Brick tea pressing method, brick tea pressing device and brick tea mold

A tea brick and mold technology is applied to the tea brick pressing method, pressing device and mold, and the production field of brick tea, which can solve the problems of uneven movement of the lock bolt, different pressing thicknesses, and tilting of the cover plate, so as to avoid the uneven movement and heavy weight. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

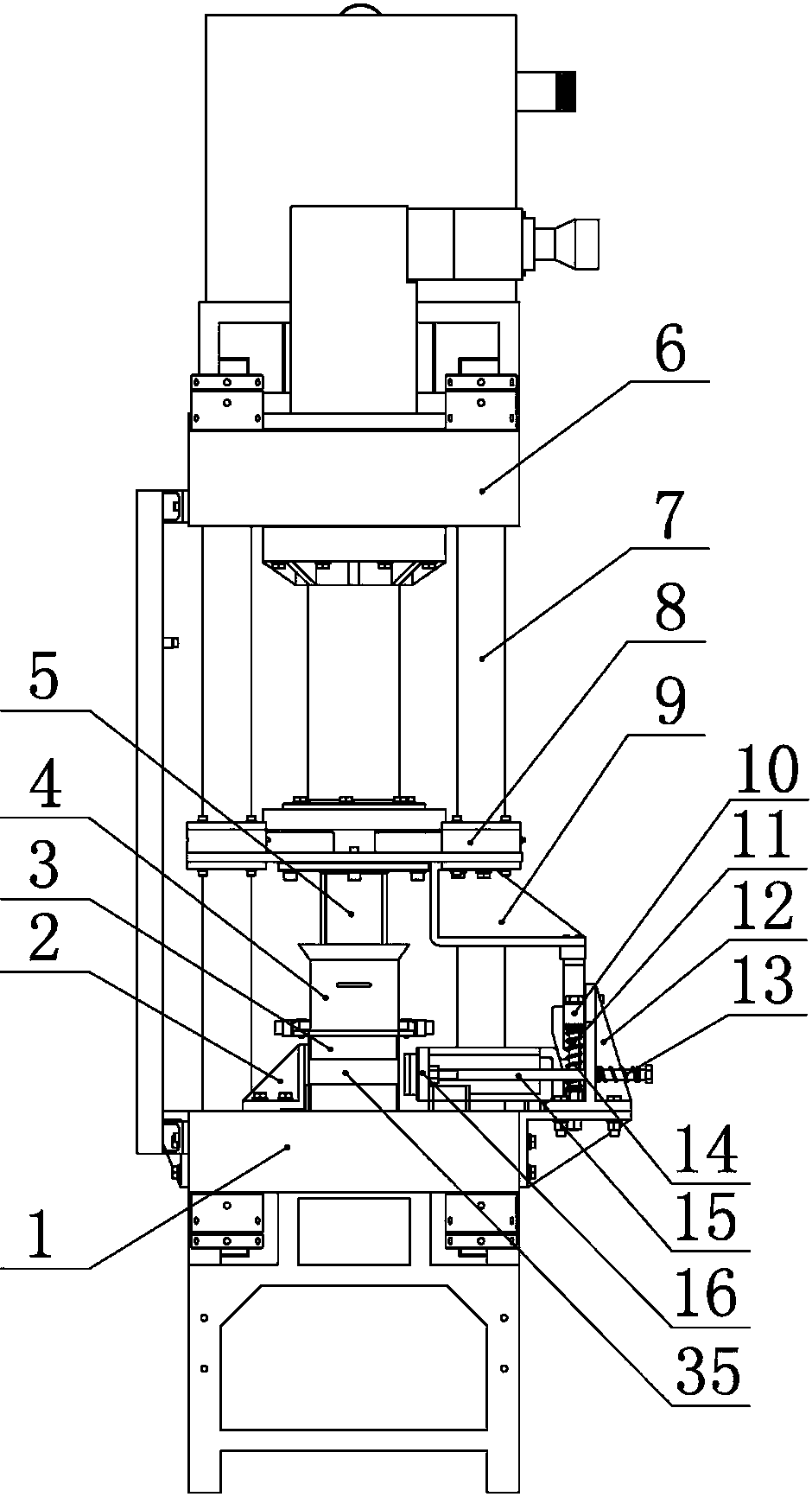

[0038] Depend on figure 1 , figure 2 As can be seen, a kind of tea brick pressing method, it comprises the following steps:

