A kind of multifunctional composite cellulose fiber and its preparation method

A composite cellulose and multi-functional technology, applied in the direction of artificial filaments made of cellulose derivatives, fiber chemical characteristics, rayon manufacturing, etc., can solve the problem of single function and cannot meet the functions of fiber moisture absorption, antibacterial and skin care at the same time To achieve the effects of excellent physical and mechanical properties, simple and reliable production process, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

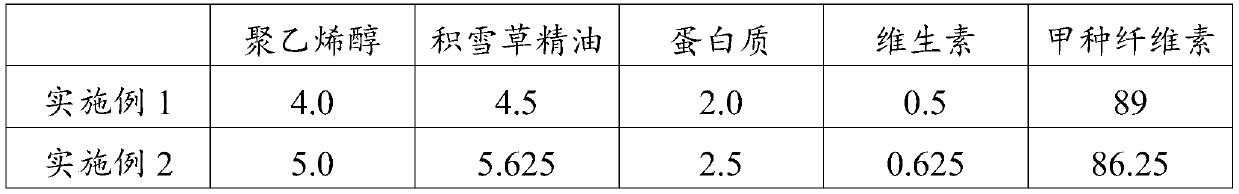

Embodiment 1

[0047] High moisture absorption, antibacterial, skin care multifunctional cellulose fiber with a specification of 1.33dtex×38mm and a preparation method thereof, comprising the following steps:

[0048] (1) Preparation of multifunctional composite additive slurry:

[0049] ① Crush and grind Centella asiatica to obtain powder; weigh Centella asiatica powder and ethanol to meet the mass ratio of 1:10, stir thoroughly, then carry out reflux extraction, and then distill the reflux extraction product processing to obtain Centella asiatica essential oil; the active ingredients in Centella asiatica can be fully extracted by reflux extraction;

[0050] ②Weigh the Centella asiatica essential oil and vitamins respectively to meet the mass ratio of 1:9, and then mix them evenly so that the surface of the vitamins is coated with a layer of Centella asiatica essential oil to prepare oily vitamin mixed slurry: Centella asiatica essential oil in Protect protein and vitamin in water-based sy...

Embodiment 2

[0065] High moisture absorption, antibacterial, skin care multifunctional cellulose fiber with a specification of 1.33dtex×38mm and a preparation method thereof, comprising the following steps:

[0066] (1) Preparation of multifunctional composite additive slurry:

[0067] ① Crush and grind Centella asiatica to obtain powder; weigh Centella asiatica powder and ethanol to meet the mass ratio of 1:10, stir thoroughly, then carry out reflux extraction, and then distill the reflux extraction product , to obtain Centella asiatica essential oil; the active ingredients in Centella asiatica can be fully extracted by reflux extraction;

[0068] ② Weigh Centella Asiatica essential oil and vitamins respectively to meet the mass ratio of 1:9, and then mix them evenly so that the surface of vitamins is coated with Centella Asiatica essential oil to prepare oily vitamin mixed slurry; Centella Asiatica essential oil is mixed with Protect protein and vitamin in water-based system;

[0069] ...

Embodiment 3

[0083] High moisture absorption, antibacterial, skin care multifunctional cellulose fiber with a specification of 1.33dtex×38mm and a preparation method thereof, comprising the following steps:

[0084] (1) Preparation of multifunctional composite additive slurry:

[0085] ① Crush and grind Centella asiatica to obtain powder; weigh Centella asiatica powder and ethanol to meet the mass ratio of 1:10, stir thoroughly, then carry out reflux extraction, and then distill the reflux extraction product , to obtain Centella asiatica essential oil; the active ingredients in Centella asiatica can be fully extracted by reflux extraction;

[0086] ② Weigh Centella Asiatica essential oil and vitamins respectively to meet the mass ratio of 1:9, and then mix them evenly so that the surface of vitamins is coated with Centella Asiatica essential oil to prepare oily vitamin mixed slurry; Centella Asiatica essential oil is mixed with Protect protein and vitamin in water-based system;

[0087] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com