A casting type polyurethane elastomer semi-prepolymer for producing screen printing squeegee

A polyurethane elastomer and screen printing technology, applied in the field of polyurethane elastomer materials, can solve the problems of narrow adjustable range of hardness, difficulty in preparing large-scale structures, large investment in production equipment, etc., to achieve a large adjustable range of hardness and reduce raw material inventory , the effect of long gel time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

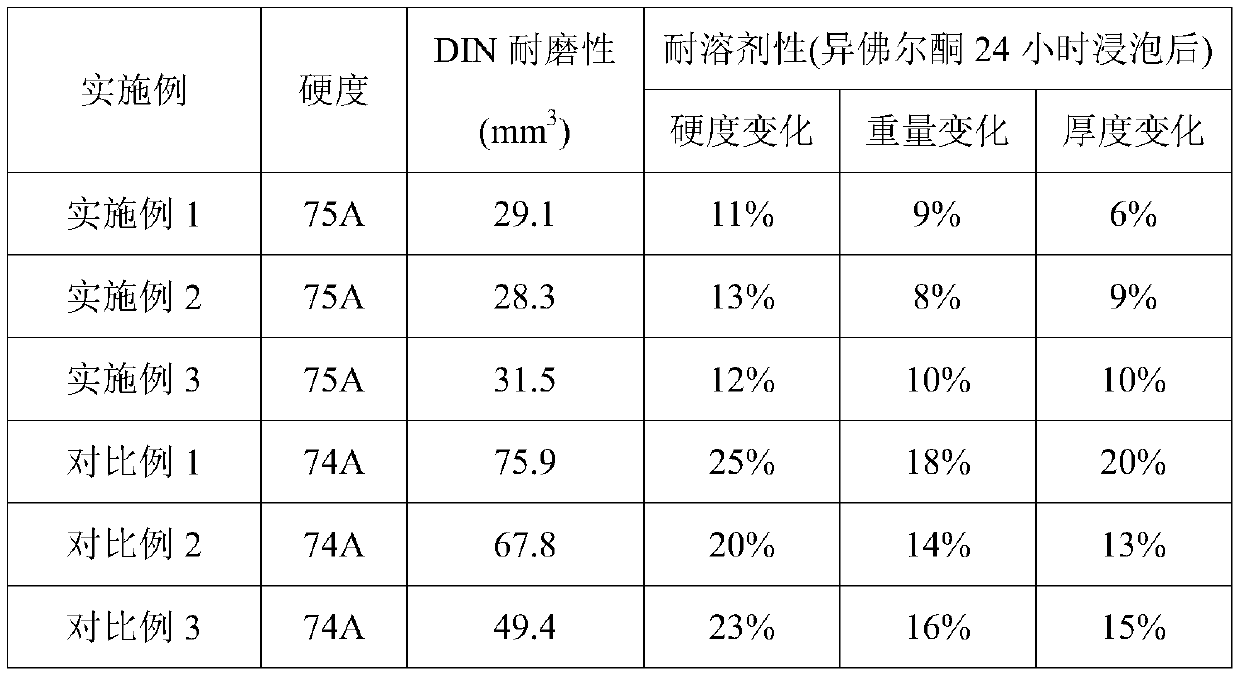

Examples

preparation example Construction

[0062] The preparation method of the polyester polyol with special molecular structure is as follows: Add dibasic acid monomer, small molecular diol and trace catalyst into the reactor, heat up to 140°C to start dehydration, slowly raise the temperature to 220°C, control the fractionation tower The top temperature is less than 103°C. After most of the by-product water is evaporated, the temperature is controlled at 220-230°C for 2 hours, and the acid value is tested by sampling. After the acid value is reduced to less than 30mg KOH / g, turn on the vacuum pump to evacuate , and gradually increase the vacuum degree to remove a small amount of water and excess polyol to reduce the acid value to generate polyester polyol with target molecular weight. When the acid value is 1.5-1.0mg KOH / g, control the temperature at 180-200°C. Add a small amount of epoxy resin E51, continue the reaction, and stop the reaction after the acid value is less than 0.5mg KOH / g.

[0063] The carbodiimide ...

Embodiment approach

[0083] As an embodiment of the present invention, the screen printing squeegee has a density of 1.1 g / cm 3 -1.30g / cm 3 of polyurethane elastomers.

[0084] The fourth aspect of the present invention provides the preparation method of described screen printing squeegee as follows:

[0085] a) Stir the hardener component and the polyol component and mix them evenly;

[0086]b) According to the equivalent ratio of OH / NCO of 0.85-1.0, step a) is mixed with the isocyanate semi-prepolymer component, centrifugally poured, and vulcanized. After vulcanizing in a centrifuge for 1 hour at 100°C, demoulding, then secondary vulcanization at 90-100°C for 8-12 hours, and cutting, the screen printing squeegee can be obtained.

[0087] Mechanism Explanation: This invention adopts a unique preparation process. When using succinic acid to synthesize polyester polyol, it is difficult to reduce the acid value in the later stage. It is difficult to reduce the acid value to below 0.5, or the prod...

Embodiment approach 1

[0088] Embodiment 1: This embodiment provides a castable polyurethane elastomer semi-prepolymer for producing screen printing squeegee, and its preparation raw materials include three parts:

[0089] Isocyanate semi-prepolymer component: an isocyanate semi-prepolymer with an NCO content of 10%-25%, and a viscosity of 1000-5000mPa.s;

[0090] Polyol component: a mixture of polyester polyols added with catalysts, defoamers, colorants, and wear-resistant agents, and the number average molecular weight of the polyester polyols is 1000-4000;

[0091] Hardener component: The hardener component is composed of small molecular polyol or alcohol amine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com