Method for manufacturing power machine driven by Ampere force and electrostatic force

A technology of power machine and electrostatic force, which is applied in the field of physical experiment instruments, can solve the problems of lack of effective realization of electrostatic force and ampere force to drive the power machine together, and achieve the effect of reducing eddy current effect, easy contact, and reducing air resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

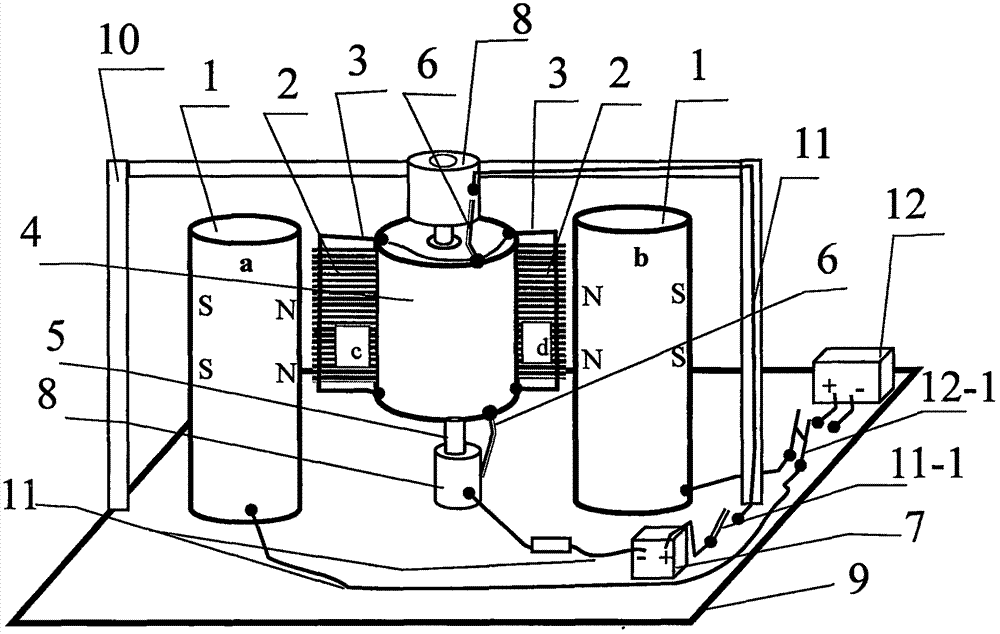

[0016] Taking the high-voltage electrode column N=2 as an example as a further specific implementation description

[0017] as attached figure 1 : A method for making ampere force and electrostatic force driven power machine, mainly composed of high voltage electrode column 1, rotating plate 2, ampere force wire 3, plastic cylinder 4, plastic cylinder shaft 5, electric brush 6, ampere force power supply 7, electrode column 8. Composed of high-density insulating board 9, insulating bracket 10, connecting wire 11, amperometric power switch 11-1, high-voltage electrostatic power supply 12, and high-voltage electrostatic power switch 12-1, the feature is that the rotating plate 2 includes a comb-shaped conductor plate c and the comb-shaped conductor plate d are fixed on the busbar of the plastic cylinder 4 (insulating plastic) by a row of copper wires of non-ferromagnetic conductors (the tip facing outward) with one end as the tip, and the plastic cylinder is vertical in the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com