Underground mold bag pile supporting method

A technology of mold pockets and grout holes, which is applied in underground chambers, earthwork drilling, wellbore lining, etc., can solve the problems of poor reinforcement effect of surrounding rock, poor strength of pile body itself, increase of disturbance of surrounding rock, etc., and reduce seepage Risk of water leakage, fast construction, and strong overall bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In the following description, the direction of the bottom of the drilled hole is taken as the front end, and the direction of the hole opening is taken as the rear end.

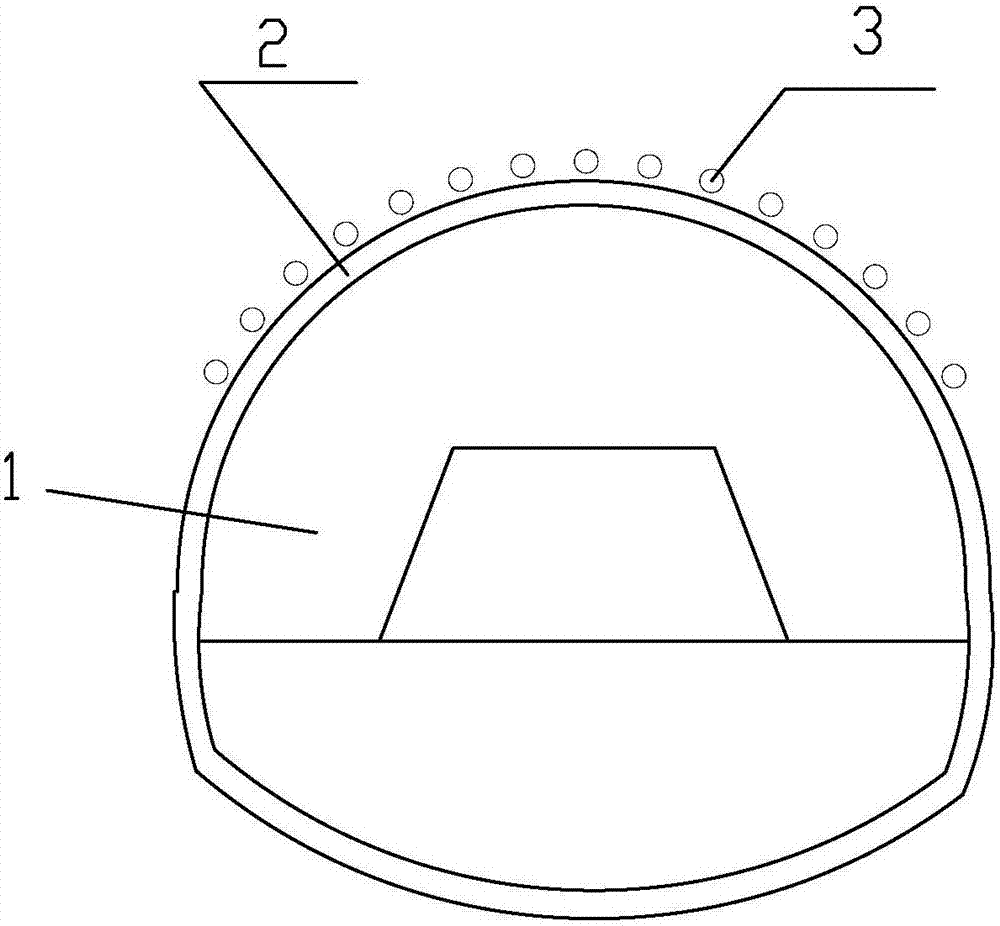

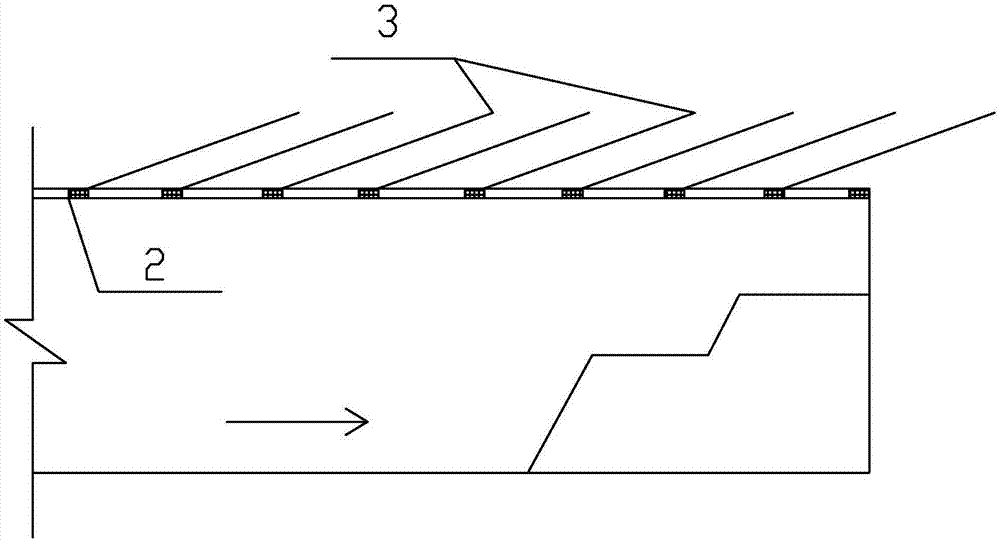

[0047] see image 3 and Figure 4 , the structure of mold bag pile unit 3 is as follows: it comprises mold bag hole 31, is provided with grouting pipe 32 in the mold bag hole 31, and the side of this grouting pipe 32 is provided with four grouting holes 35 from back to front, successively respectively The first pulp hole 351 , the second pulp hole 352 , the third pulp hole 353 and the fourth pulp hole 354 . Wherein the fourth grouting hole 354 is close to the outlet at the front end of the grouting pipe. A front divider 38 is provided at the outlet of the front end of the grouting pipe, and the outer periphery of the part of the grouting pipe with the fourth grouting hole 354 is covered with a segmented mold bag 37;

[0048] The grouting pipe covers the mold bag 34 in the middle and rear section, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com