Cage structure lithium battery positive pole

A cage-shaped structure, lithium battery technology, applied in battery electrodes, secondary batteries, structural parts, etc., can solve the problems of poor heat resistance of ternary lithium batteries, affecting the normal operation of batteries, and increasing battery temperature, so as to improve the monomer Energy density, the effect of improving the energy density of the monomer, and improving the cut-off voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

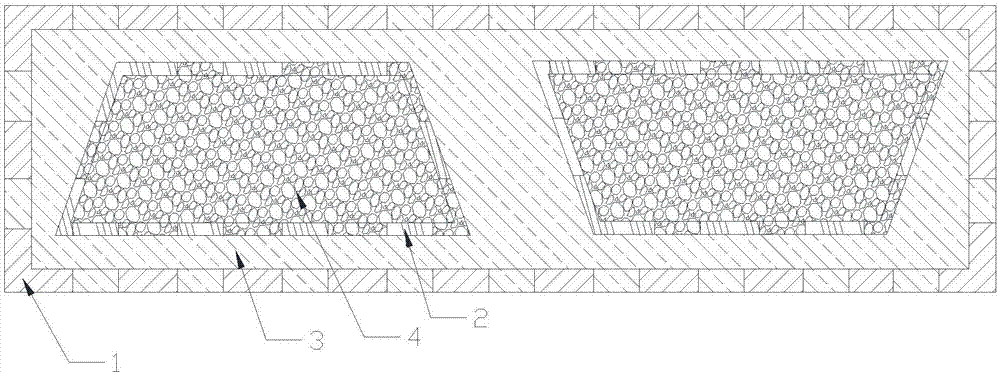

[0024] Such as figure 1 As shown, in this embodiment, the positive electrode of the cage-shaped lithium battery of the present invention includes a first cage-shaped structure 1 and a second cage-shaped structure 2, and the second cage-shaped structure 2 is arranged on the first cage-shaped structure 1 Inside, the cavity between the first cage structure 1 and the second cage structure 2 is provided with a first doped filler 3, and the cavity inside the second cage structure 2 is provided with a first Two-doped filler 4 . Wherein, the first cage structure 1 is a rectangular parallelepiped columnar structure uniformly provided with through holes on the side walls, the first doped filler 3 is arranged in the through holes, and the second cage structure 2 It is a columnar structure with a trapezoidal axial cross-section uniformly provided with via holes on the side walls, and the first doped filling body 3 is arranged in the via holes. Moreover, in this embodiment, two second ca...

Embodiment 2

[0028] In this embodiment, the structure of the positive electrode of the cage-shaped lithium battery of the present invention is the same as that of the positive electrode of the cage-shaped lithium battery in Example 1, the difference lies in: the first cage structure 1 and the second The specific composition of the cage structure 2, the first doped filling body 3 and the second doped filling body 4 is the same as that of the first cage structure 1 and the second cage structure 2 in Example 1. , The specific compositions of the first doped filling body 3 and the second doped filling body 4 are different.

[0029] Wherein, the first cage structure 1 is made of the following raw materials: 15wt% lithium cobaltate, 15wt% lithium manganate and 70wt% lithium nickelate; the second cage structure 2 is made of the following raw materials: 25wt% % lithium cobaltate, 5wt% lithium manganate and 70wt% lithium nickelate; the first doped filling body 3 is composed of the following compone...

