Controllable energy store and method for operating controllable energy store

An energy storage, electric energy storage technology, applied in vehicle energy storage, parallel operation of DC power supply, irreversible DC power input conversion to AC power output and other directions, can solve the problem of battery current flow, energy storage failure, total voltage Advanced problems, to achieve the effect of reducing the number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

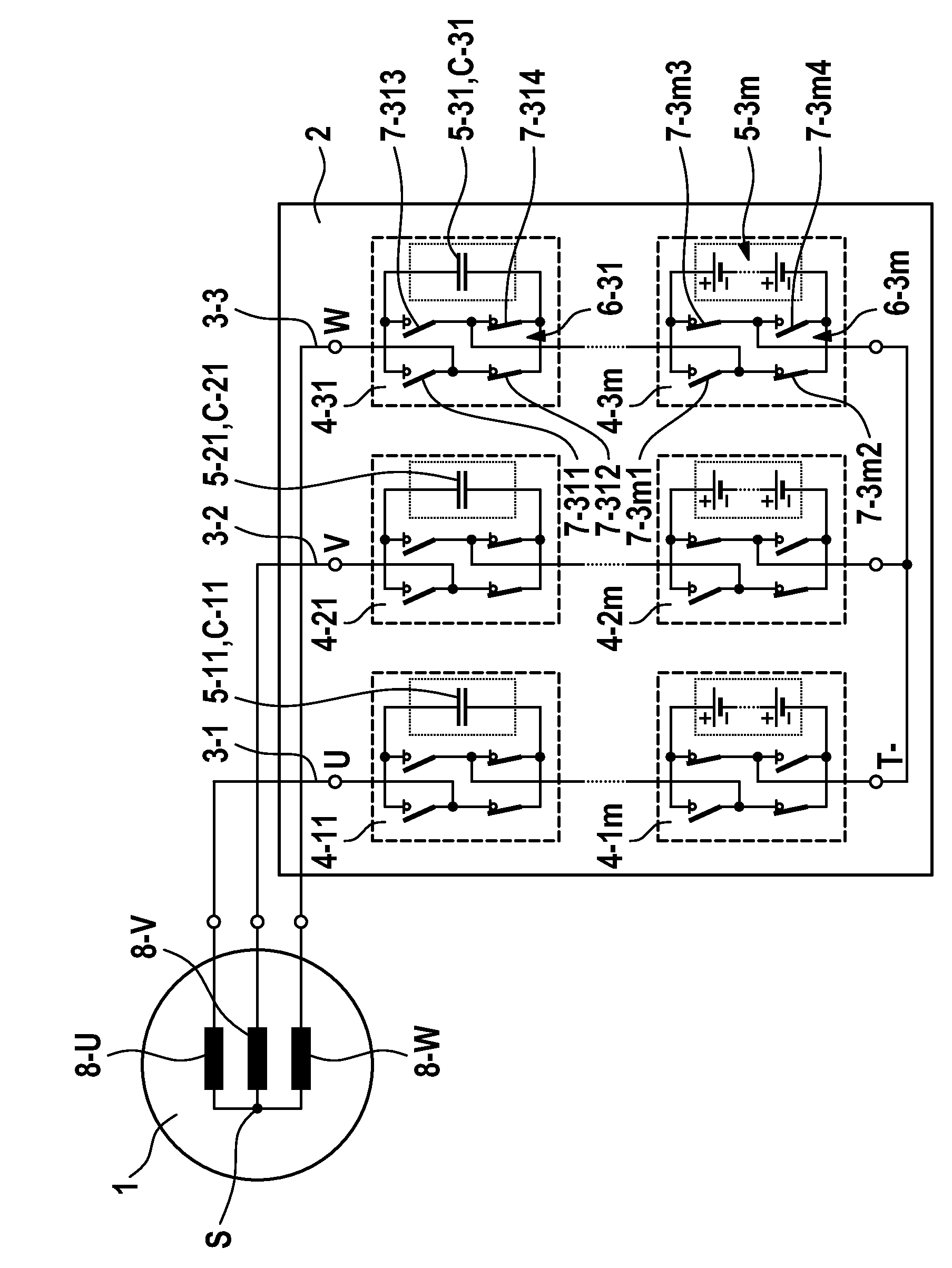

