Recovery device for selective laser melting recovered powder

A technology for laser selective melting and powder recovery, applied in additive processing and other directions, it can solve the problems of parts defects, different sizes, and inability to separate metal powders, so as to improve the quality, prevent the powder concentration from being too high, and improve the powder blowing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

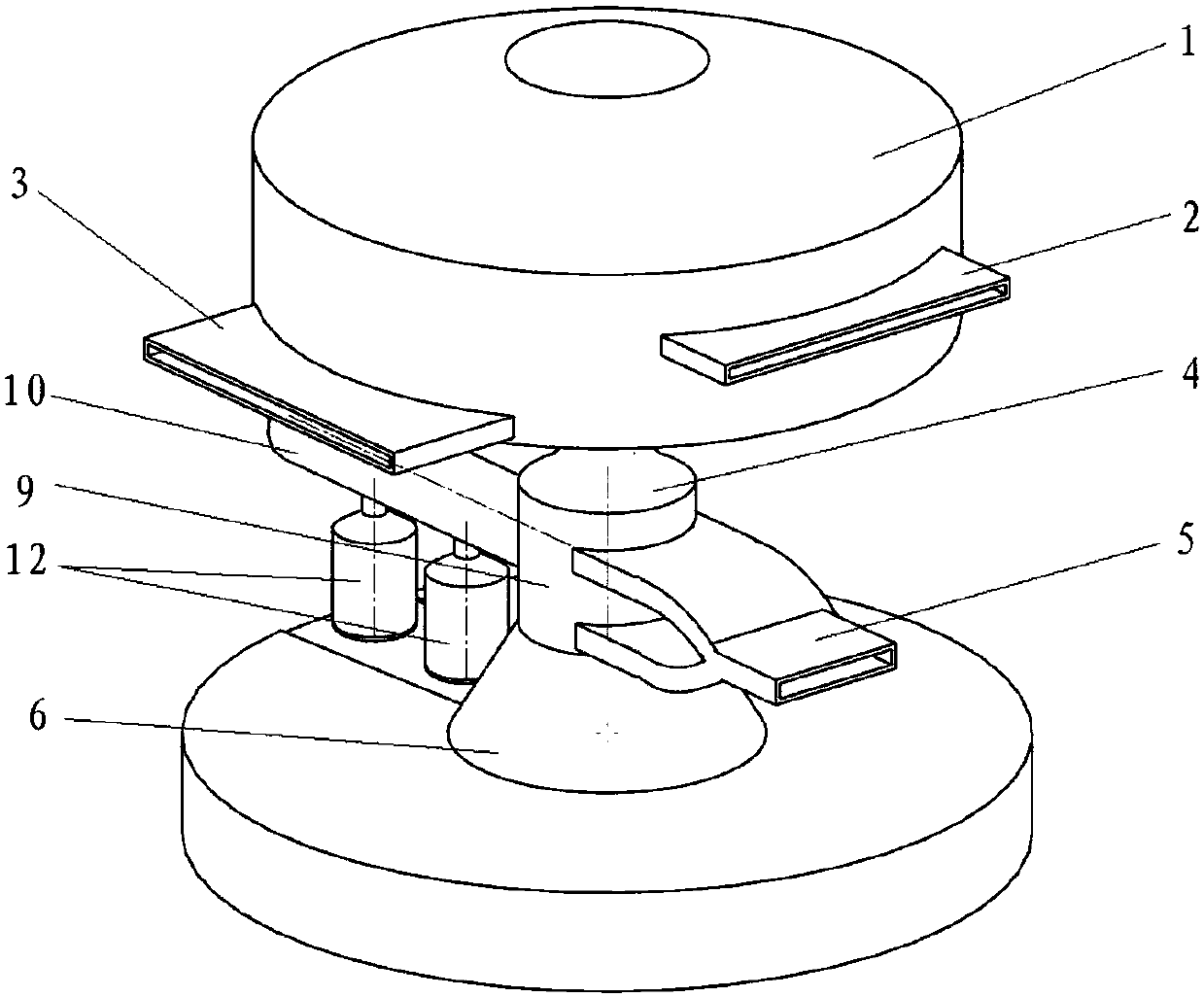

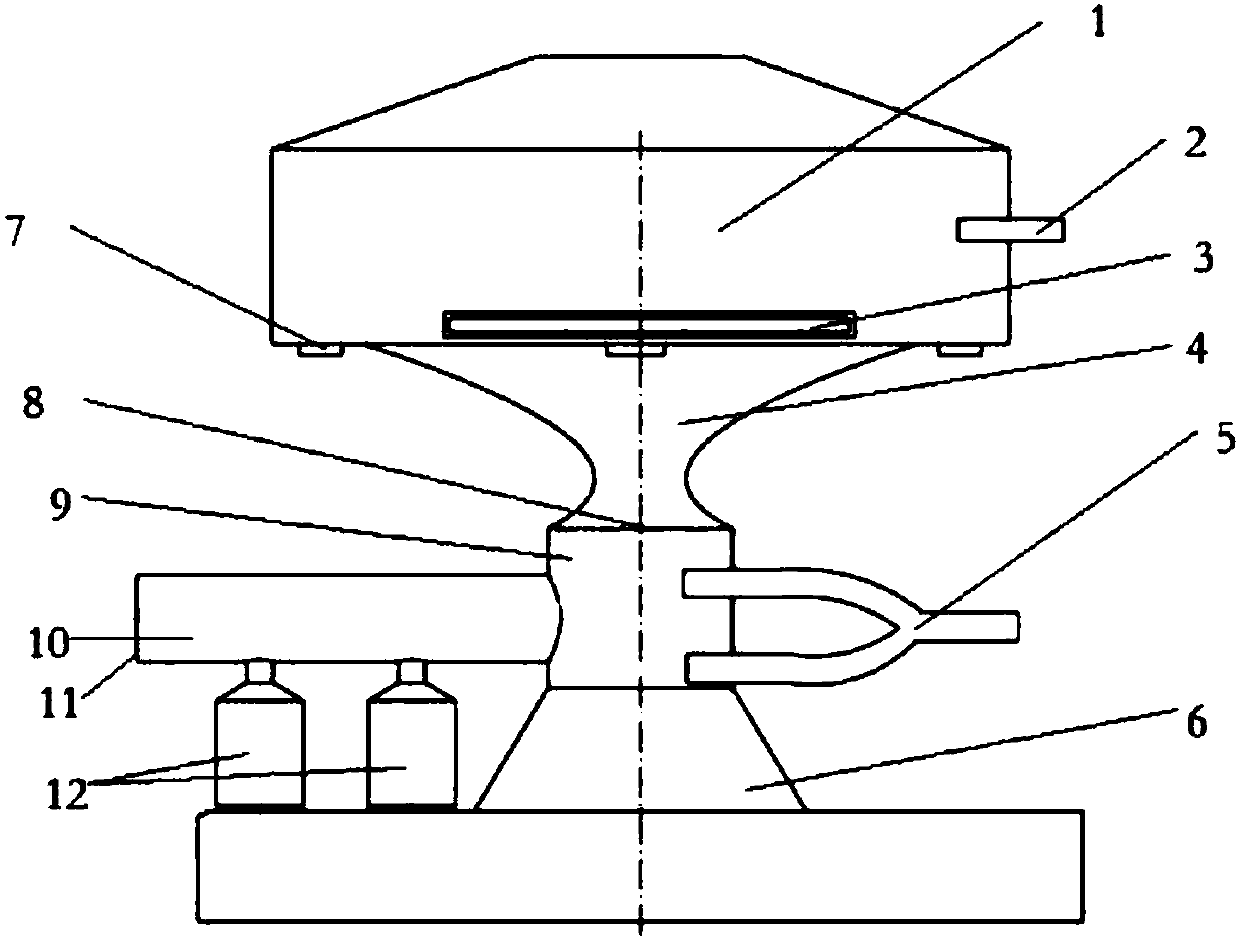

