Method for preparing polynary nano-cage composite material

A technology of composite materials and nanocages, which is applied in the field of preparing ternary non-spherical composite materials, can solve the problems of lack of morphological diversity, limited morphologies, hindering the use of MOF and its derivatives, and achieve easy control of operating conditions and separation and agglomeration The effect of small degree and good particle size dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Weigh 0.2910g (1.0mmol) of cobalt nitrate and 0.3284g (4.0mmol) of 2-methylimidazole and dissolve them in 25mL of methanol to form two solutions. Then, the 2-methylimidazole solution was quickly poured into the cobalt nitrate solution under stirring, and after stirring for 5 minutes, the resulting mixed solution was aged at room temperature for 24 hours. The purple precipitate was collected by centrifugation and dried at 60°C for 12 hours to obtain the product ZIF-67 nanocrystals.

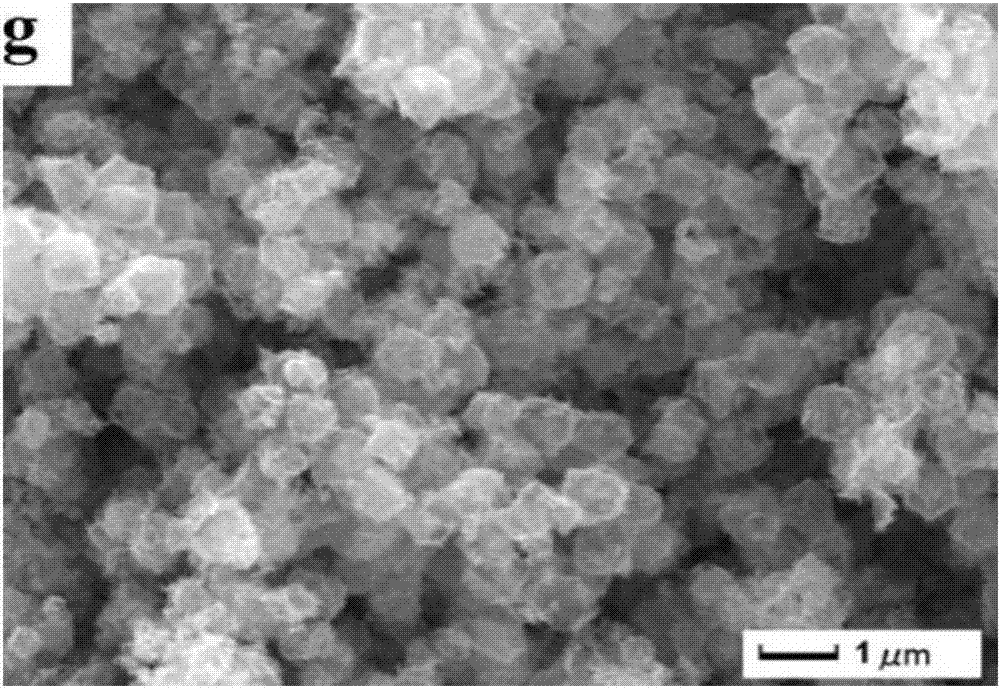

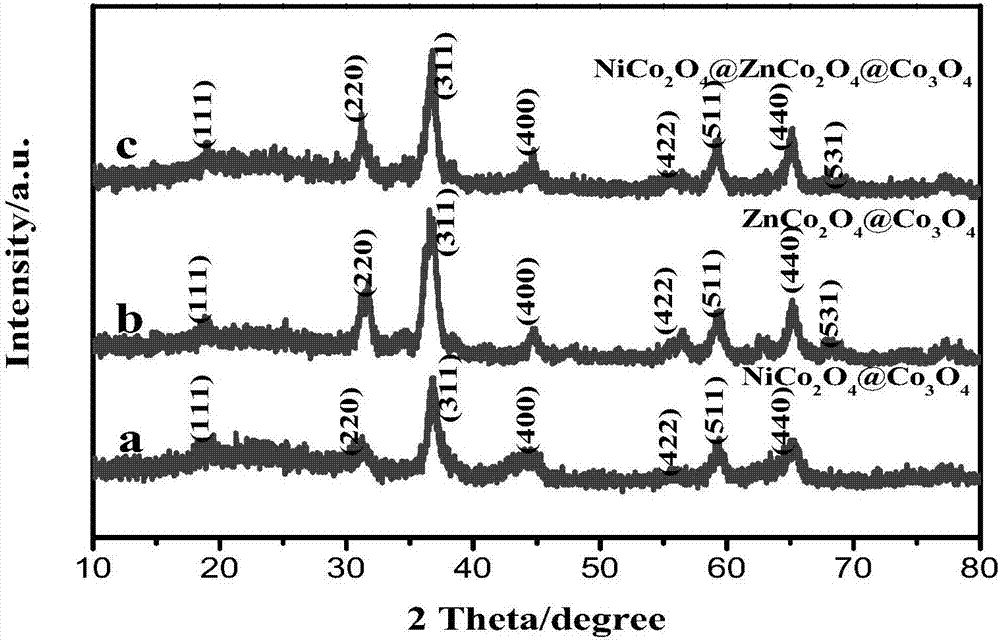

[0032] 40 mg of ZIF-67 was dispersed in 25 mL of ethanol containing 80 mg of zinc nitrate. After stirring for 1 h, ZIF-67 / Zn-Co hydroxide nanocage particles were formed, centrifuged and collected, and finally dried at 60 °C for 12 h. Then, in air at 350°C at 2°C min -1 The ZIF-67 / Zn-Co hydroxide nanocage particles were annealed at a rate of 2 hours to obtain ZnCo 2 o 4 @Co 3 o 4 Hollow nanocages.

[0033] 40 mg of ZIF-67 was dispersed in 25 mL of ethanol containing 80 mg of nickel nit...

Embodiment 2

