Method for preparing active porous nano-cerium dioxide based on inorganic template

A nano-ceria, inorganic template technology, applied in inorganic chemistry, chemical instruments and methods, rare earth metal oxides/hydroxides, etc., can solve problems such as limiting the development of ceria, harsh reaction conditions, and uneven size , to achieve the effects of good peroxidase activity, low preparation cost and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) Add 0.5g Ce(NO 3 ) 3 •6H 2 O and 2.5 g NH 4 HCO 3 were added to 30mL and 15mL of deionized water, stirred for 2min to dissolve, and Ce(NO 3 ) 3 solution and NH 4 HCO 3 solution;

[0018] (2) Use CH 3 COOH NH 4 HCO 3 The pH of the solution was adjusted to 6.5, and then it was added to Ce(NO 3 ) 3 In the solution, continue to stir for 1 min after the addition, then seal the system and place it in an environment of 6°C to react for 6 h;

[0019] (3) Centrifuge after the reaction is complete, wash the resulting white product with deionized water and ethanol solution several times, and then dry it in air at 60°C for 12 hours;

[0020] (4) Calcinate the dried product in air at 450°C for 1.5h to obtain porous CeO 2 nanoparticles.

Embodiment 2

[0022] (1) Add 0.5g Ce(NO 3 ) 3 •6H 2 O and 2.5 g NH 4 HCO 3 were added to 30mL and 15mL of deionized water, stirred for 2min to dissolve, and Ce(NO 3 ) 3 solution and NH 4 HCO 3 solution;

[0023] (2) Use CH 3 COOH NH 4 HCO 3 The pH of the solution was adjusted to 7.0, and then it was added to Ce(NO 3 ) 3 In the solution, continue to stir for 1 min after the addition, then seal the system and place it in an environment of 6°C to react for 6 h;

[0024] (3) Centrifuge after the reaction is complete, wash the resulting white product with deionized water and ethanol solution several times, and then dry it in air at 60°C for 12 hours;

[0025] (4) Calcinate the dried product in air at 450°C for 1.5h to obtain porous CeO 2 nanoparticles.

Embodiment 3

[0027] (1) Add 0.5g Ce(NO 3 ) 3 •6H 2 O and 2.5 g NH 4 HCO 3 were added to 30mL and 15mL of deionized water, stirred for 2min to dissolve, and Ce(NO 3 ) 3 solution and NH 4 HCO 3 solution;

[0028] (2) Use CH 3 COOH NH 4 HCO 3 The pH of the solution was adjusted to 7.5, and then it was added to Ce(NO 3 ) 3 In the solution, continue to stir for 1 min after the addition, then seal the system and place it in an environment of 6°C to react for 6 h;

[0029] (3) Centrifuge after the reaction is complete, wash the resulting white product with deionized water and ethanol solution several times, and then dry it in air at 60°C for 12 hours;

[0030] (4) Calcinate the dried product in air at 450°C for 1.5h to obtain porous CeO 2 nanoparticles.

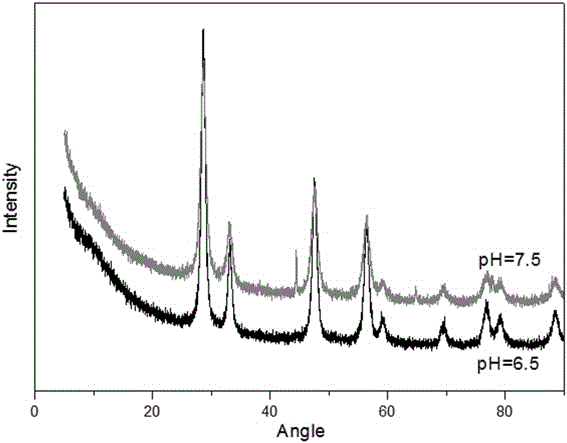

[0031] figure 1 For the prepared CeO of embodiment 1 and embodiment 3 2 XRD diffraction pattern of nanoparticles.

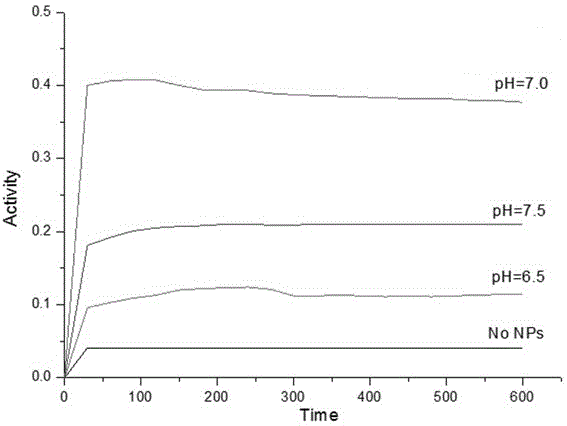

[0032] With the CeO prepared by embodiment 1-3 2 The nanoparticles were dissolved in water respectively, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com