Small output volume automobile engine chain timing system

A technology of automobile engine and timing system, applied in the direction of engine components, machine/engine, belt/chain/gear, etc., can solve the problems of increased system vibration, large friction loss of timing system, loss of tensioning effect, etc. Smooth and quiet movement, reducing system friction loss, reducing the effect of engine vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

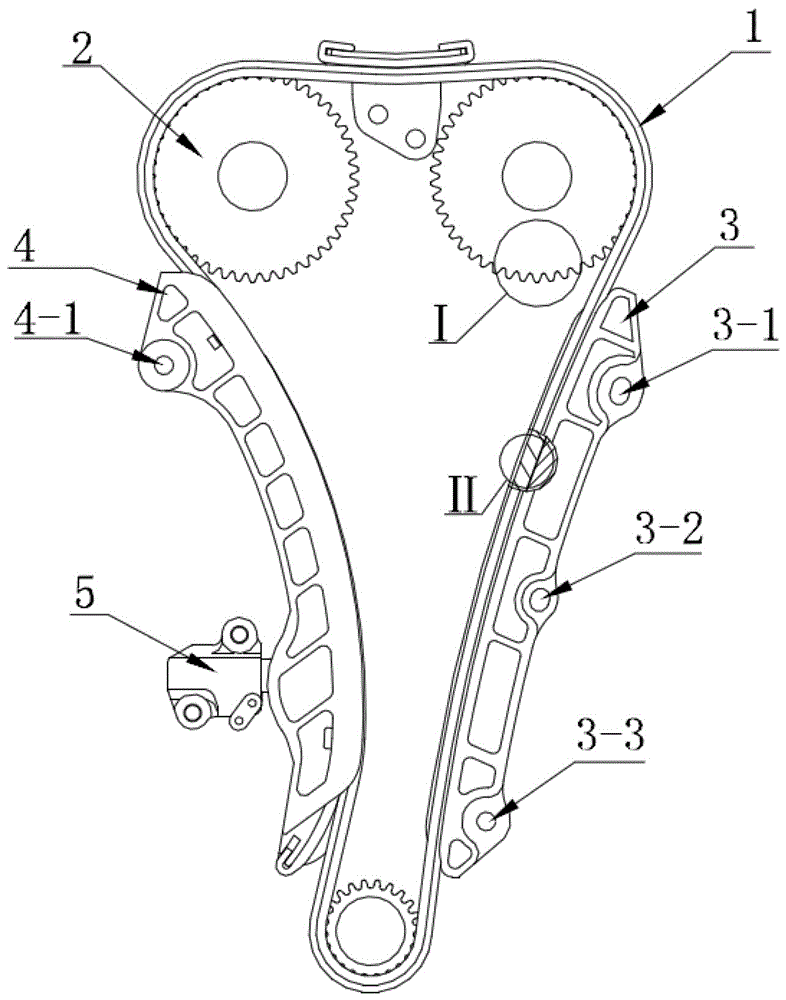

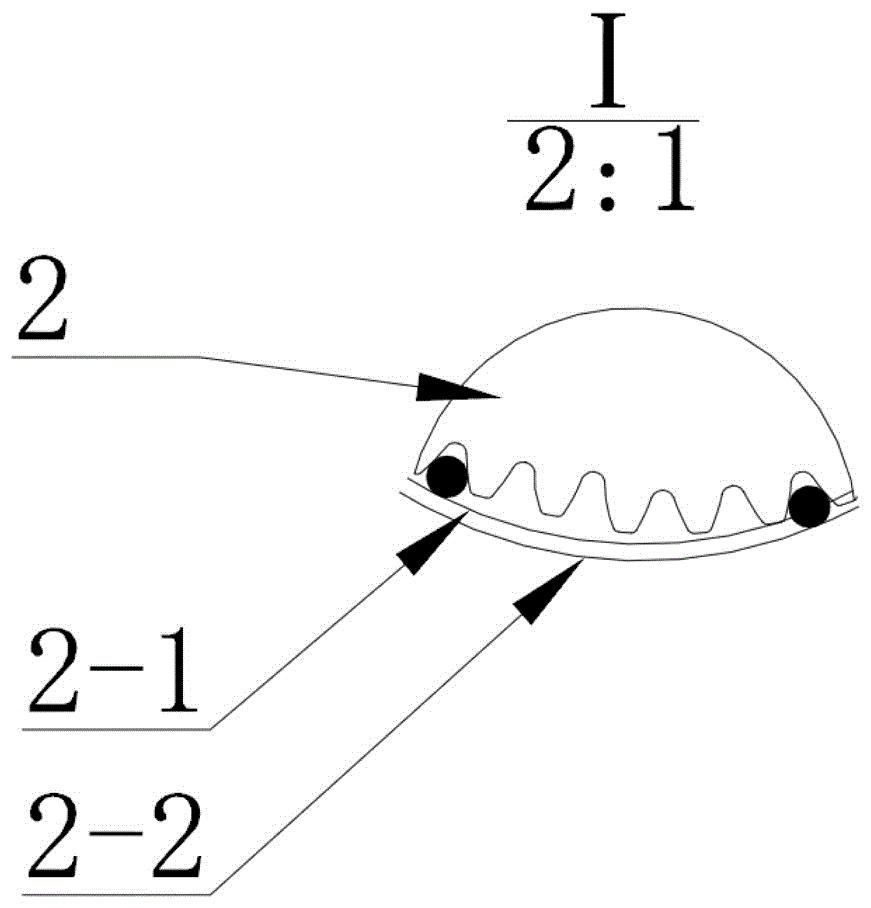

[0014] like Figure 1-4 As shown, the present invention relates to a chain timing system for a small-displacement automobile engine, comprising a chain 1, a sprocket 2, a guide rail 3, a tensioning arm 4, and a tensioner 5 assembled together in sequence, and its