Preheating furnace

A preheating furnace and furnace body technology, applied in the direction of preheating costs, furnaces, furnace components, etc., can solve the problems of uneven feeding of raw materials into the furnace, harsh requirements for raw materials, and low quality castings, and achieve good environmental protection effects, uniform distribution, Uniform effect in the furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

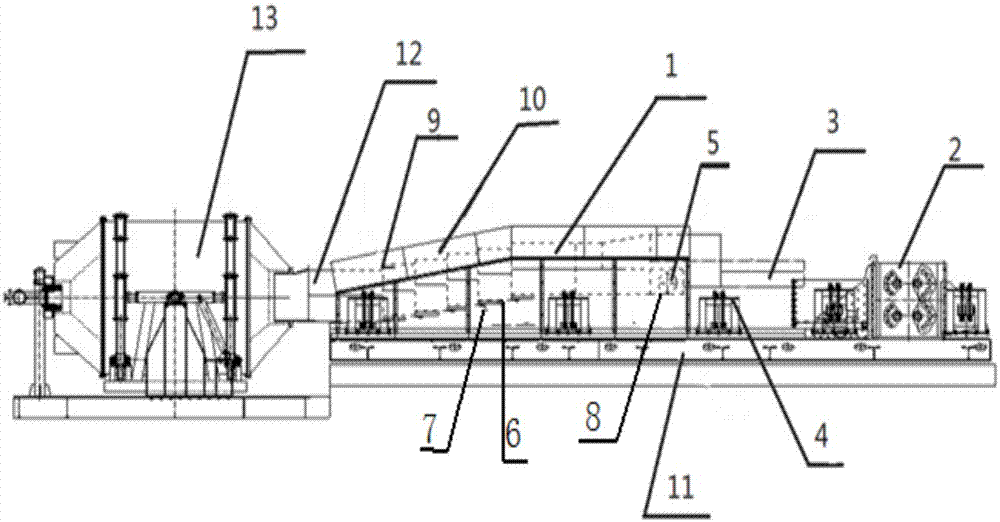

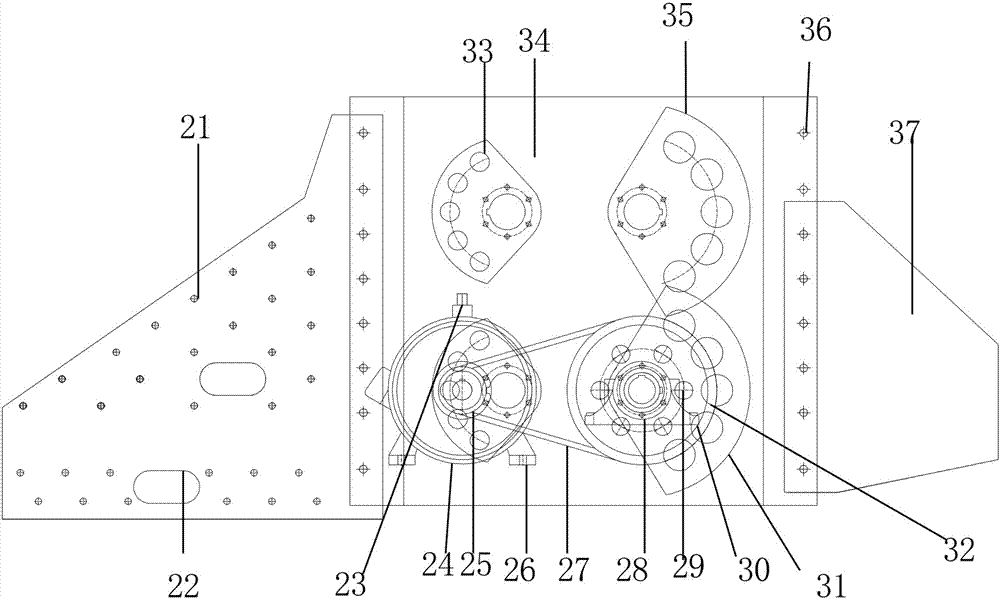

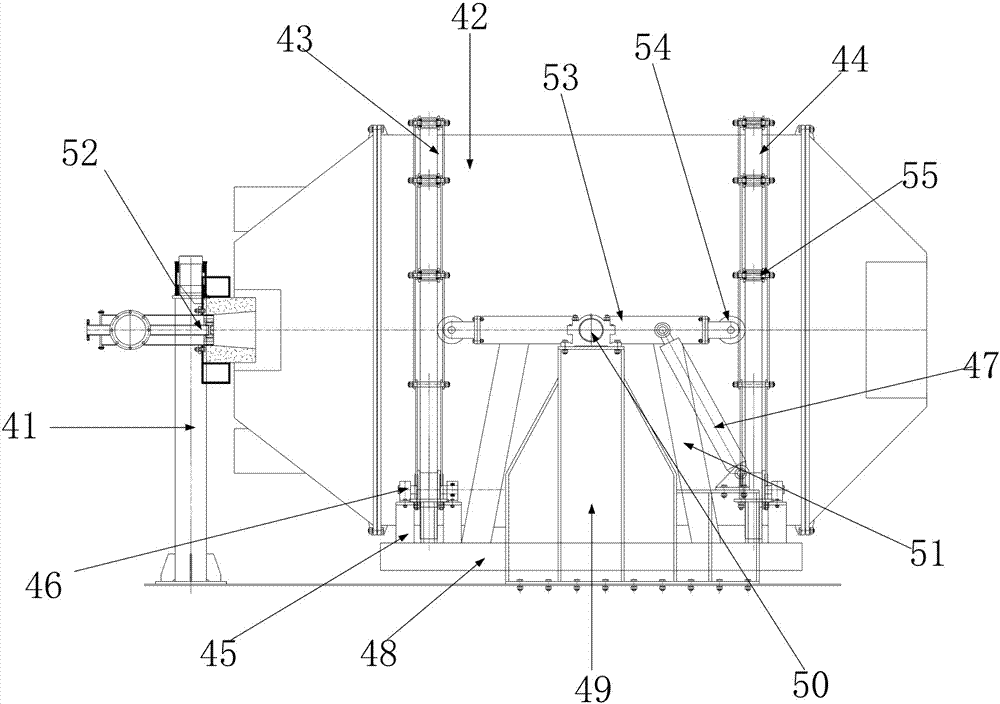

[0024] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0025] Such as Figure 1 to Figure 3 As shown, the preheating furnace of the present invention includes a stepped furnace body 1 of the preheating furnace, an exciter conveying device 2, a feeding port 3, a swinging support column 4, an air induction outlet 5, a split preheating burner 6, an automatic ignition Device 7, flue gas temperature sensor 8, front-end temperature sensor 9, furnace body protective cover 10, furnace body load-bearing beam 11, discharge port 12, natural gas rotary furnace 13, preheating furnace stepped furnace body 1 located in furnace body protective cover 10 Between the bearing beam 11 and the furnace body, the smoke temperature sensor 8 is located on the side of the induced air outlet 5, the split type preheating burner 6 is located on the side of the automatic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com