Intelligent ground lead loading platform

A grounding wire and platform technology, applied in the field of intelligent grounding wire loading platform, can solve the problems of a small number of grounding wires, threatening the life safety of operators, grounding accidents, etc., and achieve the effect of sufficient friction, large contact area and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

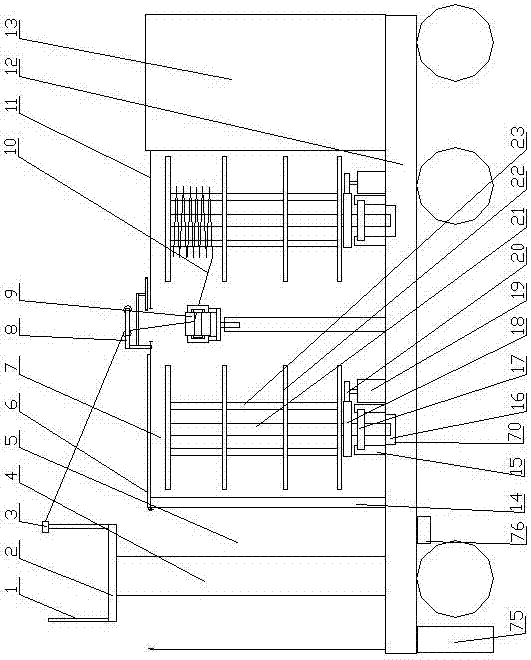

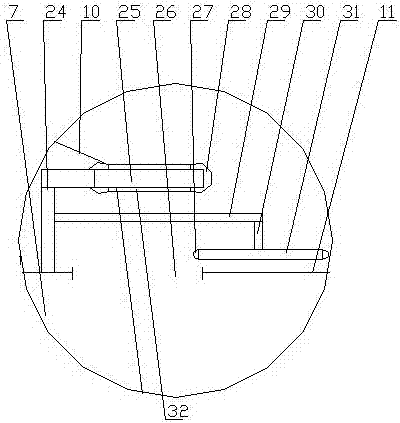

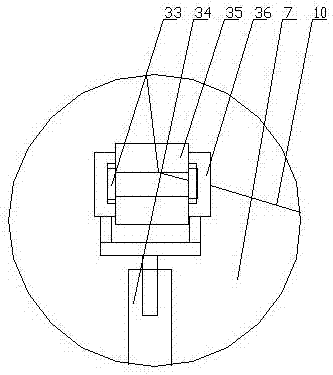

[0054] Embodiment one, such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 8 As shown, the present invention provides an intelligent grounding wire loading platform, including a car body 12, the front end of the car body 12 is connected to the front end 13, and the car body 12 is provided with a compartment 11, and the compartment 11 is passed through a compartment The plate 14 is provided with a collection box 7 and an operation box 5. Four ground wire collection mechanisms are arranged on the vehicle body 12 in the collection box 7, and a first ground wire collection mechanism is arranged on the vehicle body 12 among the four ground wire collection mechanisms. Guide mechanism 9, an opening 26 is set on the top of the compartment 11, a second guide mechanism 8 is set on the opening 26, a first lifting mechanism 4 is set on the car body 12 in the operation box 5, and the first lifting mechanism 4. A workbench is set on the top, and a ground wire clamping mechan...

Embodiment 2

[0069] Embodiment two, such as Figure 5 Shown, its difference with embodiment one is:

[0070] The self-generating module includes a mounting frame 40 hingedly arranged on the upper part of the outer side wall of the compartment 11, a solar panel 44 is arranged on the mounting frame 40, and a telescopic rotating mechanism is arranged on the lower part of the side wall outside the compartment 11, and the telescopic rotating mechanism The end of the mechanism is rotatably connected with the lower end of the mounting frame 40 .

[0071] A heat insulation board 43 bonded to the solar cell panel 44 is arranged in the installation frame 40, and several heat conduction blocks 42 are arranged on the heat insulation board 43, and the upper surface of the heat conduction block 42 is in contact with the solar cell. The lower surface of the plate 44 corresponds, and the lower surface of the heat conduction block 42 is provided with a thermoelectric power generation sheet 41 . The teles...

Embodiment 3

[0075] Embodiment three, such as Figure 6 and Figure 7 Shown, its difference with embodiment one is:

[0076] A temperature and humidity monitoring module is installed in the collection compartment 7 . The temperature and humidity monitoring module includes a temperature and humidity monitoring mechanism 50, a control mechanism 51, a ventilating mechanism and a temperature control mechanism 49 arranged in the collection compartment 7, the temperature and humidity monitoring mechanism 50 includes a temperature and humidity sensor, and the control mechanism 51 includes a single-chip microcomputer. The temperature and humidity monitoring module is installed in the collection compartment. Most of the grounding wires are copper wires wrapped with an insulating layer. When the storage temperature and humidity are not suitable, the aging of the insulating layer will be accelerated and the copper wire will be corroded, thereby reducing the safety of the grounding wire. Therefore,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com