technical points are: The chain is a short joint poly precision transmission toothed chain. The material of the sprocket is high-strength nylon. The pitch circle radius of the sprocket changes with the circumferential position of the sprocket. order, magnitude and phase to eliminate specific chain drive resonance orders for more efficient system design;

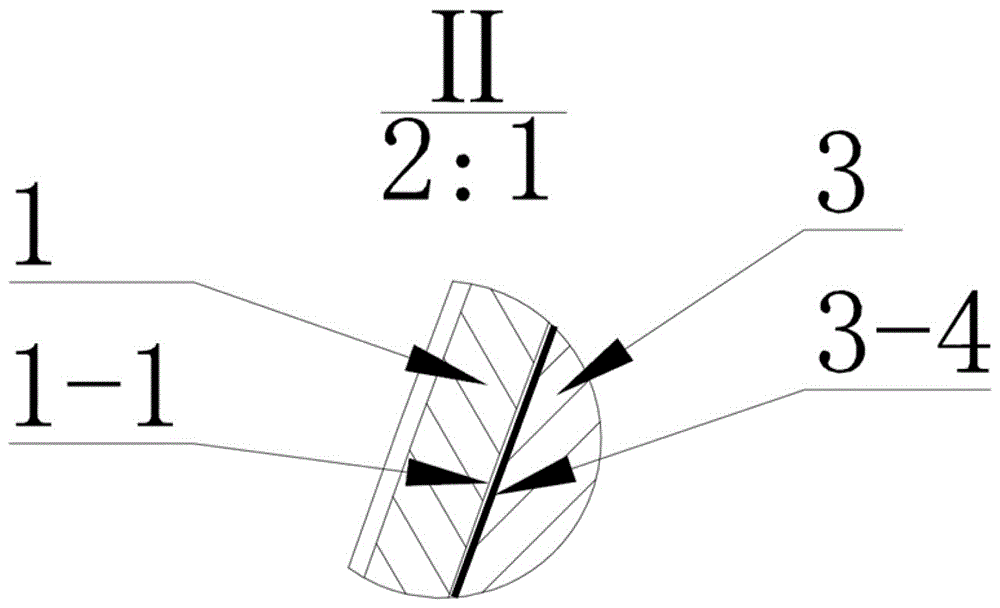

[0015] The guide rail surface of the tension arm 4 of the guide rail 3 is provided with a friction surface anti-friction layer 3-4, and the chain 1 is in contact with the friction surface anti-friction layer 3-4;

[0016] The guide rail 3 and the tension arm 4 are installed through the positioning pin hole 3-1 on the first guide rail, the positioning pin hole 3-2 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com