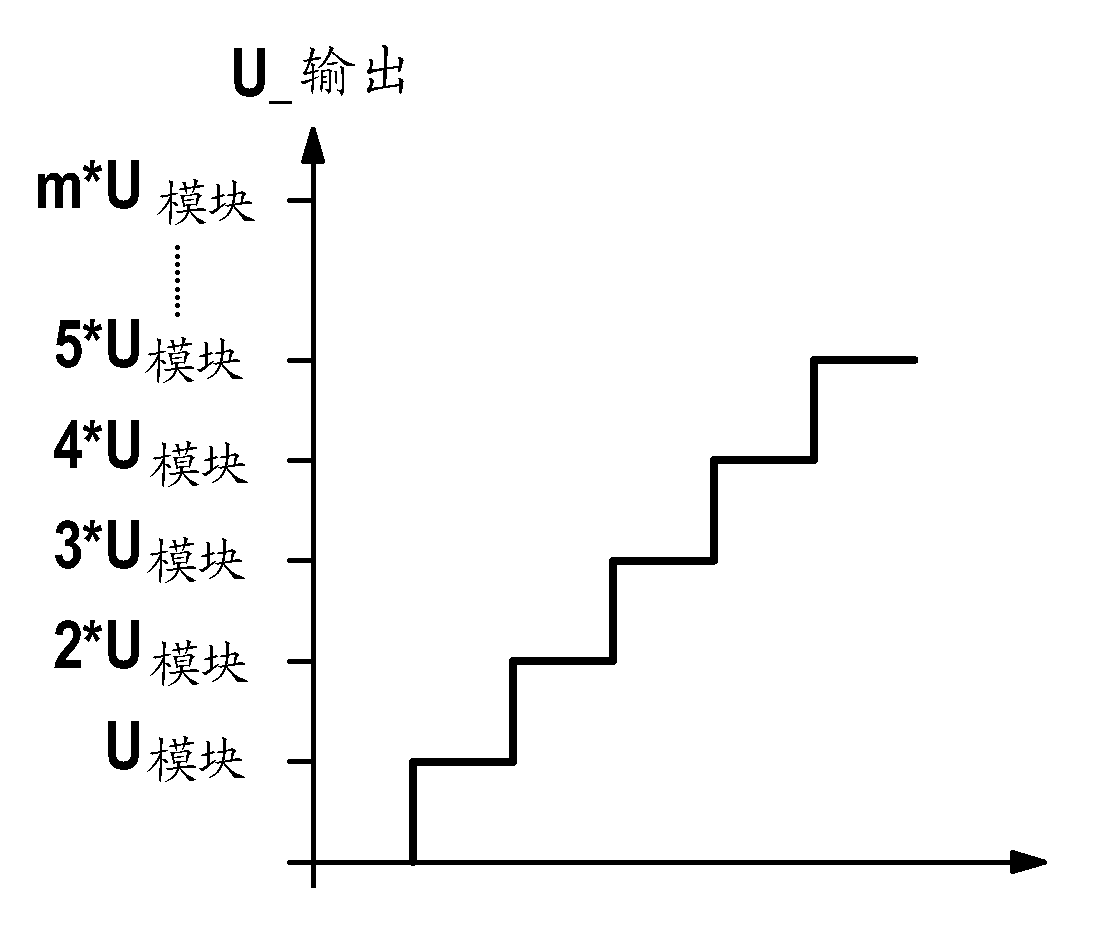

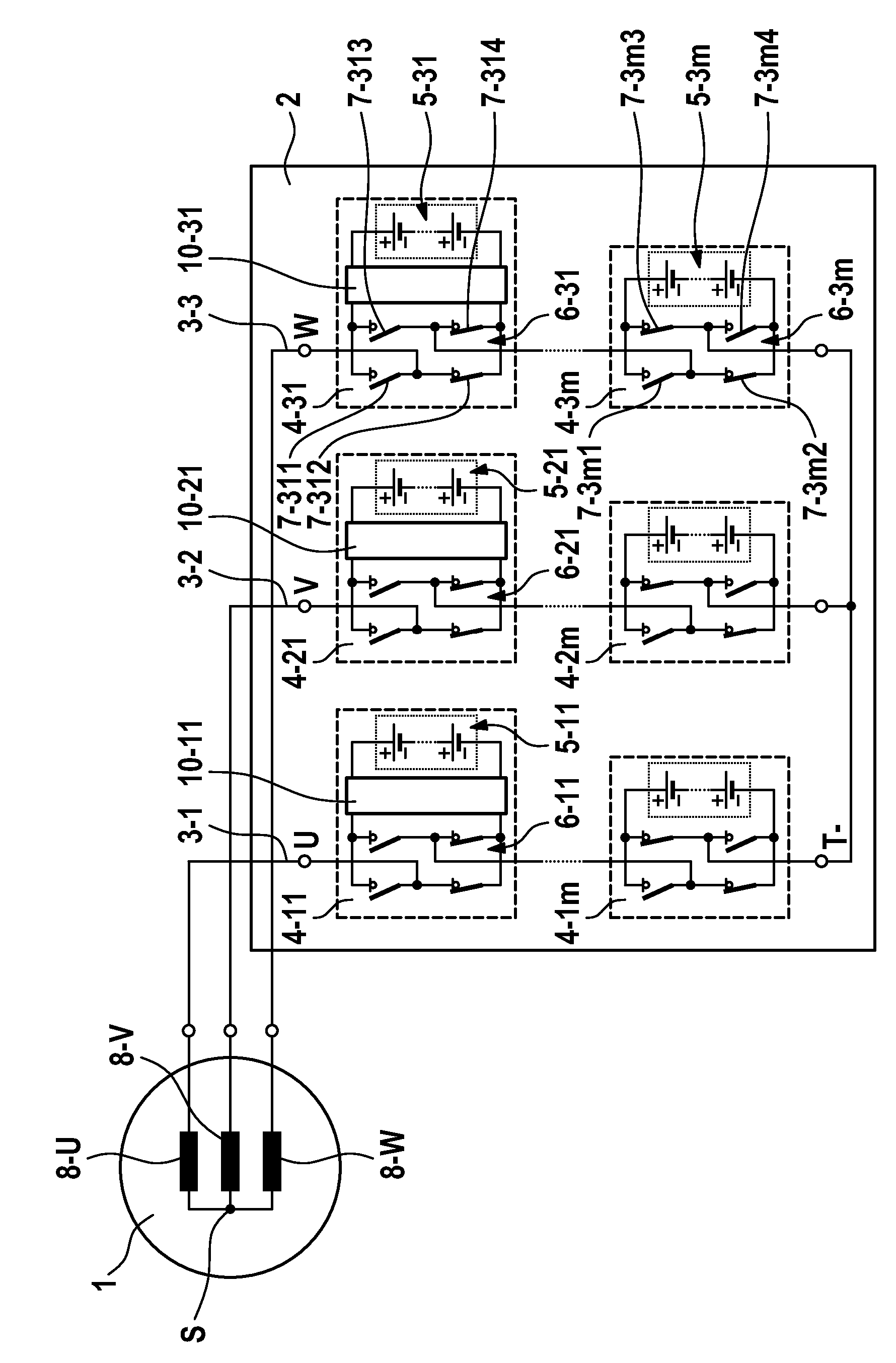

[0026] figure 1 with image 3 A schematic diagram of an implementation form of the controllable energy storage device according to the present invention is shown. The controllable energy storage 2 is connected to the three-phase motor 1. The controllable energy storage 2 comprises three energy supply branches 3-1, 3-2 and 3-3, which are connected on the one hand to a reference potential T- (reference bus), which leads low in the embodiment shown. The electric potential, on the other hand, is connected to each phase U, V, W of the motor 1 respectively. Each of the energy supply branches 3-1, 3-2 and 3-3 has m energy storage modules connected in series 4-11 to 4-1m or 4-21 to 4-2m or 4-31 to 4-3m , Where m≥2. The energy storage module 4 in turn includes a plurality of electric energy storage units connected in series, and the electric energy storage units are only partially equipped with reference numerals 5-11, 5-21, and 5-31 to 5-3 for reasons of clarity. . The energy stora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com