Mine disc brake assisting device and using method thereof

A technology of disc brakes and auxiliary devices, which is applied in the direction of transmission devices, brake types, gear transmissions, etc., can solve the problems of reducing the service life of friction pairs, long braking time, and insufficient stability of braking pressure, and achieve improved stability , strong applicability and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

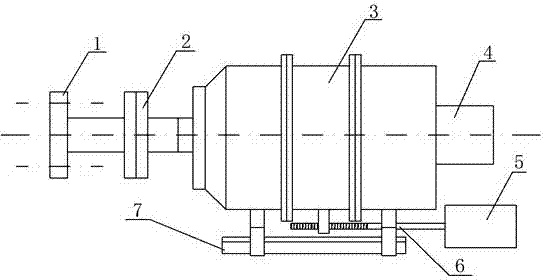

[0029] Such as Figure 1~5 As shown, the present invention provides a mining disc brake auxiliary device, including a disc shaft 1, one end of the disc shaft 1 is connected to the disc brake, and the other end is connected to the speed-up box 3 through a coupling 2, and the speed-up box 3 is in addition One end is connected to the generator 4, the bottom of the speed increasing box 3 cooperates with the ball screw 6, the ball screw 6 is connected with the motor 5, the bottom of the speed increasing box 3 is provided with a support frame 50, and the support frame 50 is arranged on the guide rail 7 to slide along the guide rail;

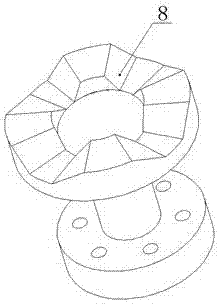

[0030] The coupling is composed of a front joint and a rear joint passing through the shaft;

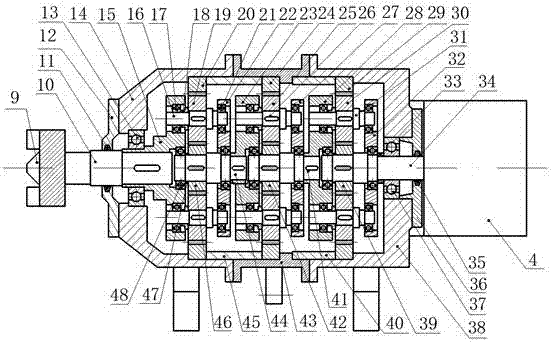

[0031] The speed-up box is a three-stage planetary transmission. At the front end of the speed-up box, a wedge-shaped sealing ring 11 is installed in the shaft end cover 12 to act as an oil seal; the power is transmitted to the planet carrier I15 through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com