Method and device for electromagnetic enhanced wood fiber liquefying-jet rotational flow multi-level energy conversion

A technology of wood fiber and electromagnetic strengthening, which is applied in biochemical cleaning devices, biochemical equipment and methods, methods for stress-stimulated microbial growth, etc., can solve problems such as low degradation rate and easy crusting of fermentation tanks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

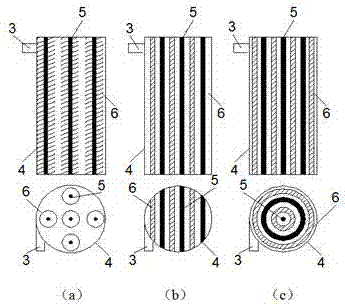

Image

Examples

Embodiment 1

[0058] The treatment object of this embodiment: domestic sewage of a city sewage treatment plant, its COD is 300-400mg / L, BOD is 200mg / L, ammonia nitrogen is 30mg / L, total phosphorus is 2-3mg / L, cellulose, hemifiber The content of lignin and lignin is 30%.

[0059] The anaerobic fermentation process of domestic sewage in this embodiment is carried out independently in stages, specifically including the following three stages:

[0060] (1) Pretreatment and hydrolysis section: the pre-purchased and cultivated composite strain MC1 is divided into 5×10 9 The inoculum amount of cfu / mL is evenly mixed with the raw materials, and the pH of the mixture is adjusted to 5 by acetic acid, and the mixture is sent tangentially into the hydrolysis tank at 6m / s to form a stable swirl in the tank. Under the action of 0.8V and a magnetic field strength of 0.5T, carry out hydrolysis treatment for 24 hours to strengthen the degradation of cellulose, hemicellulose and lignin in the raw materials;...

Embodiment 2

[0071] The treatment object of this embodiment: the dairy cow manure filtrate produced by a certain dairy farming factory, its COD is 40000~50000mg / L, BOD is 20000-30000mg / L, ammonia nitrogen 40mg / L, cellulose, hemicellulose and lignin content are 70%; cow manure filtrate passed through 80 mesh sieve;

[0072] The anaerobic fermentation process of domestic sewage in this embodiment is carried out independently in stages, specifically including the following three stages:

[0073] (1) Pretreatment hydrolysis section: Mix the pre-purchased and cultivated Phanerochaete chrysosporium and Penicillium rugosa in a mass ratio of 6:4, and mix them with 6.5×10 9 The inoculation density of cfu / mL is uniformly mixed with the raw materials, the pH of the mixture is adjusted to 4 by citric acid, and the mixture is sent tangentially into the hydrolysis tank at 8m / s to form a stable swirl in the tank. Under the action of 1V and a magnetic field strength of 5T, carry out hydrolysis treatment ...

Embodiment 3

[0079] The processing object of this embodiment: waste vegetables in a certain vegetable cultivation base, its COD is 50000mg / L, BOD is 30000mg / L, and the content of cellulose, hemicellulose and lignin is 80%;

[0080] The anaerobic fermentation process of domestic sewage in this embodiment is carried out independently in stages, specifically including the following three stages:

[0081] (1) Pretreatment and hydrolysis section: the pre-purchased and cultivated compound strain WSC-6 according to 4×10 9 The inoculum amount of cfu / mL is evenly mixed with the raw materials, the pH of the mixture is adjusted to 5.1 by citric acid, and the mixture is sent tangentially into the hydrolysis tank at 10m / s to form a stable swirl in the tank. Under the action of 1.5V and a magnetic field strength of 9T, carry out hydrolysis treatment for 20 hours to strengthen the degradation of cellulose, hemicellulose and lignin in the raw materials; after the hydrolysis is completed, pass high-tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com