A kind of cyclobenzaprine hydrochloride sublingual spray and preparation method thereof

A technology of cyclobenzaprine hydrochloride and spray, which is applied in the direction of aerosol delivery, anti-inflammatory agent, pharmaceutical formula, etc., to achieve the effect of rapid action, convenient administration and remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

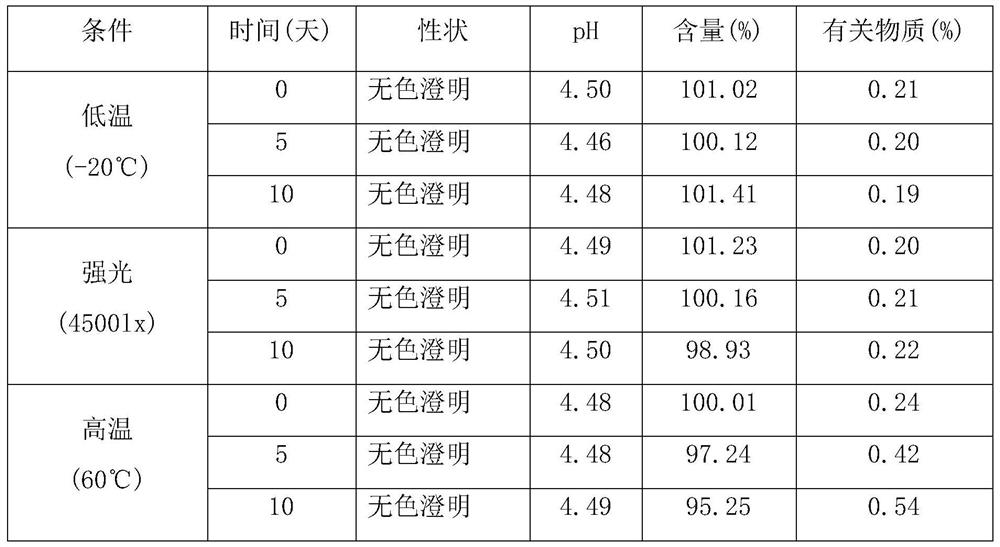

Examples

Embodiment 1

[0022] Example 1 Preparation of cyclobenzaprine hydrochloride-DM-β-cyclodextrin inclusion compound 1

[0023] Weigh an appropriate amount of DM-β-cyclodextrin and add an appropriate amount of distilled water to dissolve it completely, add acetone to dissolve cyclobenzaprine hydrochloride with a mass ratio of 1:2 to DM-β-cyclodextrin under the condition of heating and stirring at 30°C , stirring for an appropriate time until it dissolves completely, the solvent is evaporated to dryness by rotary evaporation, and the obtained solid is vacuum-dried under reduced pressure to obtain that.

Embodiment 2

[0024] Example 2 Preparation of cyclobenzaprine hydrochloride-DM-β-cyclodextrin inclusion compound 2

[0025] Weigh an appropriate amount of DM-β-cyclodextrin and add an appropriate amount of distilled water to dissolve it completely, add acetone-dissolved cyclobenzaprine hydrochloride with a mass ratio of 1:3 to DM-β-cyclodextrin under the condition of heating and stirring at 35°C, Stir for an appropriate time until it dissolves completely, dry the solvent by rotary evaporation, and vacuum-dry the obtained solid under reduced pressure to obtain the obtained product.

Embodiment 3

[0026] Example 3 Preparation of cyclobenzaprine hydrochloride-DM-β-cyclodextrin inclusion compound 3

[0027] Weigh an appropriate amount of DM-β-cyclodextrin and add an appropriate amount of distilled water to dissolve it completely, add acetone-dissolved cyclobenzaprine hydrochloride with a mass ratio of 1:4 to DM-β-cyclodextrin under the condition of heating and stirring at 40°C, Stir for an appropriate time until it dissolves completely, dry the solvent by rotary evaporation, and vacuum-dry the obtained solid under reduced pressure to obtain the obtained product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com