A heating furnace for heat treatment of wear-resistant parts

A technology for heating furnaces and wear-resistant parts, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of reducing the quality of wear-resistant parts, temperature imbalance, and inability to effectively eliminate stress, so as to reduce friction and improve efficiency , Guarantee the effect of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

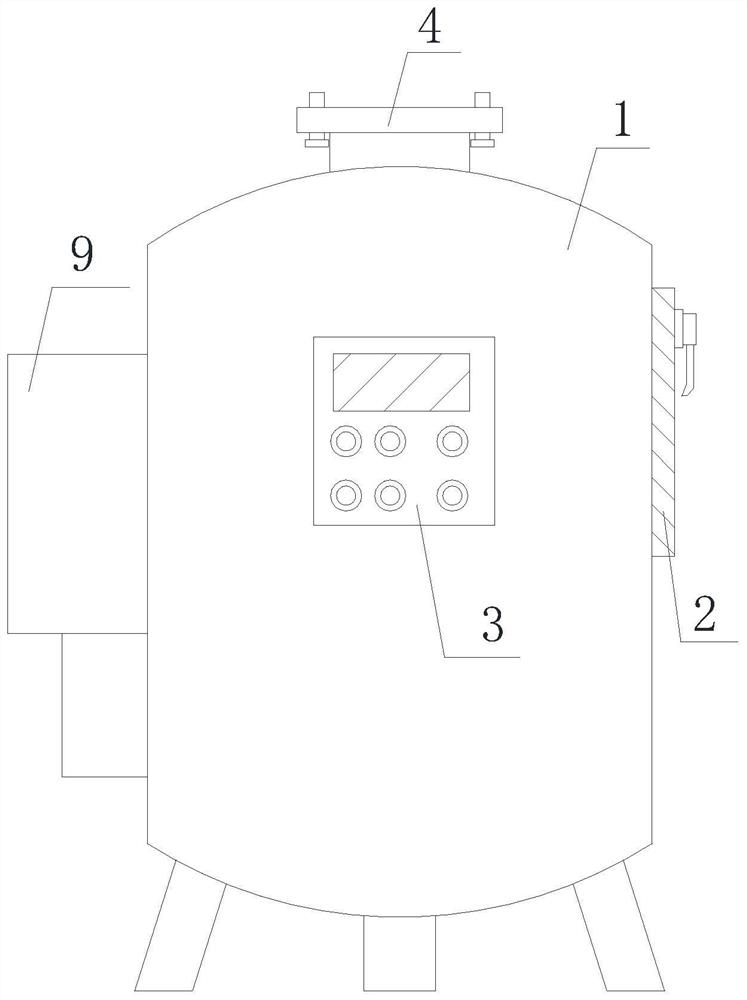

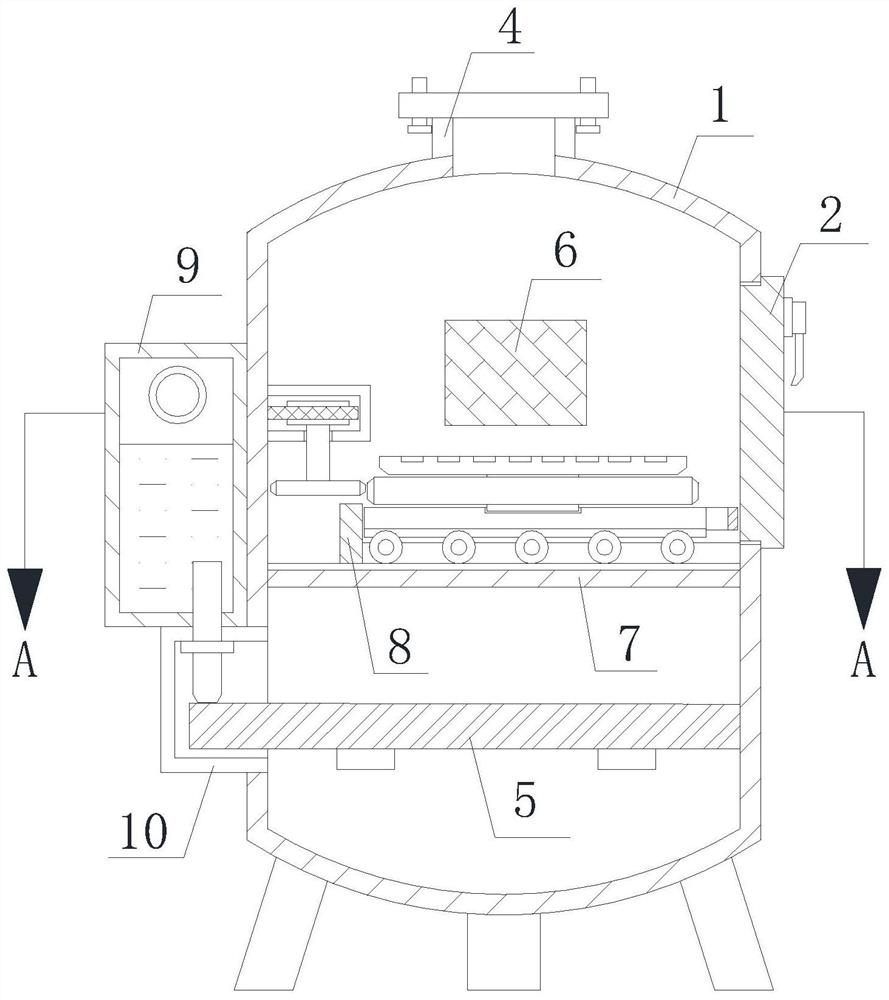

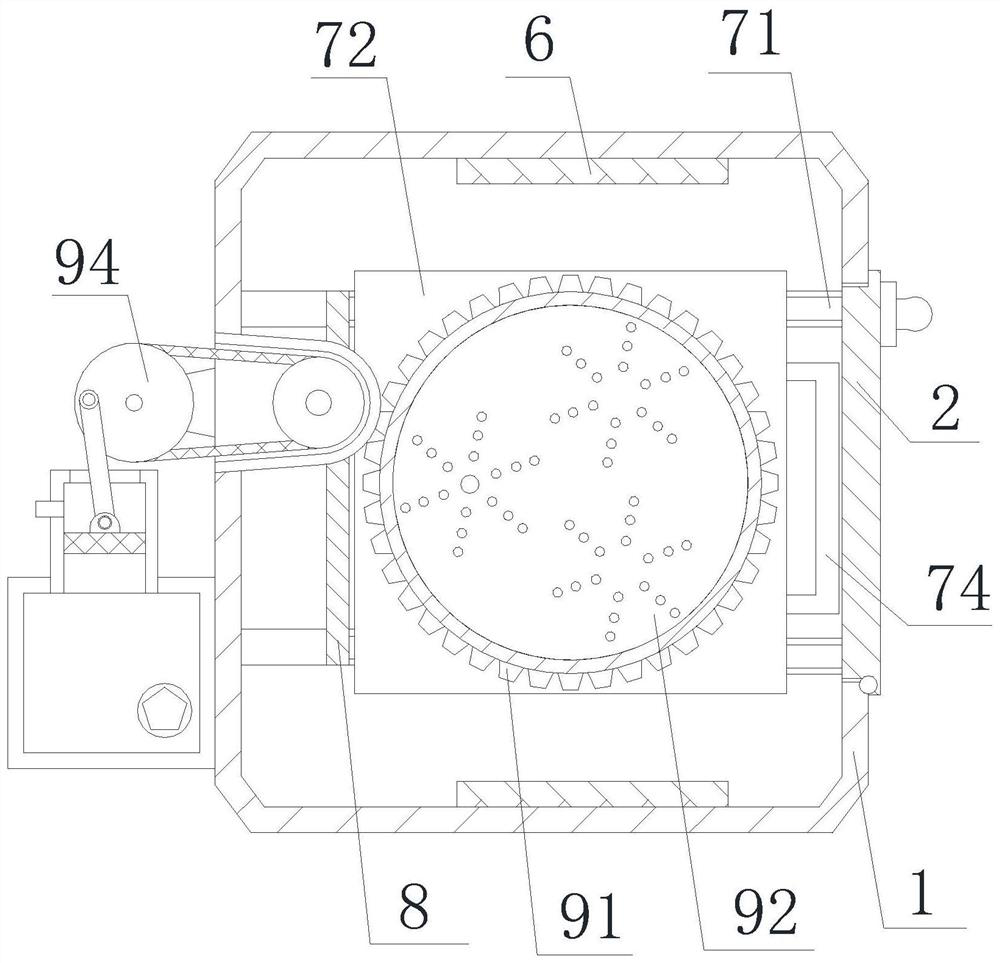

[0027] Attached below Figure 1-5 The present invention is further described with embodiment:

[0028] A heating furnace for heat treatment of wear-resistant parts, comprising a furnace body 1 and a plurality of supporting feet installed at the lower end of the furnace body 1 to ensure the stability of the furnace body 1, the upper end of the furnace body 1 is provided with an air extraction port 4, and the upper end of the air extraction port 4 is A vacuum exhauster can be connected through a flange to ensure that the furnace body 1 will not be oxidized during heat treatment. A furnace door 2 is installed on the side wall of the furnace body 1 to facilitate feeding. The lower part of the inner cavity of the furnace body 1 A lower heating assembly 5 is provided. In this embodiment, the lower heating assembly 5 is a plate-type electric heating wire heater. The plate-type electric heating wire heater should be a technology well known to those skilled in the art, and will not be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com