Chiral poly alkyne nano-fiber preparation method

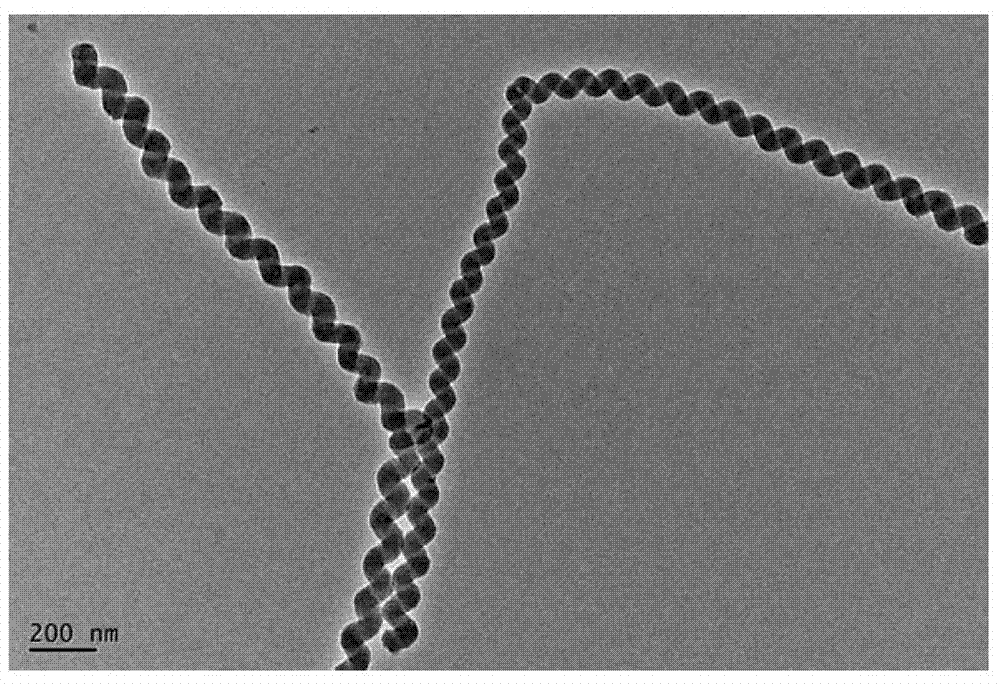

A nanofiber and chiral technology, which is applied in the field of chiral polyyne nanofiber and its homogeneous preparation, can solve the problems of high reaction temperature, high preparation cost, and complicated equipment, and achieve cheap and easy-to-obtain raw materials, uniform diameter, and pitch uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] Preparation of Alkyne Monomer Solutions. Dissolve the alkyne monomer in the solvent to a certain concentration at room temperature, and stir well to form a homogeneous alkyne monomer solution. Wherein the alkyne monomer can be at least one of acetylene, diacetylene and phenylacetylene. The solvent of the alkyne monomer solution can be ethanol or acetone. The concentration of the alkyne monomer solution can be 0.2 to 20 wt%, preferably 3 to 10 wt%. If the concentration is too high, the fiber will grow too fast and cause size inhomogeneity. If the concentration is too low, the growth will be too slow and the anisotropy of growth will not be obvious. , it is difficult to obtain a chiral structure, and an appropriate concentration is conducive to the preparation of chiral polyyne nanofibers with uniform size.

[0031] Drop the alkyne monomer solution into the lining of the hydrothermal kettle with the catalyst at a rate of 2-5ml / min until the alkyne monomer solution is co...

