Sulfur-resistant methanation catalyst, preparation method and use thereof

A technology for sulfur-resistant methanation and catalyst, which can be used in physical/chemical process catalysts, chemical instruments and methods, and hydrocarbon production from carbon oxides. It can solve the problems of low CO conversion rate and poor selectivity, and achieve good technical results. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

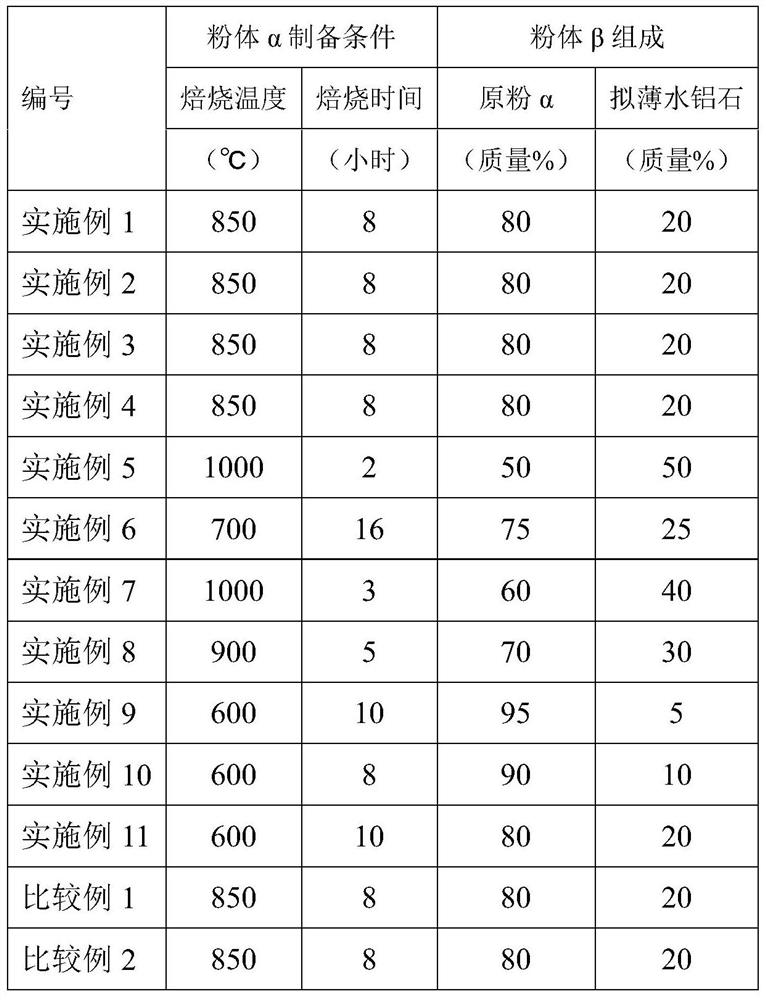

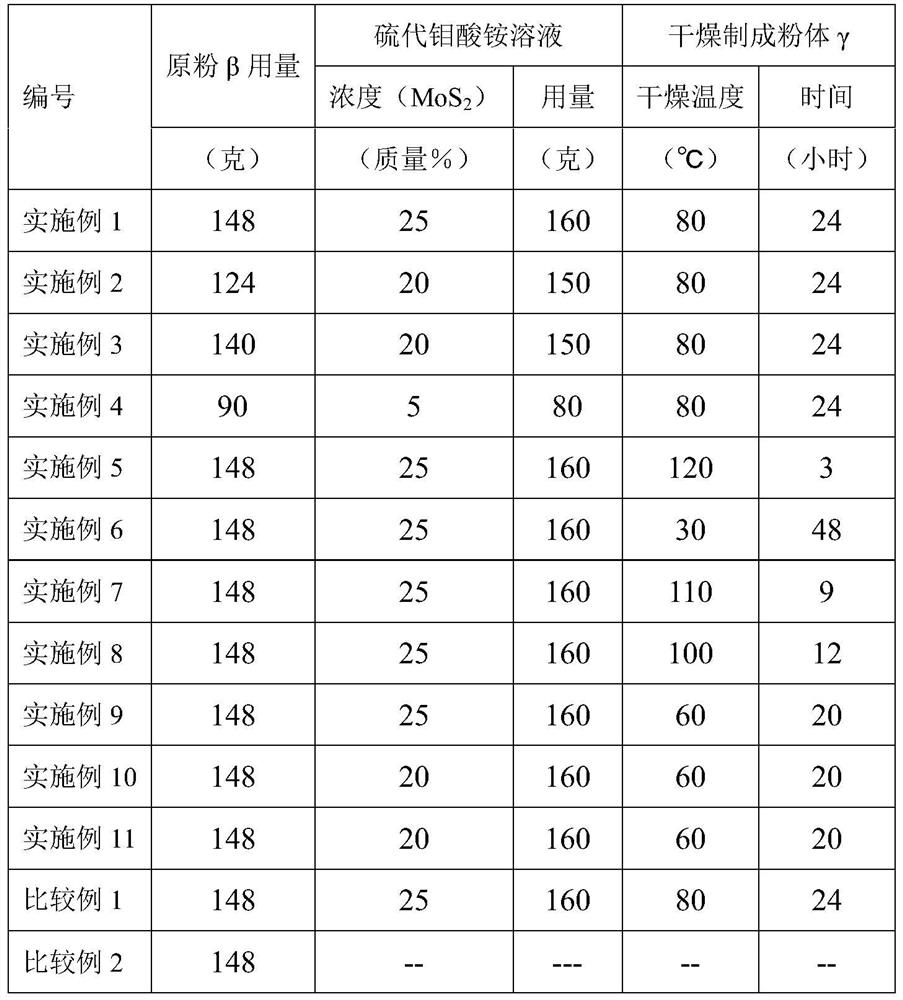

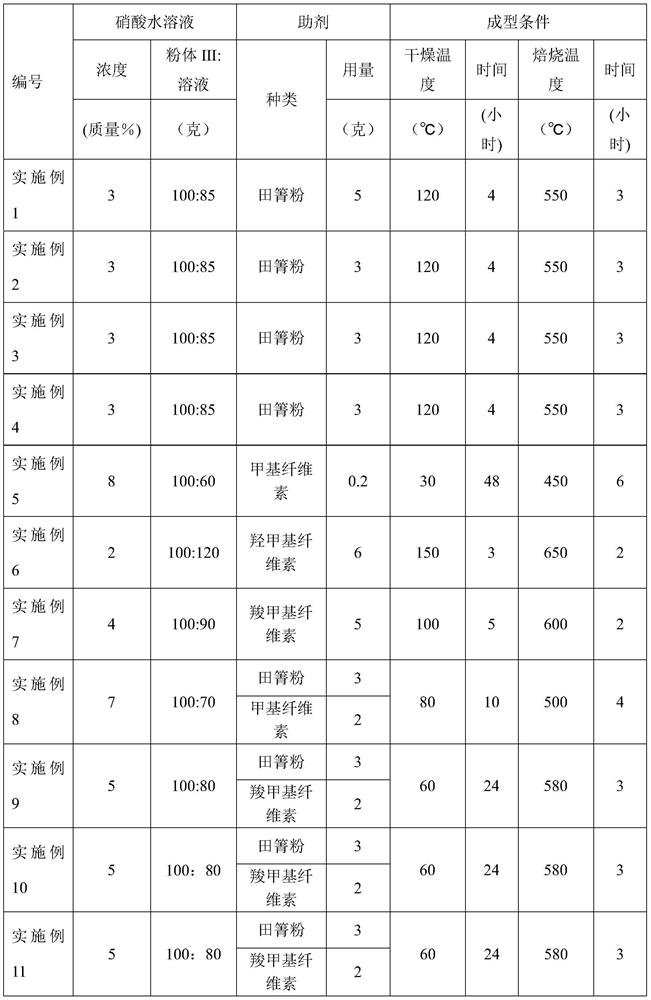

[0060] Weigh 300 grams of the original pseudo-boehmite powder and roast at 850°C for 8 hours to obtain powder α; weigh 160 grams of the above-mentioned powder α and pseudo-boehmite powder by mass percentage and mix them at 80:20 to obtain powder Body β; Weigh 148 grams of powder β, add MoS 2 It is mixed with 160 grams of 25.0% ammonium thiomolybdate solution, then dried at 80 ° C for 24 hours for dehydration, and re-made into powder γ; the above powder γ and the aqueous solution containing 3% nitric acid by mass percentage are 100 by mass. : 85, adding 5 grams of Tianqing powder, kneading and extruding, drying at 120°C for 4 hours and calcining at 550°C for 3 hours to obtain catalyst precursor I; Weigh 94 grams of catalyst precursor I and Ni 3 P is 4% nickel hypophosphite and Fe by mass 3 P is 2% ferric hypophosphite and 100 grams of ammonium hypophosphite acid aqueous solution for impregnation, wherein the molar ratio of nickel hypophosphite and ammonium hypophosphite in the...

Embodiment 2

