Treatment of exhaust gases from cement clinker production

A technology of cement clinker and exhaust gas counterflow, applied in gas treatment, membrane technology, dispersed particle separation, etc., can solve the problem of not completely solving the problem of purifying exhaust gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

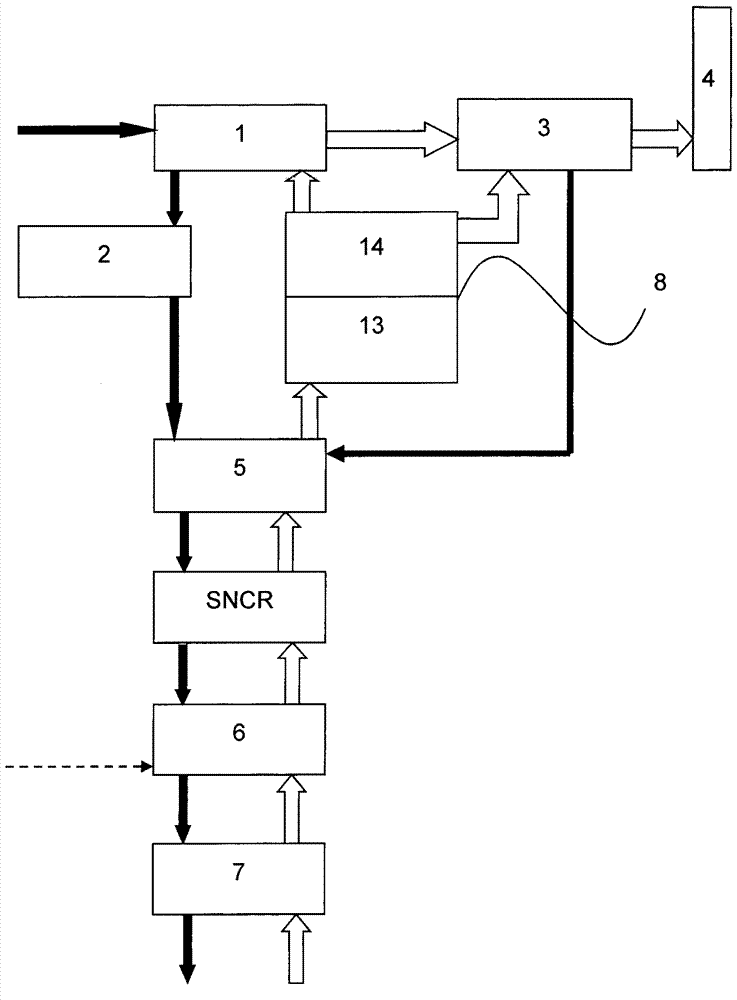

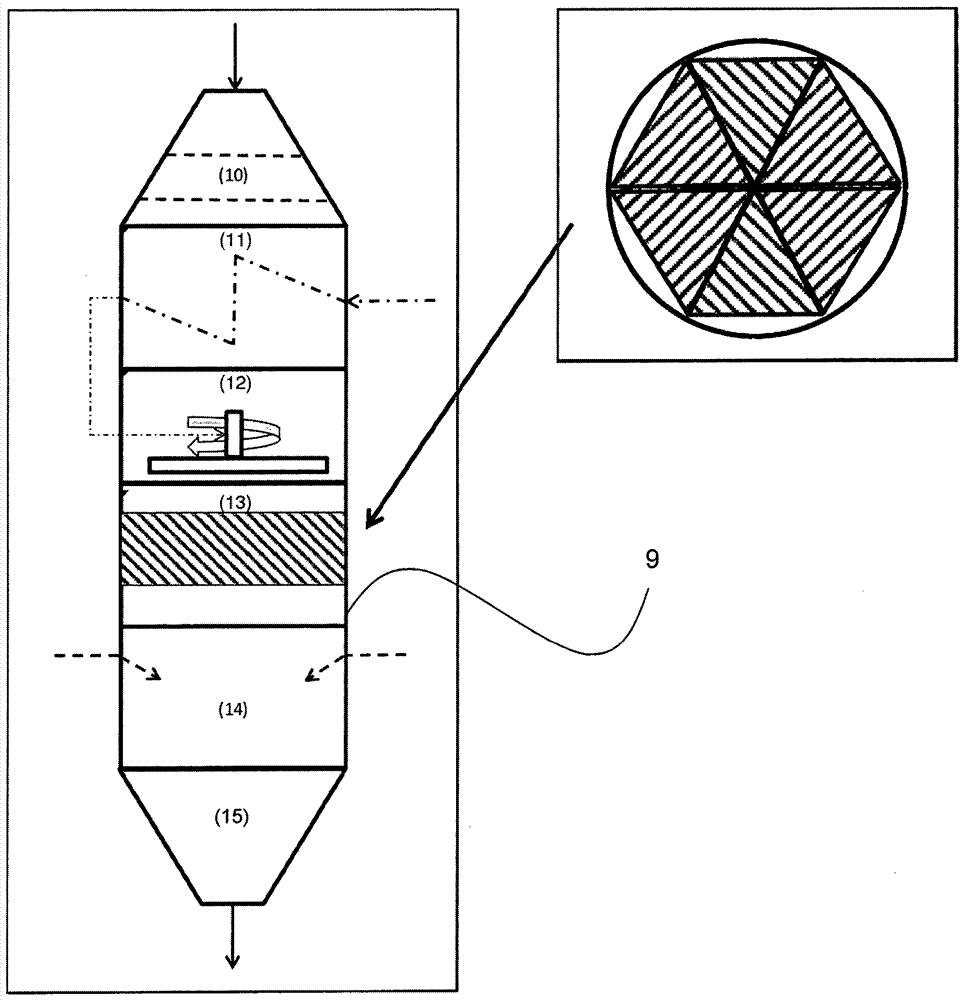

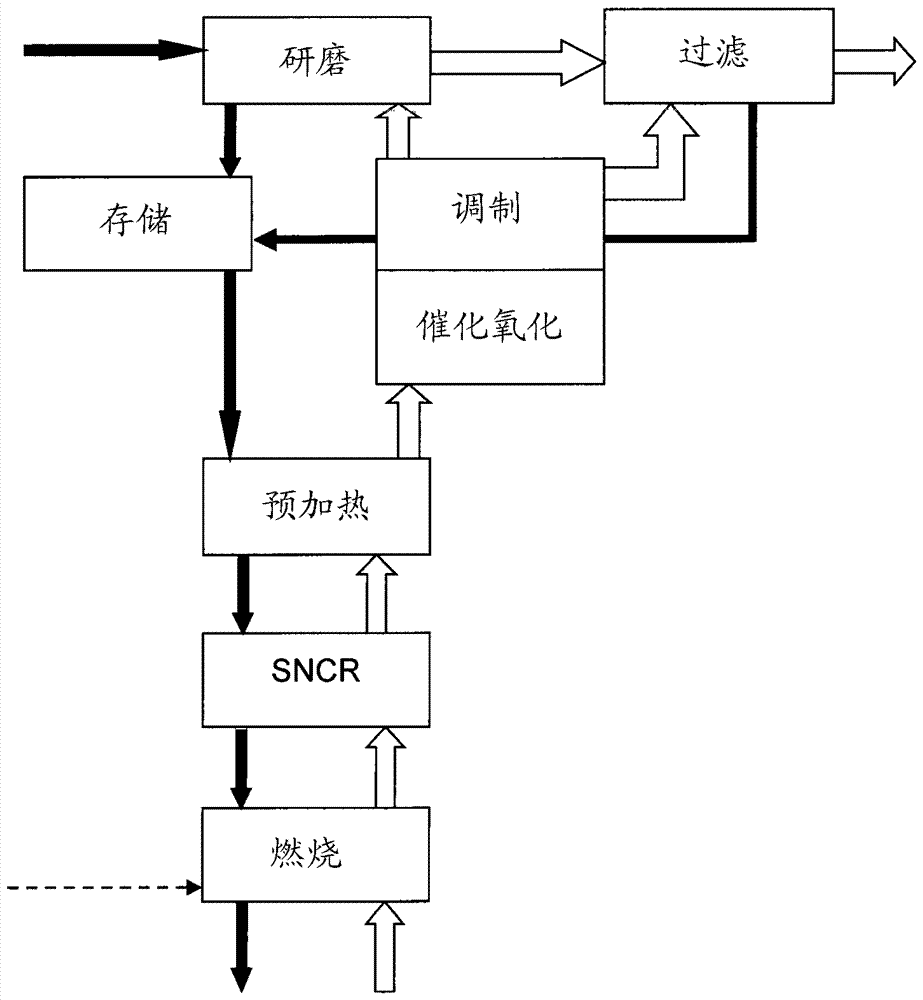

[0042] figure 1 The method steps are shown. Solid material flow is shown by solid arrows and gas flow by hollow arrows. The raw materials are ground in a mill in a known manner. The raw meal produced is fed to a preheating step, where in the raw meal silo, a storage step is usually in between. Preheating may include precalcination. The preheated and optionally precalcined raw meal is supplied to a rotary kiln where it is burned to form cement clinker. Subsequent steps of cooling, grinding, etc. are not shown. Fuel is supplied (dashed arrow) and burned to burn raw meal in the kiln. Nitrogen oxides are produced here and in the entire thermal area of the kiln from oxygen and nitrogen. In the kiln, air flows counter-currently to the raw meal so that hot exhaust gases containing nitrogen oxides and other pollutants leave the kiln at the point where the raw meal is fed. From there it is directed towards a pre-heating step where the reagents for SNCR are mixed according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com