Method for preparing pudding by utilizing poultry egg processing by-products

A technology of by-products and poultry eggs, applied in application, food preservation, food ingredients, etc., can solve the problems of large loss of emulsification and homogenization equipment, difficult filtration to remove insoluble matter, β-cyclodextrin residue, etc., to achieve a wide choice of tastes , The process is simple, the effect of weakening the gel ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

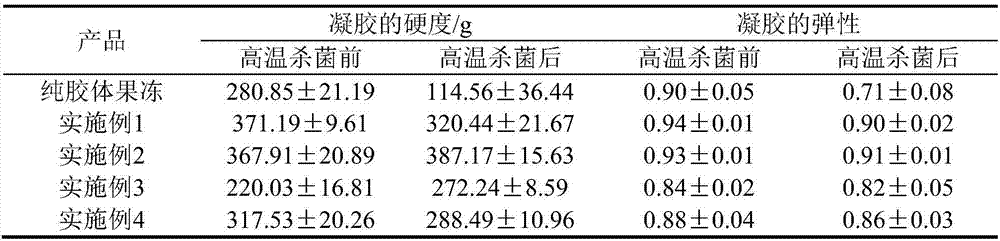

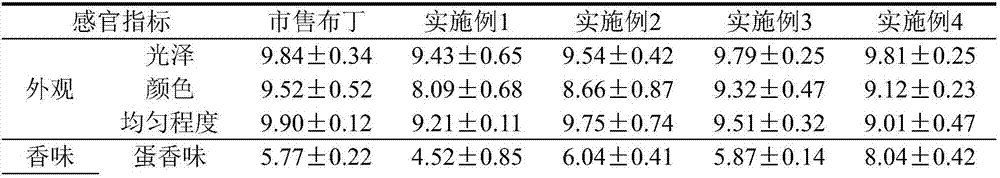

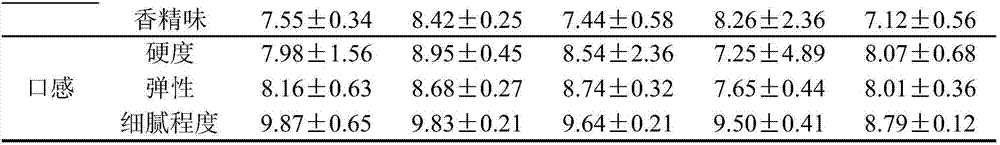

Examples

Embodiment 1

[0030] (1) Take damaged eggs caused by processes such as precooking and peeling during the processing of marinated eggs, and separate egg white gel and egg yolk gel.

[0031] (2) Take 10.00 g of egg white gel and 5.00 g of egg yolk gel and add 76.50 g of water to crush them with a blender, then use a colloid mill to obtain a suspension of broken gel particles, which is degassed. The particle diameter of the broken gel particles after homogenization is ≤20 μm.

[0032](3) Stir the degassed gel broken particle suspension with 7.00g sucrose, 1.08g carrageenan, 0.12g xanthan gum, 0.20g potassium chloride, 0.10g peach essence at 150r / min for 10min, and mix After uniformity, place in an 85°C water bath for hydration for 30 minutes to obtain a colloidal solution.

[0033] (4) Filter the colloidal solution obtained in step (3) to remove insoluble matter and large particles with a particle size greater than 40 mesh, then fill it, and sterilize at 110°C for 25 minutes. After cooling, ...

Embodiment 2

[0036] (1) Take damaged eggs caused by processes such as precooking and peeling during the processing of marinated eggs, and separate egg white gel and egg yolk gel.

[0037] (2) Take 15.52g of egg white gel and 7.19g of egg yolk gel and add 66.05g of water to crush them with a mixer, then use a high-pressure homogenizer to obtain a suspension of the broken gel particles, which is degassed. The particle diameter of the broken gel particles after homogenization is ≤20 μm.

[0038] (3) Stir the degassed gel broken particle suspension and 10.00g sucrose, 0.90g carrageenan, 0.10g xanthan gum, 0.10g potassium chloride, and 0.15g orange essence at 100r / min for 15min, and mix After uniformity, place in an 80°C water bath for hydration for 20 minutes to obtain a colloidal solution.

[0039] (4) Filter the colloidal solution obtained in step (3) to remove insoluble matter and large particles with a particle size greater than 40 mesh, then fill it, and sterilize at 115°C for 20 minutes...

Embodiment 3

[0042] (1) The salted egg white is heat-treated at 80-100°C for 20-40 minutes to form a gel, the gel is broken into granules, and the desalted salted egg white gel is obtained by washing and immersing the desalting method;

[0043] (2) Take 35.00 g of desalted salted egg white gel and add 52.35 g of water to crush it with a mixer, then use a high-pressure homogenizer to obtain a suspension of broken gel particles, which is degassed. The particle diameter of the broken gel particles after homogenization is ≤20 μm.

[0044] (3) Stir the degassed gel broken particle suspension with 12.00g sucrose, 0.36g carrageenan, 0.04g xanthan gum, 0.05g potassium chloride, and 0.20g milk essence at 200r / min for 10min, and mix well Then put it in a water bath at 75°C for hydration for 20 minutes to obtain a colloidal solution.

[0045] (4) Filter the colloidal solution obtained in step (3) to remove insoluble matter and large particles with a particle size greater than 40 mesh, then fill it, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com