[0068] Weigh 300 grams of the original pseudo-boehmite powder and roast at 850°C for 8 hours to obtain powder α; weigh 160 grams of the above-mentioned powder α and pseudo-boehmite powder by mass percentage and mix them at 80:20 to obtain powder Body β; Weigh 124 grams of powder β, add MoS 2 It is mixed with 150 grams of 20.0% ammonium thiomolybdate solution, then dried at 80 ° C for 24 hours and dehydrated, and re-made into powder γ; the above powder γ and the aqueous solution containing 3% nitric acid by mass percentage are 100 by mass. : 85, adding 3 grams of Tianqing powder, kneading and extruding, drying at 120°C for 4 hours and calcining at 550°C for 3 hours to obtain catalyst precursor I; Weigh 92 grams of catalyst precursor I and Ni 3 P is 4.5% nickel hypophosphite and Fe by mass 3 P is 3% ferric hypophosphite and 100 grams of ammonium hypophosphite acid aqueous solution for impregnation, wherein the molar ratio of nickel hypophosphite and ammonium hypophosphite in th...

Embodiment 3

[0075] Weigh 300 grams of the original pseudo-boehmite powder and roast at 850°C for 8 hours to obtain powder α; weigh 160 grams of the above-mentioned powder α and pseudo-boehmite powder by mass percentage and mix them at 80:20 to obtain powder Body β; Weigh 140 grams of powder β, add MoS 2 It is mixed with 150 grams of 20.0% ammonium thiomolybdate solution, then dried at 80 ° C for 24 hours and dehydrated, and re-made into powder γ; the above powder γ and the aqueous solution containing 3% nitric acid by mass percentage are 100 by mass. : 85, adding 3 grams of Tianqing powder, kneading and extruding, drying at 120°C for 4 hours and calcining at 550°C for 3 hours to obtain catalyst precursor I; Weigh 100 grams of catalyst precursor I and Ni 3 P is 0.1% nickel hypophosphite and Fe by mass 3 P is 100 grams of 0.5% ferric hypophosphite and ammonium hypophosphite acid aqueous solution for impregnation, wherein the molar ratio of nickel hypophosphite and ammonium hypophosphite in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com