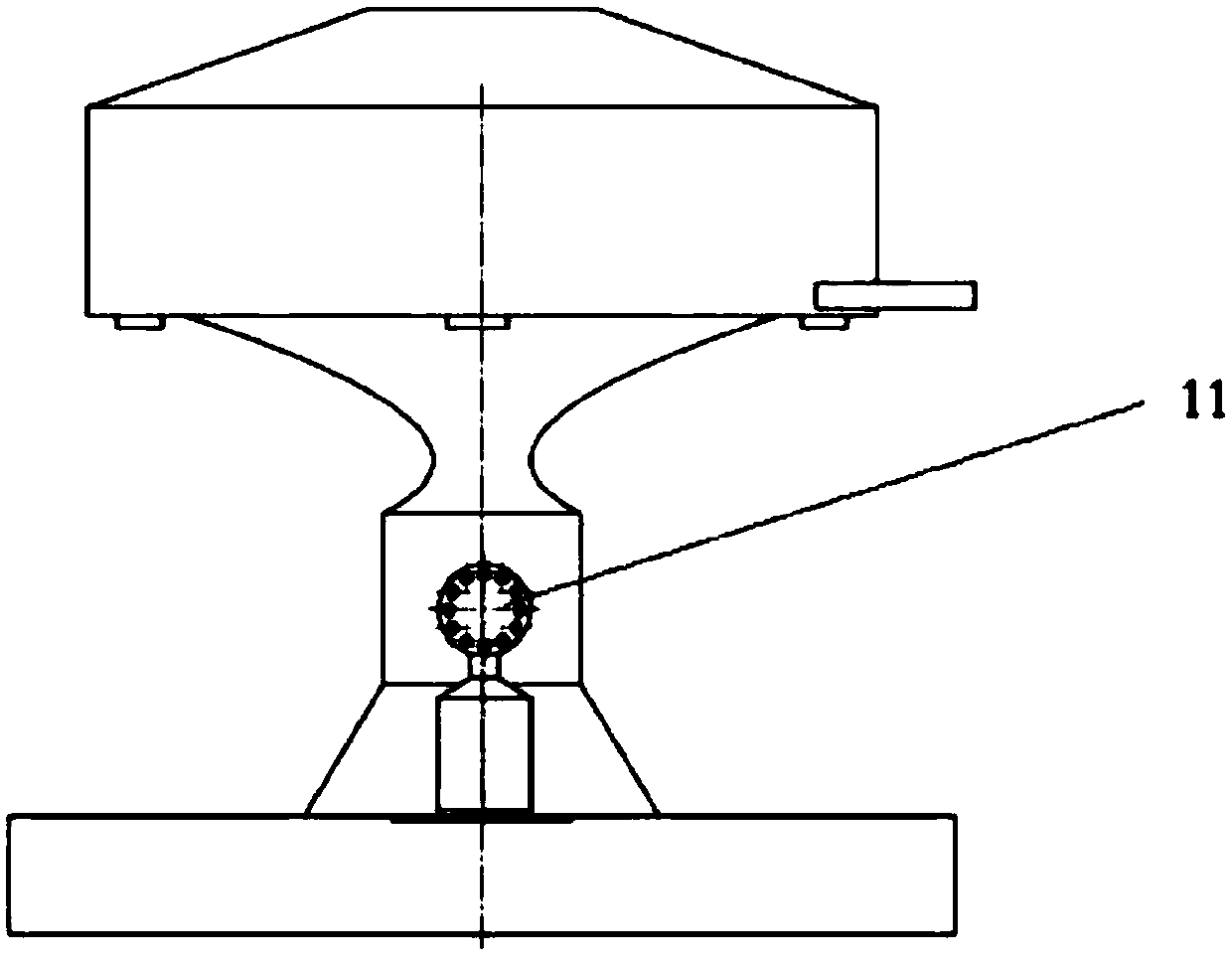

[0030] Refer to attached Figures 1 to 5 As shown, the present invention is aimed at the recycling device for laser selective melting of recycled powder, which includes a powder sieving cabin 1, a powder falling cabin 4, a powder blowing cabin 9 and a base 6 arranged in sequence from top to bottom.

[0031] The sieving cabin 1 is provided with a sieve, which is used to coarsely sieve the powder recovered from laser selective melting. A preferred embodiment is that the powder sieving cabin 1 includes two layers of screens arranged up and down, and the aperture of the upper screen 14 is greater than the aperture of the lower screen 13, such as the mesh number of the upper screen is 100 mesh, which is used for screening The mesh size of the lower sieve is 270 mesh, which is used to sieve the particles above 53 μm, so the particles falling into the powder falling cabin 4 are metal powder and waste residue below 53 μm.

[0032] In this embodiment, the sidewall of the powder sievin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com