Construction method for rock riverbed bearing platform in water

A technology of underwater bearing platform and construction method, which is applied in basic structure engineering, erecting/assembling bridges, bridges, etc., can solve the problems of difficult construction of underwater bearing platform and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

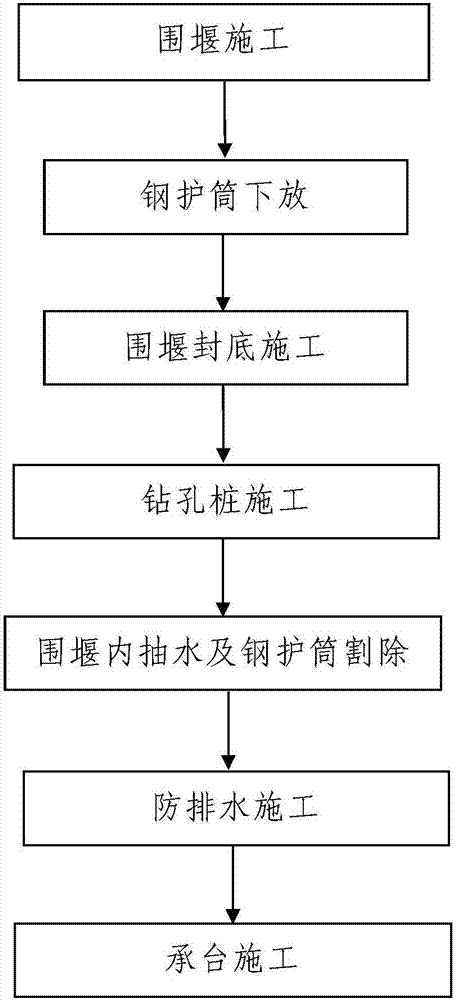

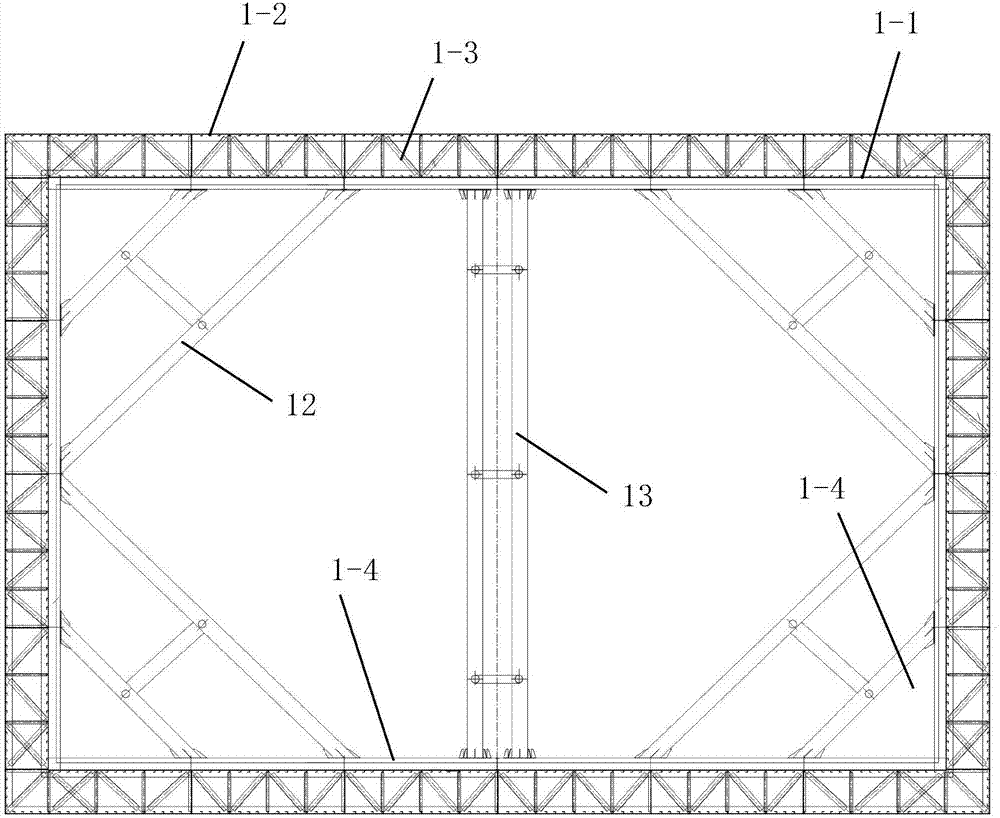

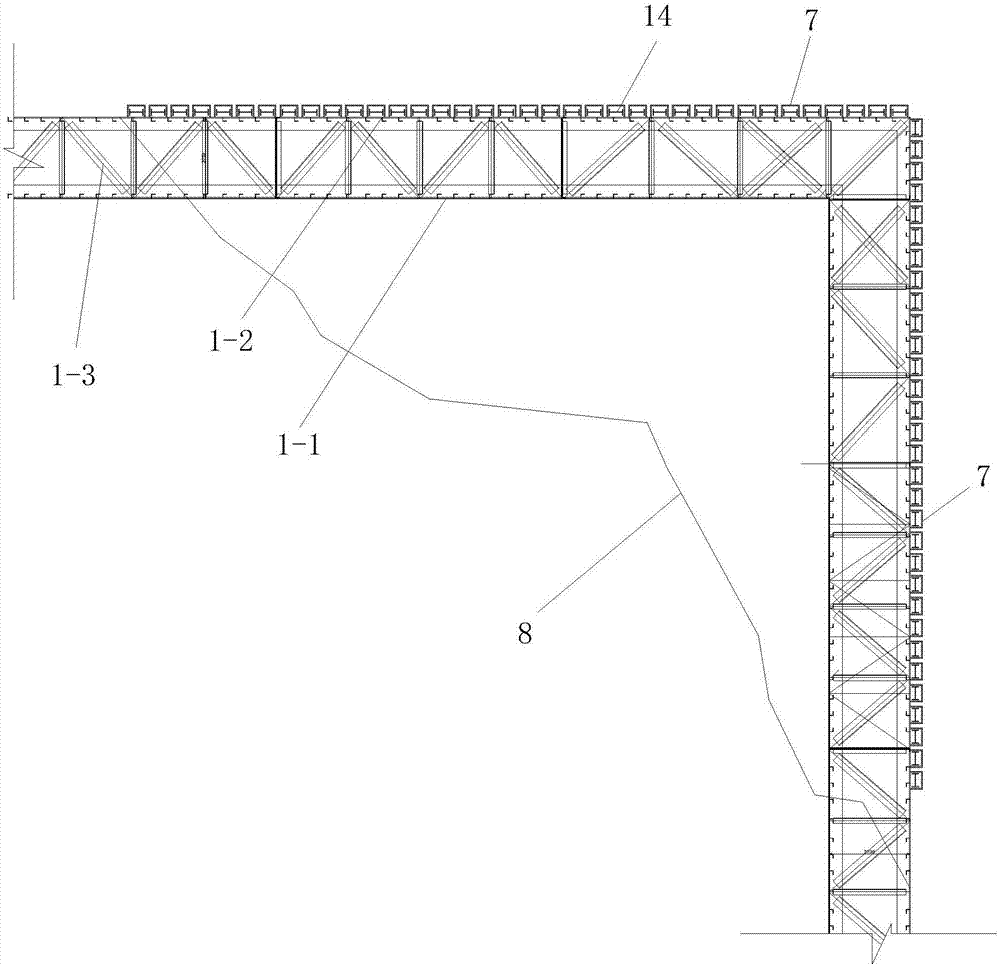

[0116] Such as figure 1 Shown is a kind of rock river bed water bearing platform construction method, combines figure 1 , Figure 8 and Figure 9 , the constructed water cap 33 is a reinforced concrete cap formed by steel cofferdam 1-4 construction, and the water cap 33 is supported by a plurality of vertically arranged bored piles 17; the steel cofferdam 1-4 is supported on the rocky riverbed 5, the bored pile 17 is a reinforced concrete pile and it is on the hard rock 18 in the rocky riverbed 5;

[0117] When carrying out construction to the bearing platform 33 in the water, the process is as follows:

[0118] Step 1, cofferdam construction: according to the conventional cofferdam sinking construction method, the steel cofferdam 1-4 is sunk from top to bottom to the construction position of the cap in the water, and the steel cofferdam 1-4 is supported on On the rocky river bed 5;

[0119] Step 2, lowering the steel casing: according to the conventional steel casing low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com