Extraction and purification process of anticoagulant peptide in centipedes

An anticoagulant peptide and centipede technology, which is applied in the field of deep processing of pharmaceutical raw materials, can solve the problems of low activity, reduced hemolytic activity, and low efficiency of active ingredients, and achieves the effects of long coagulation time and strong anticoagulation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

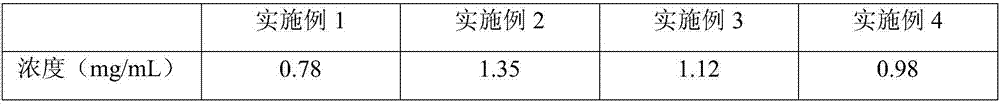

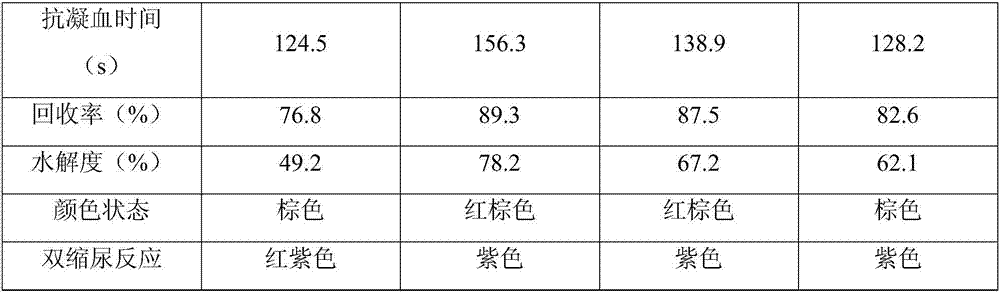

[0023] Example 1: A kind of extraction and purification process of centipede anticoagulant peptide

[0024] A process for extracting and purifying centipede anticoagulant peptide, said process comprising the following steps:

[0025] (1) Take the fresh and alive adults of centipede, put them in a liquid nitrogen tank quickly, take them out after freezing for 10 minutes and grind them into powder, and pour the powder into a centrifuge tube, add a 12% ammonium sulfate aqueous solution with a mass fraction of 0.01 times the volume Proteinase K aqueous solution, treated at 55°C for 5 minutes; the amount of ammonium sulfate aqueous solution added is two-thirds of the length of the centrifuge tube. The concentration of the proteinase K aqueous solution is 50-100 micrograms / ml, in this embodiment it is 50 micrograms / ml.

[0026] (2) Take the product processed in step (1), put the centrifuge tube in boiling water and boil for 2 minutes, then place it on ice to cool, shake it up and d...

Embodiment 2

[0030] Example 2: A kind of extraction and purification process of centipede anticoagulant peptide

[0031] A process for extracting and purifying centipede anticoagulant peptide, said process comprising the following steps:

[0032] (1) Take the fresh and alive adults of the centipede, put them in a liquid nitrogen tank quickly, take them out after freezing for 20 minutes and grind them into powder, and pour the powder into a centrifuge tube, add a 25% ammonium sulfate aqueous solution with a mass fraction of 0.03 times the volume Proteinase K aqueous solution, treated at 56°C for 12 minutes; the amount of ammonium sulfate aqueous solution added is two-thirds of the length of the centrifuge tube. The concentration of the proteinase K aqueous solution is 50-100 micrograms / ml, in this embodiment it is 60 micrograms / ml.

[0033] (2) Take the processed product of step (1), put the centrifuge tube in boiling water and boil for 6 minutes quickly, then place it on ice to cool, shak...

Embodiment 3

[0037] Example 3: A kind of extraction and purification process of centipede anticoagulant peptide

[0038] A process for extracting and purifying centipede anticoagulant peptide, said process comprising the following steps:

[0039] (1) Take the fresh and alive adults of the centipede, place them quickly in a liquid nitrogen tank, take out and grind them into powder after freezing for 25 minutes, and pour the powder into a centrifuge tube, add a 22% ammonium sulfate aqueous solution with a mass fraction of 0.03 times the volume Proteinase K aqueous solution, treated at 57°C for 12 minutes; the amount of ammonium sulfate aqueous solution added is two-thirds of the length of the centrifuge tube. The concentration of the proteinase K aqueous solution is 50-100 micrograms / ml, in this embodiment it is 100 micrograms / ml.

[0040] (2) Take the processed product of step (1), put the centrifuge tube in boiling water and boil for 6 minutes quickly, then place it on ice to cool, shake ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com