Plastic packaging motor automatic production management system control method

An automatic production, plastic-encapsulated motor technology, applied in electrical program control, transmission system, digital transmission system, etc., can solve the problems of affecting production takt, slow data reading, blockage of command data chain, etc., to save waiting time and production efficiency The effect of improving and reducing the network load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

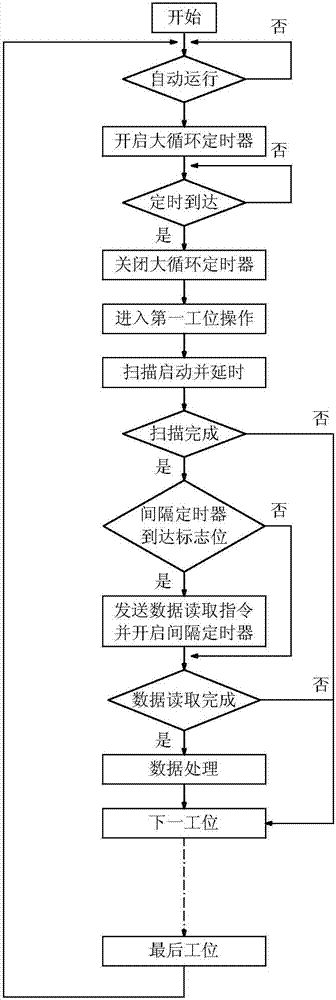

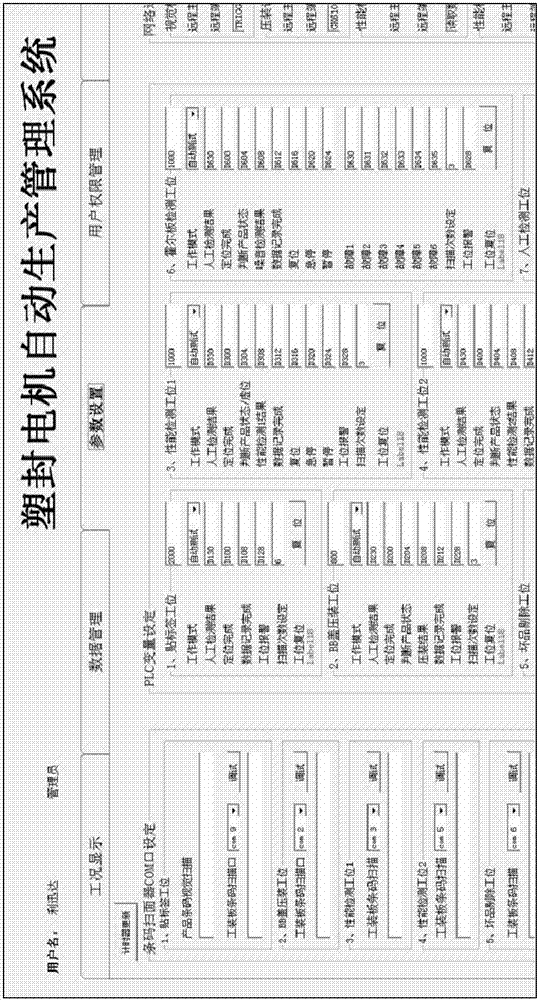

[0027] The present invention will be further described below in conjunction with accompanying drawing, according to figure 1 with figure 2 As shown, the control method of the automatic production management system of plastic-encapsulated motors of the present invention, the involved plastic-encapsulated motors include an electric control module, a time-varying long cycle timer, an interval timer, a scanning gun and a numbered tooling board, wherein the time-varying long-term The cycle timer, interval timer and scanning gun are electrically connected to the electronic control module, and each station is equipped with an interval timer;

[0028] The control method of its automatic production management system comprises the following steps:

[0029] A. Start the automatic production mode and turn on the time-varying long cycle timer;

[0030] B. When the timing of the time-varying long-cycle timer is up, enter the big cycle and turn off the time-varying long-cycle timer;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com