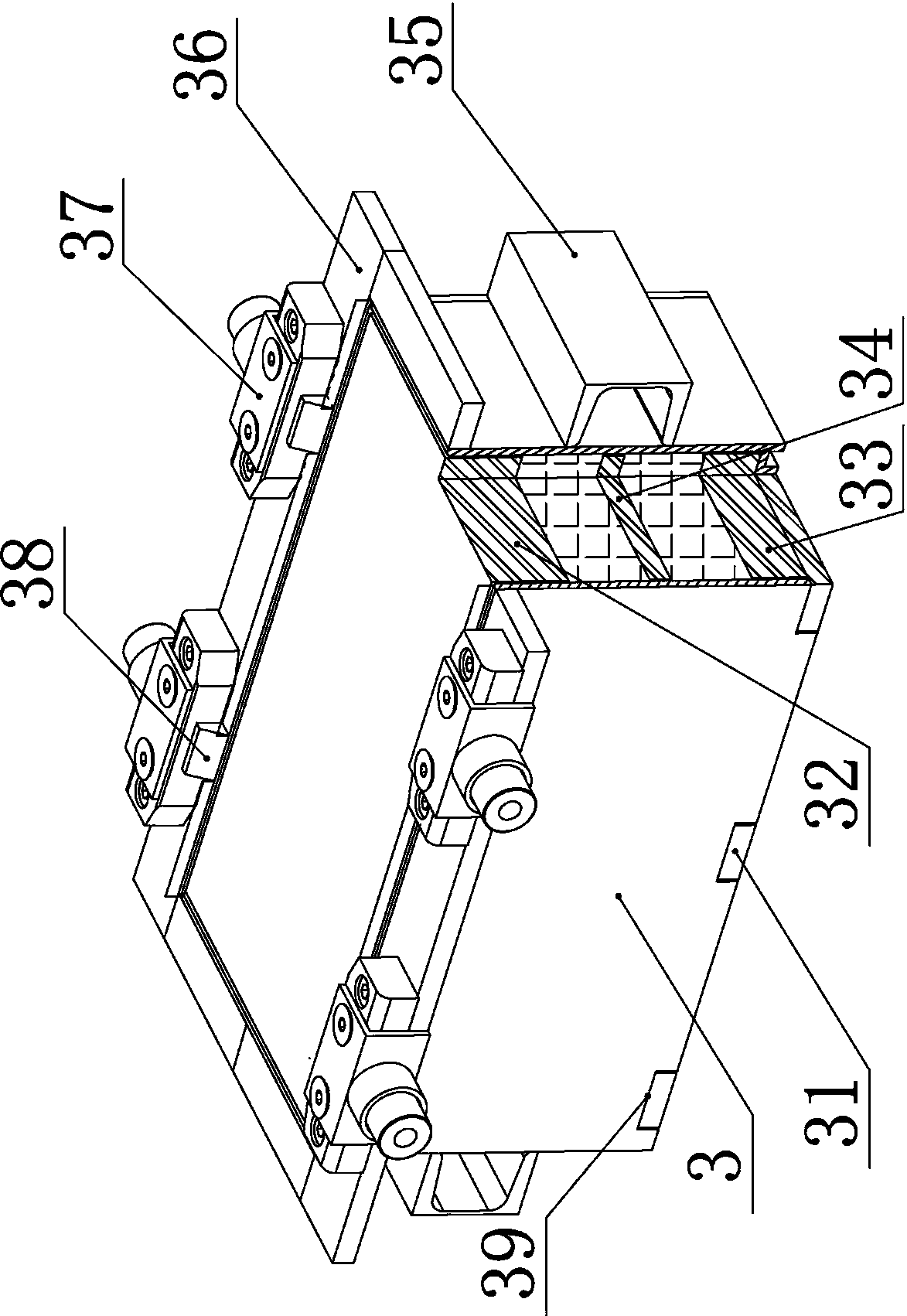

[0039] (1) Sleeve: Set the tea pot 4 above the tea brick mold 3 with the bottom plate 33 inside (the tea brick mold 3 is in the unlocked state), and arrange the tea brick molds 3 with the tea pot 4 in order under the thrust of the propeller to transport;

[0040] (2) One-time tea filling: when the tea brick molds 3 equipped with tea tubes 4 are transported to the tea filling station, the metering tea filling equipment puts the steamed loose tea into the space formed by the tea tubes 4 and the tea brick molds 3 , place a partition 34 above the loaded loose tea, and then lock the tea brick mold 3 to press the partition 34 supported by the loose tea;

[0041] (3) One-time pressurization: the tea brick mold 3 loaded with loose tea and locked in step (2) is transported to the first tea pressing station, at this time the tea brick mold 3 is unlocked, and ...