Embodiment 1

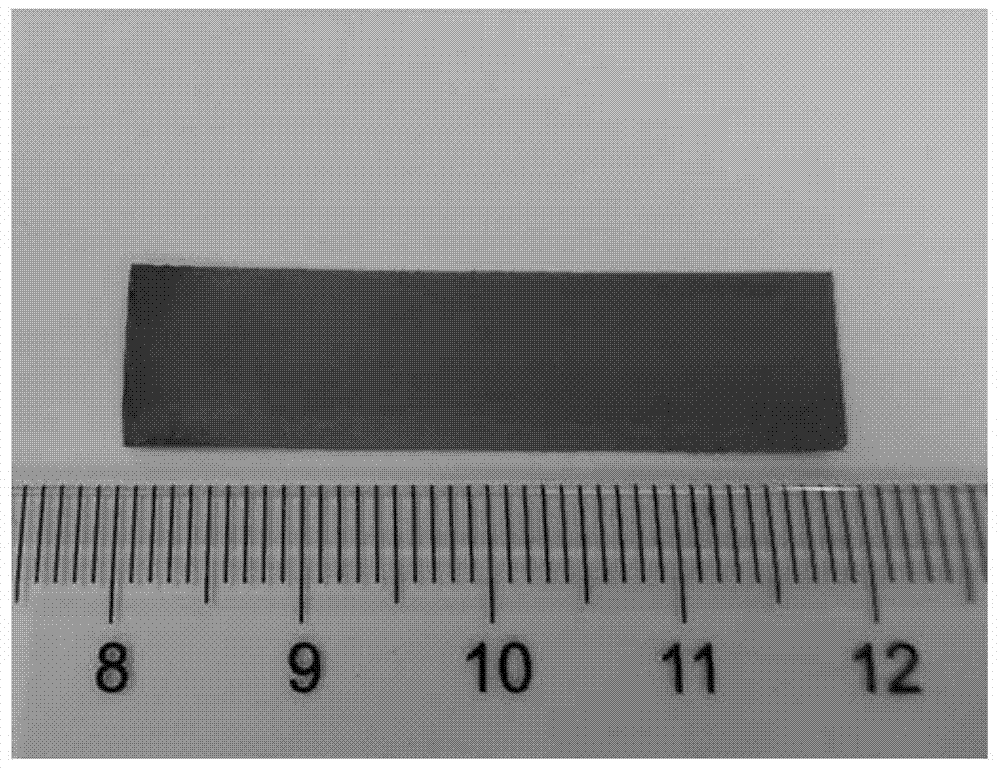

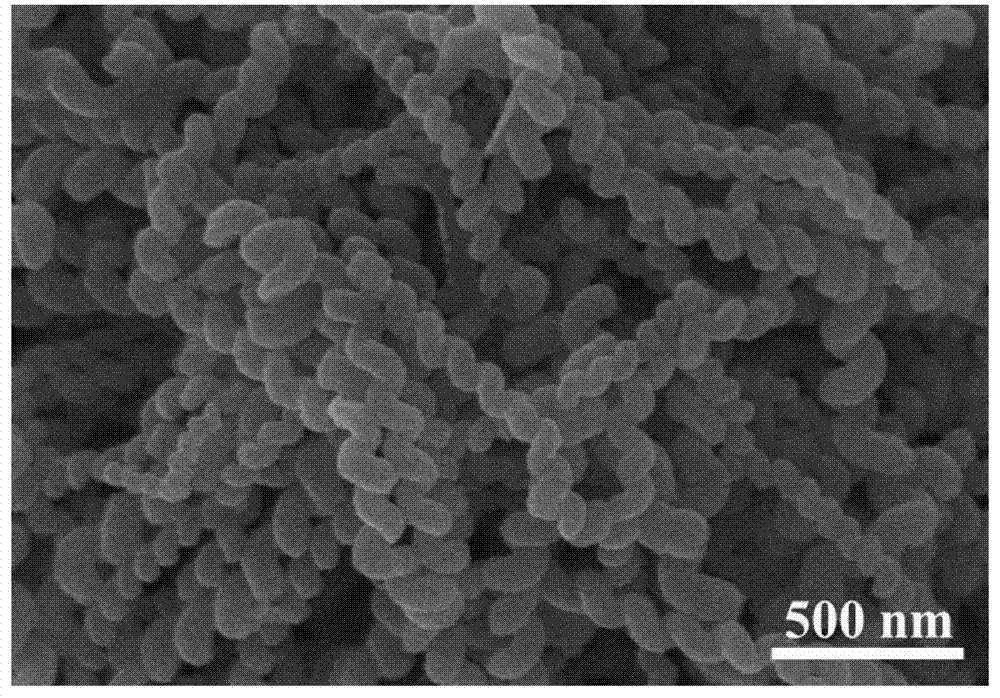

[0036] Dissolve acetylene in 30ml ethanol to 3wt% at room temperature, and stir well to form a homogeneous acetylene monomer solution. Place 0.022g of acetone-cleaned copper sheet (the molar ratio of acetylene in the dropped acetylene monomer solution is 1:80) in the lining of a 40ml hydrothermal kettle, and slowly drop in 30ml of it at a speed of 2ml / min. Acetylene monomer solution until the catalyst is completely submerged. Ammonia water (volume 100μl, molar concentration 0.35mol / L) was added dropwise to the above system to 2*10 -3 wt% (the molar ratio of ammonia gas in ammonia water to the acetylene in the dripped acetylene monomer solution is 1:800), let it stand at room temperature for 3 hours, and then place it in a muffle furnace at 150°C for 36 hours. After the reaction is finished and the temperature is naturally lowered to room temperature, the product is washed with ethanol, and the obtained chiral polyyne nanofiber film is sealed and stored in an ethanol solution....

Embodiment 2

[0043] Dissolve phenylacetylene in 30ml of ethanol to 10wt% at room temperature, and fully stir to form a uniform phenylacetylene monomer solution. 0.034g of acetone-cleaned nickel sheet (the molar ratio of phenylacetylene in the dropped phenylacetylene monomer solution is 1:50) is placed in a 40ml hydrothermal kettle liner, and slowly dripped at a rate of 2ml / min. 30ml of the above solution to completely submerge the catalyst. Add dropwise hydrazine hydrate to the system to 2*10 -3 wt% (to the phenylacetylene molar ratio in the dropped phenylacetylene monomer solution is 1:1500), let it stand at room temperature for 2 hours, and place it in a muffle furnace at 180°C for 45 hours. After the reaction is finished and the temperature is naturally lowered to room temperature, the product is washed with ethanol, and the obtained chiral polyyne nanofiber film is sealed and stored in an ethanol solution.

[0044] Figure 7 It is a digital photo of the chiral polyphenylene vinylene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com