Embodiment 3

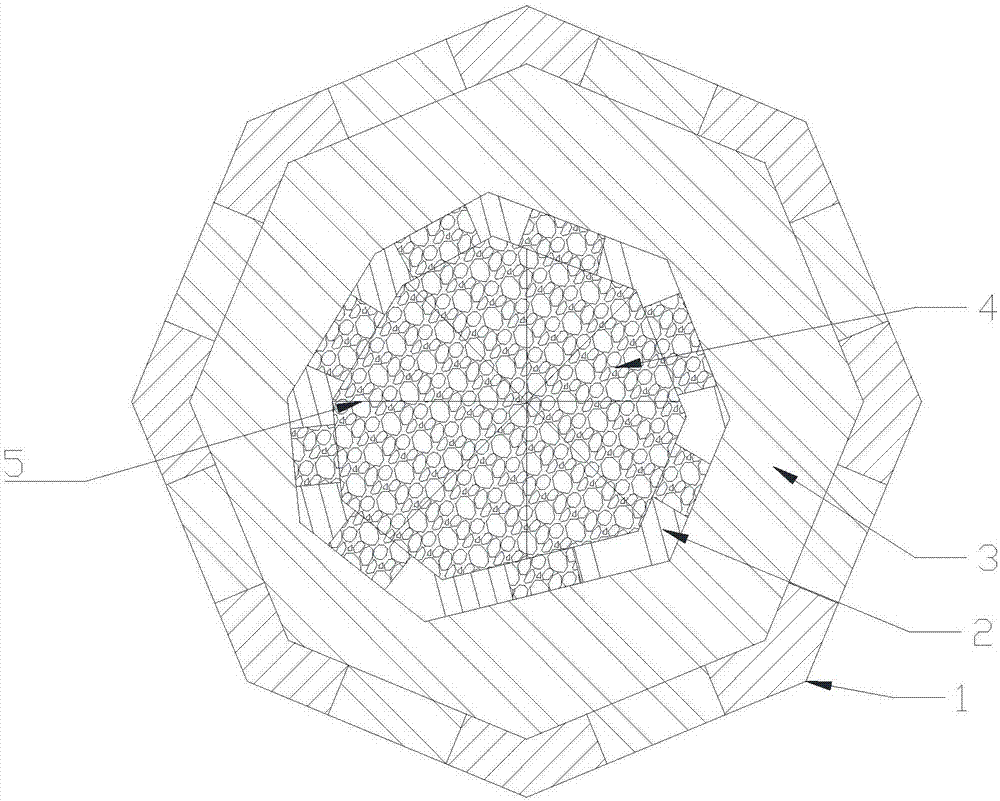

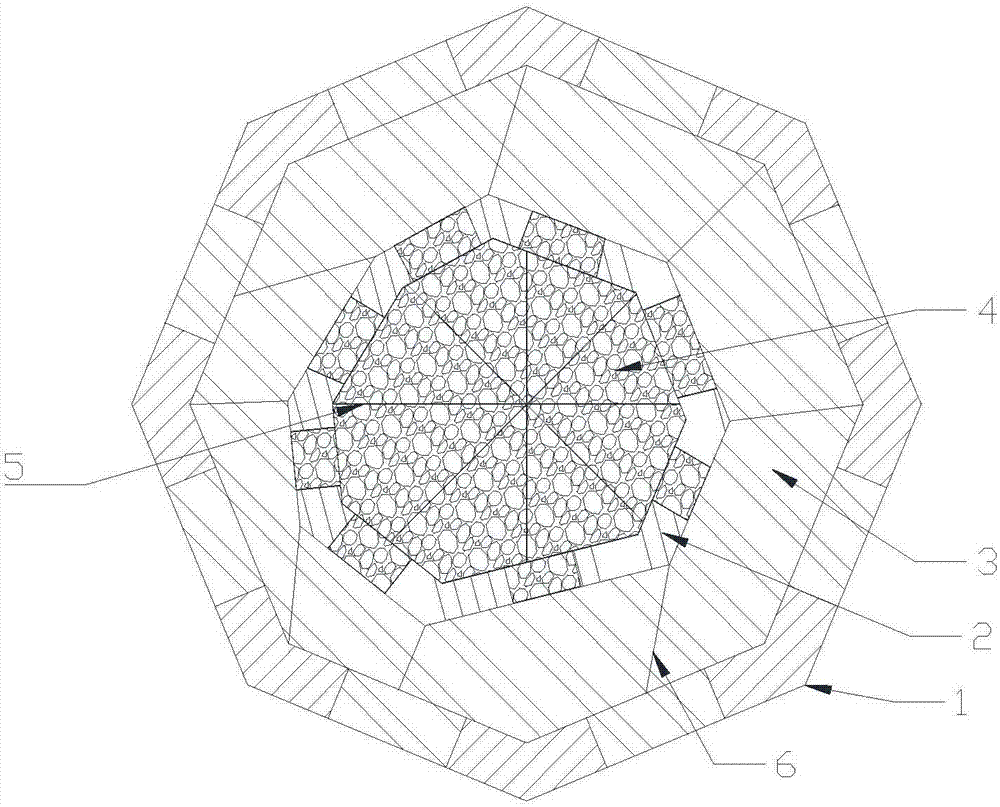

[0032] Such as figure 2 As shown, the positive electrode of the cage structure lithium battery of the present invention includes a first cage structure 1 and a second cage structure 2, the second cage structure 2 is arranged in the first cage structure 1, and the second cage structure A first doped filler 3 is arranged in the cavity between the cage structure 1 and the second cage structure 2, and a second doped filler is arranged in the inner cavity of the second cage structure 2 4. Wherein, the first cage structure 1 is an octagonal prism structure with a regular octagonal axial cross-section with through holes evenly provided on the side walls, and the first doped filling body 3 is arranged in the through holes, and the The second cage structure 2 is a columnar structure with an irregular octagonal axial cross-section uniformly provided with conduction holes on the sidewalls, and the first doped filler 3 is disposed in the conduction holes. Moreover, in this embodiment, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com