Environment-friendly soybean seed coating agent and preparation method thereof

An environment-friendly, soybean-based technology, applied in botany equipment and methods, seed coating/seed dressing, biocides, etc., can solve the problems of destroying the ecological environment, accumulation of toxicity, increasing the use of fungicides, etc., and achieve environmental sanitation Pollution, low cost, and the effect of promoting production increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

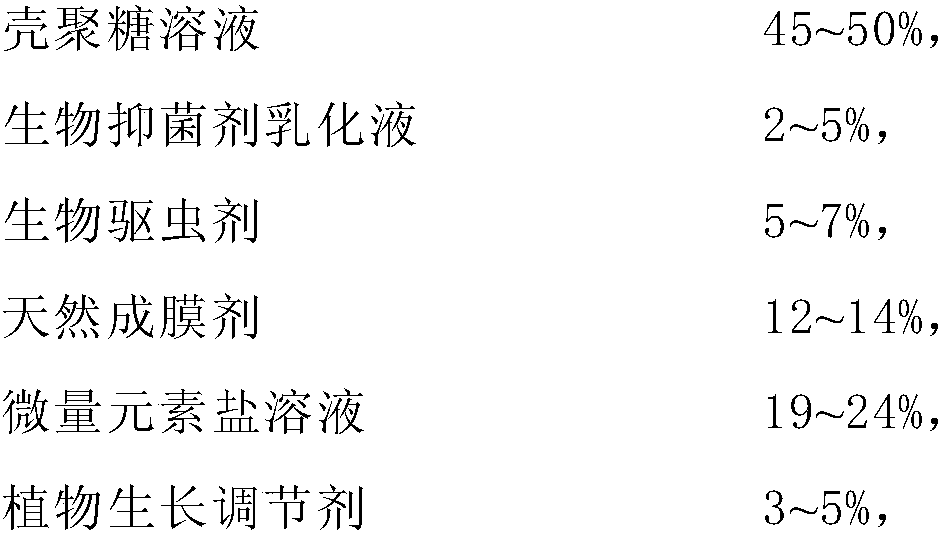

Embodiment 1

[0031] 1, dissolving chitosan in 36wt% acetic acid solution to obtain mass concentration is 5% chitosan solution 450g; Accurately take 2.5g of sucrose stearic acid monoester, add water and prepare mass concentration as 5% sucrose stearic acid monoester Lipid emulsion 50g; 0.1% azadirachtin emulsion (commercially available azadirachtin emulsion is diluted with water) 50g; 14g alginic acid is added with water to prepare 140g of alginic acid solution with a mass concentration of 10%; 0.6g ammonium bicarbonate is added with water to prepare Concentration is 60g of ammonium bicarbonate solution of 1%; 0.5g of citric acid chelated copper is added with water to prepare 50g of citric acid chelated copper solution with 1% mass concentration; 1g of citric acid chelated zinc is added with water to prepare 2% citric acid Chelated zinc solution 50g; Adding 0.8g of amino acid chelated calcium to prepare mass concentration is 40g of 2% amino acid chelated calcium solution; 1.2g of iron pyroph...

Embodiment 2

[0039]1, dissolving chitosan in 36wt% acetic acid solution to obtain mass concentration is 450g of chitosan solution of 5%; Accurately take 1.5g of sucrose stearic acid monoester, 2g of sucrose oleic acid monoester, add water to prepare mass concentration of 7 50g of biological antibacterial agent emulsion; 0.1% azadirachtin emulsion (commercially available azadirachtin emulsion is diluted with water) 50g; 7g alginic acid, 7g sodium alginate and water preparation mass concentration are 10% natural film-forming 0.8g ammonium bicarbonate is added water preparation mass concentration and is 2% ammonium bicarbonate solution 40g; 0.6g citric acid chelated copper adds water preparation mass concentration and is 1% citric acid chelated copper solution 60g; 0.6g citric acid chelate It is 30g of 2% citric acid chelated zinc solution that zinc is combined to add water preparation mass concentration; Amino acid chelated calcium 0.7g adds water preparation mass concentration and is 1% amin...

Embodiment 3

[0047] 1. Chitosan is dissolved in 36wt% acetic acid solution to obtain 500 g of chitosan solution with a mass concentration of 5%; accurately weigh 2.5 g of sucrose stearic acid monoester, 1 g of sucrose oleic acid monoester, and 1.5 g of sucrose palmitic acid monoester. g, adding water to prepare a mass concentration of 10% biological antibacterial agent emulsion 50g; 0.1% azadirachtin emulsion (commercially available azadirachtin emulsion diluted with water) 50g; 14g alginic acid, 7g sodium alginate plus water preparation quality Concentration is 140g of natural film-forming agent of 15%; 0.6g ammonium bicarbonate is added with water and is 2% ammonium bicarbonate solution 30g; 1.8g citric acid chelated copper is added with water and is 3% citric acid chelated copper Solution 60g; 0.6g citric acid chelated zinc is added with water to prepare 30g of citric acid chelated zinc solution with a mass concentration of 2%; amino acid chelated calcium 0.6g is added with water to prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com