A kind of spinel fiber reinforced zirconia refractory material and preparation process thereof

A refractory material and preparation technology, applied in the field of refractory materials, can solve problems such as short service life, severe cracking, and easy cracks, and achieve the effects of improved service life, high thermal shock resistance, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

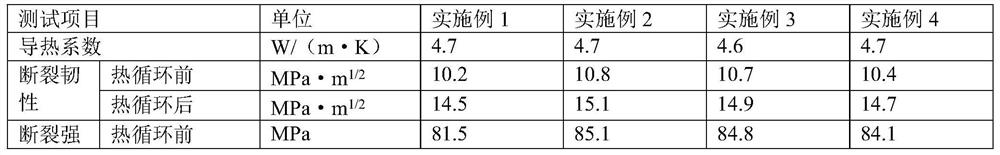

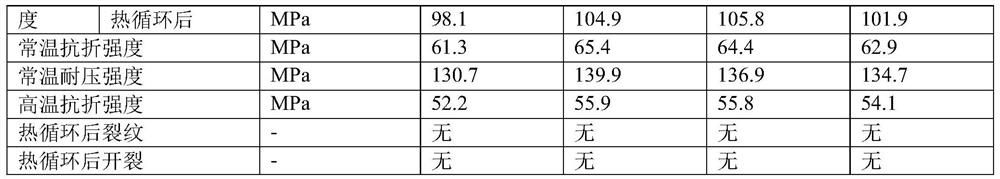

Examples

Embodiment 1

[0037] A preparation process of a spinel fiber reinforced zirconia refractory material, the preparation steps of the refractory material are as follows:

[0038] 1) Preparation of rare earth-doped magnesia partially stabilized zirconia micropowder: a) After mixing the monoclinic zirconia, fused magnesia fine powder, high alumina bauxite micropowder, praseodymium nitrate and lanthanum nitrate through wet ball milling Dry at 100°C for 40 minutes to obtain the precursor powder;

[0039] b) The precursor powder obtained in a) is placed at 750°C for 230 minutes, and air-cooled to obtain a doped powder;

[0040] c) Soak the doped powder obtained in b) for 3 minutes in distilled water, filter the powder with filter paper, dry the powder at 100°C for 40 minutes, and pass through a 200-mesh sieve to obtain the rare earth-doped magnesium oxide part Stabilized zirconia powder;

[0041] 2) Mix the rare earth-doped magnesia partially stabilized zirconia micropowder obtained in 1) with dead...

Embodiment 2

[0046] A preparation process of a spinel fiber reinforced zirconia refractory material, the preparation steps of the refractory material are as follows:

[0047] 1) Preparation of rare earth-doped magnesia partially stabilized zirconia micropowder: a) After mixing the monoclinic zirconia, fused magnesia fine powder, high alumina bauxite micropowder, praseodymium nitrate and lanthanum nitrate through wet ball milling Dry at 110°C for 50 minutes to obtain the precursor powder;

[0048] b) The precursor powder obtained in a) is placed at 770°C for 250 minutes, and air cooled to obtain a doped powder;

[0049] c) Soak the doped powder obtained in b) in distilled water for 5 minutes, filter the powder with filter paper, dry the powder at 110°C for 50 minutes, and pass through a 200-mesh sieve to obtain the rare earth-doped magnesium oxide part Stabilized zirconia powder;

[0050] 2) Mix the rare earth-doped magnesia partially stabilized zirconia micropowder obtained in 1) with de...

Embodiment 3

[0055] A preparation process of a spinel fiber reinforced zirconia refractory material, the preparation steps of the refractory material are as follows:

[0056] 1) Preparation of rare earth-doped magnesia partially stabilized zirconia micropowder: a) After mixing the monoclinic zirconia, fused magnesia fine powder, high alumina bauxite micropowder, praseodymium nitrate and lanthanum nitrate through wet ball milling Dry at 110°C for 45 minutes to obtain the precursor powder;

[0057] b) The precursor powder obtained in a) is placed at 750°C for 240 minutes, and air-cooled to obtain a doped powder;

[0058] c) Soak the doped powder obtained in b) in distilled water for 5 minutes, filter the powder with filter paper, dry the powder at 110°C for 45 minutes, and pass through a 200-mesh sieve to obtain the rare earth-doped magnesium oxide part Stabilized zirconia powder;

[0059] 2) Mix the rare earth-doped magnesia partially stabilized zirconia micropowder obtained in 1) with de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com