Continuous casting alloy steel bloom convex combined roller and heavy pressing process

A technology for alloy steel and bloom, which is applied in the field of continuous casting alloy steel bloom convex combined rolls and heavy reduction technology, can solve the problems of inability to improve segregation defects and high reduction efficiency, and solve the problem of matching reduction traces, The effect of improving the quality of the heart and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In Embodiment 1 and Embodiment 2, the same convex combination roller is used to carry out the pressing process in the pouring link, and the specification of the continuous casting slab: 380mm×490mm.

[0038] Example 1

[0039] Brand: 2Cr13, Sample: 3439-303

[0040] Convex combined roll reduction: 5mm+12mm;

[0041] Comparison of the reduction effect by the transverse low-magnification structure level of the continuous casting slab:

[0042] Unpressed: if Figure 4 As shown, medium pine 1.0, shrinkage cavity 2.0

[0043] Convex combined roller pressing: such as Figure 5 As shown, medium pine 0.5, shrinkage cavity 0

Embodiment 2

[0045] Brand: GCr15, Sample: 0120-101, 0120-301

[0046] Convex combined roll reduction: 6mm+15mm;

[0047] Comparison of the reduction effect by the transverse low-magnification structure level of the continuous casting slab:

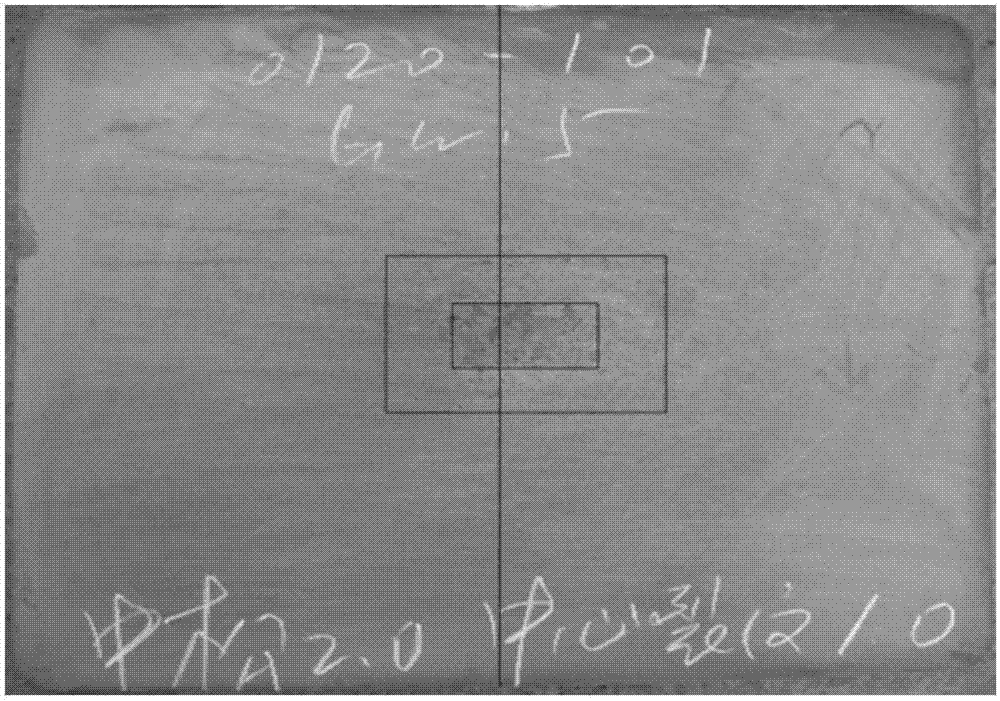

[0048] Unpressed: if Image 6 As shown, medium pine 2.0, center crack 1.0

[0049] Convex combined roller pressing: such as Figure 7 As shown, medium pine 0.5, shrinkage cavity 0

[0050] Test for carbon segregation:

[0051] Carbon segregation detection is centered on the geometric center of the slab, using a 5mm drill bit to drill steel shavings every 20mm for chemical analysis. The sampling points are as follows: Figure 8 shown. Among them, 23 points are taken in the width direction, and the center point is the 12th point; 17 points are taken in the inner and outer arc directions (the center point is still the 12th point); the midpoint of the line connecting the geometric center to the four corners (4 1 / 4 places points), a total of 43 point...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com