[0036]Weigh 0.2910g (1.0mmol) of cobalt nitrate and 0.3284g (4.0mmol) of 2-methylimidazole and dissolve them in 25mL of methanol to form two solutions. Then, the 2-methylimidazole solution was quickly poured into the cobalt nitrate solution under stirring, and after stirring for 5 minutes, the resulting mixed solution was aged at room temperature for 24 hours. The purple precipitate was collected by centrifugation and dried at 60°C for 12 hours to obtain the product ZIF-67 nanocrystals.

[0037] 40 mg of ZIF-67 was dispersed in 25 mL of ethanol containing 80 mg of zinc nitrate. After stirring for 1 h, ZIF-67 / Zn-Co hydroxide nanocage particles were formed, centrifuged and collected, and finally dried at 60 °C for 12 h. Then, in air at 300°C at 2°C min -1 The ZIF-67 / Zn-Co hydroxide nanocage particles were annealed at a rate of 2 hours to obtain ZnCo 2 o 4 @Co 3 o 4 Hollow nanocages. 40 mg of ZIF-67 was dispersed in 25 mL of ethanol containing 80 mg of nickel nitrate. Aft...

Embodiment 3

[0040] Weigh 0.2910g (1.0mmol) of cobalt nitrate and 0.3284g (4.0mmol) of 2-methylimidazole and dissolve them in 25mL of methanol to form two solutions. Then, the 2-methylimidazole solution was quickly poured into the cobalt nitrate solution under stirring, and after stirring for 5 minutes, the resulting mixed solution was aged at room temperature for 24 hours. The purple precipitate was collected by centrifugation and dried at 60°C for 12 hours to obtain the product ZIF-67 nanocrystals.

[0041] 40 mg of ZIF-67 was dispersed in 25 mL of ethanol containing 80 mg of zinc nitrate. After stirring for 1 h, ZIF-67 / Zn-Co hydroxide nanocage particles were formed, centrifuged and collected, and finally dried at 60 °C for 12 h. Then, in air at 350°C at 2°C min -1 The ZIF-67 / Zn-Co hydroxide nanocage particles were annealed at a rate of 3 hours to obtain ZnCo 2 o 4 @Co 3 o 4 Hollow nanocages.

[0042] 40 mg of ZIF-67 was dispersed in 25 mL of ethanol containing 80 mg of nickel nit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com