Paint for automobile thermoplastic plastic parts as well as preparation method and application of paint

A technology for thermoplastics and accessories, applied in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of fading of the wheel hub surface of economical cars, few reports on industrialization, and expensive metallic paint, etc. The effect of industrialized mass production, excellent adhesion, excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

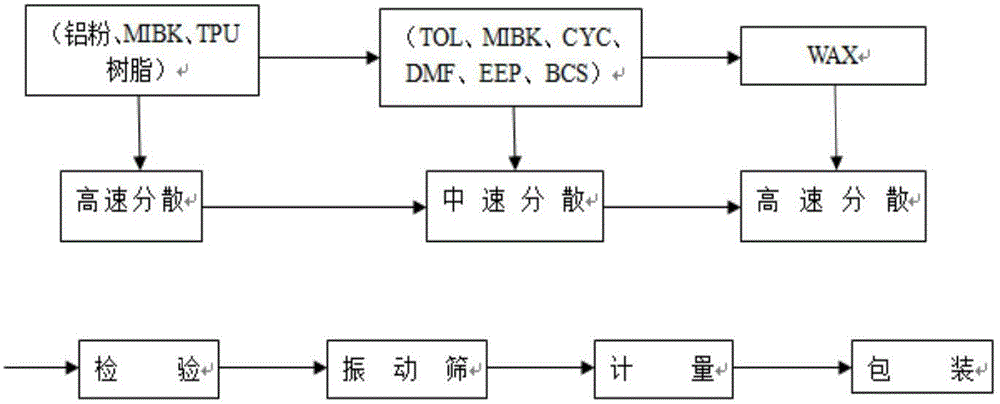

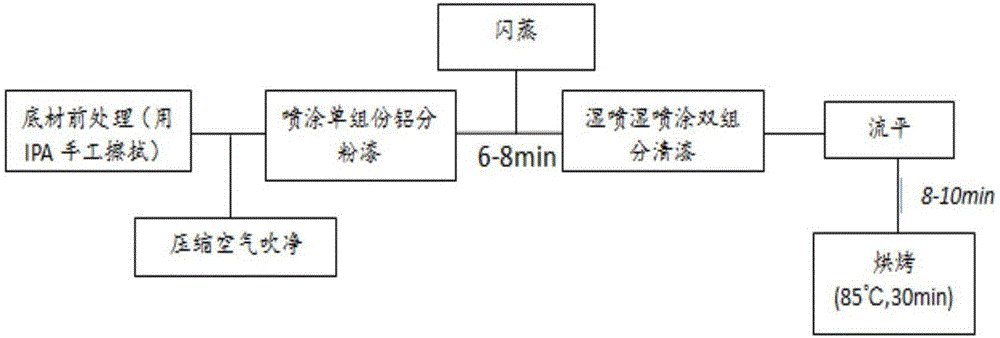

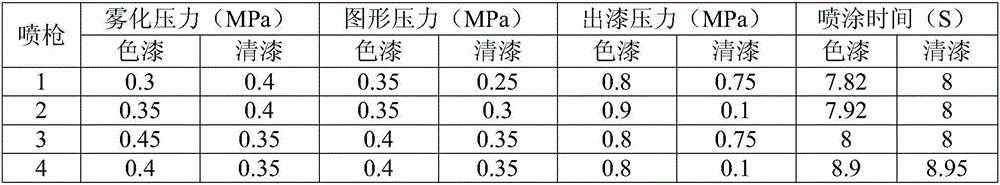

Method used

Image

Examples

Embodiment 1

[0041] A coating for automotive thermoplastic parts of the present invention is a two-component varnish composed of raw materials and diluents, comprising the following components by weight:

[0042] 8 parts of aluminum powder 8801; produced by Shanghai Yile Chemical Co., Ltd.;

[0043] 9 parts of methyl isobutyl ketone (MIBK); produced by Shandong Zixiang Chemical Co., Ltd.;

[0044] 60 parts of elastic polyurethane resin (TPU); Produced by Tianchang Xingtai Fine Chemical Factory;

[0045] 8 parts of wax; produced by Shanghai Gerunning Chemical Technology Co., Ltd.;

[0046] Thinner 15 parts.

[0047] Wherein, the diluent comprises the following components by weight:

[0048] 10 parts of toluene (TOL); produced by Changzhou Zhongao Chemical Co., Ltd.;

[0049] 58 parts of methyl isobutyl ketone (MIBK); produced by Shandong Zixiang Chemical Co., Ltd.;

[0050] 15 parts of cyclohexanone (CYC); produced by Changzhou Zhongao Chemical Co., Ltd.;

[0051] 8 parts of N-N-dimet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com