Efficient anti-precipitation liquid composite heat stabilizer and preparation method thereof

A composite heat stabilizer and anti-precipitation technology, which is applied in the field of high-efficiency anti-separation liquid composite heat stabilizer and its preparation, can solve the problems of affecting the use effect, short storage time, poor stability, etc., saving dosage and improving compatibility. , fast absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

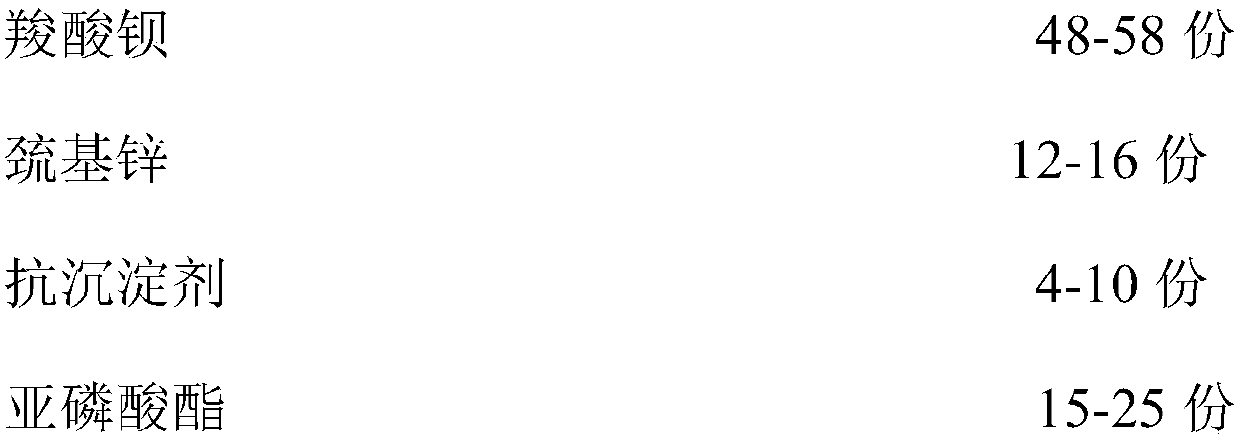

Method used

Image

Examples

Embodiment 1

[0037] The preparation of barium carboxylate: mix 200kg oleic acid, 100kg isooctanoic acid, 130kg barium hydroxide monohydrate and 5kg polyethylene glycol 400 (phase transfer catalyst), stir, slowly heat up to 100-105 ℃, react for 2 hours, reduce Press and dehydrate for 40 minutes, filter to obtain 540 kg of barium carboxylate, and the barium content is 22.8%.

Embodiment 2

[0039] Preparation of zinc mercapto: 120kg of isooctyl thioglycolate and 15kg of zinc oxide were mixed and stirred, slowly heated to 70-80°C, reacted for 3 hours, dehydrated under reduced pressure for 35 minutes, and filtered to obtain 130kg of fatty acid zinc with a zinc content of 7.12% .

Embodiment 3

[0041] A high-efficiency anti-precipitation liquid composite heat stabilizer: mix 40kg of barium carboxylate and 10kg of zinc mercapto evenly, stir, heat to 75°C, add 4kg of KH550, 2kg of KH560, heat to 85°C, add 12kg of D40 solvent, 6kg of D60 solvent , D100 solvent 6kg, butanediol methyl ether 2kg, then add phenol-free phosphite 15kg, heat preservation reaction for 30 minutes, then add 5kg tetrakis [methyl-β-(3,5-di-tert-butyl-4-hydroxybenzene Base) propionate] pentaerythritol ester, at 85 ℃ for 30 minutes, cooling, filtering, to obtain 102kg of liquid composite thermal stabilizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com