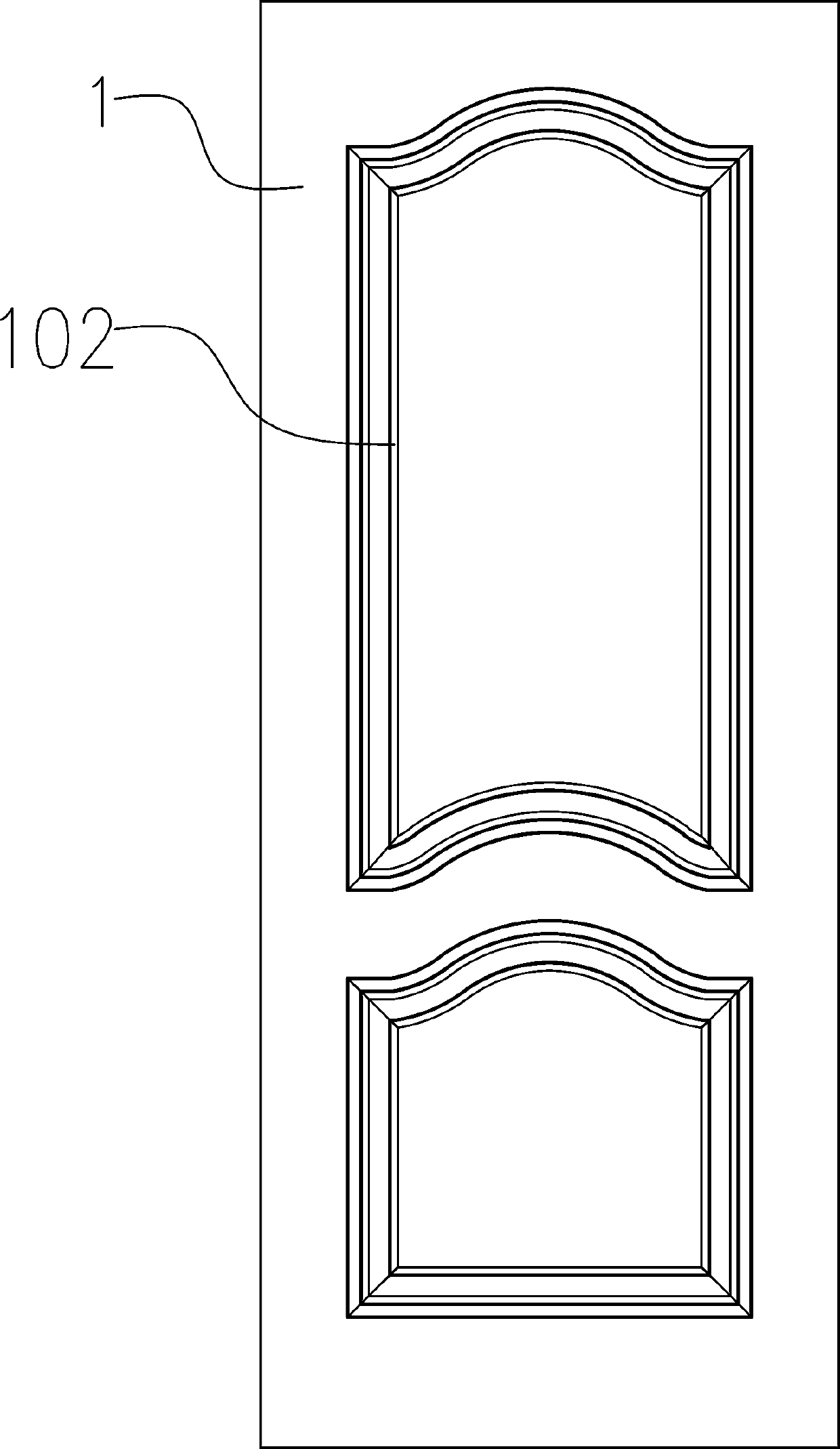

[0042] Such as Figure 1~4 Among them, a painted board press-attached door, the door leaf includes a painted panel 1, a door leaf core board and a same-color veneer edge banding, the paint panel 1 is bonded to the door leaf core board, and the same-color veneer edge banding is bonded to the periphery of the door leaf. With this structure, the spraying steps can be reduced, and the production process can be shortened.

[0043] In a preferred solution, the painted panel 1 is a finished panel with finishes and paint on the surface. On the surface of paint panel 1, be provided with the flexible paint coating that can bend, be preferably No. 501 of water-based UV light-curable primer, No. 502 of water-based UV light-curable finish paint, adopt UV light-curable environmental protection paint, on the paint board such as specification 2440 ×1220×3~25mm, the surface is pasted with natural 30 silk solid wood veneer, the surface is rolled by the UV production line, dried by rolling twic...

Embodiment 2

[0051] On the basis of Example 1, a preparation method for preparing the above-mentioned painted board press-fit door comprises the following steps:

[0052] s1, prepare the paint panel 1;

[0053] In preferred scheme, the step of preparing paint panel 1 is:

[0054] Plain board treatment, sanding by sanding machine, sanding times are two times, front 240 mesh belt sanding, rear 320 mesh belt sanding, UV roller coating equipment as the first primer, coating amount 25 ±2.5g / square meter, turn on the drying UV lamp and semi-dry lamp, dry for 1min, and the drying temperature is 55°C~65°C;

[0055]The second UV roller coating, the coating amount is 25±2.5g / square meter, the drying UV lamp is turned on and the full dry lamp is turned on, drying for 1min, and the drying temperature is 55°C~65°C;

[0056] Sanding with a sander, with a 400-mesh abrasive belt in the front and a 400-mesh abrasive belt in the rear;

[0057] The third UV roller coating, the coating amount is 25±2.5g / sq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com