Embodiment 2

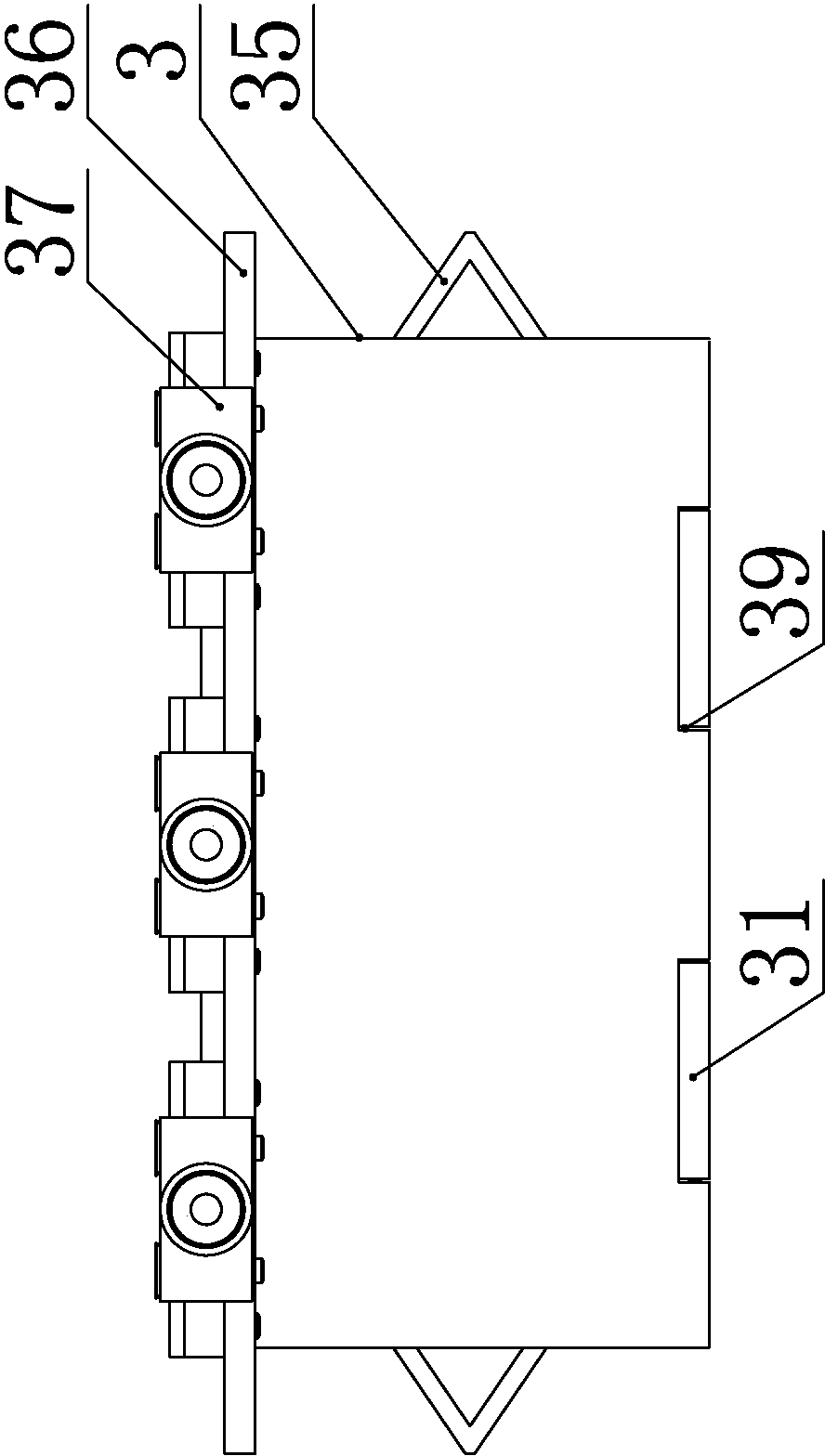

[0057] Depend on image 3 It can be seen that there are 6 mold pressure-holding locks 37 described in this embodiment, the thickness of the side wall of the box body is 2 mm, the reinforcing rib 35 is a hollow triangular prism, and the bottom of the box body is opened There are discharge holes 39 (2 in the present embodiment).

[0058] The rest are the same as embodiment 1.

Embodiment 3

[0060] Depend on figure 1 It can be seen that the thickness of the side wall of the box body described in this embodiment is 5 mm, and the number of guide rods 7 is two.

[0061] The rest are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com