Detection method of spatiotemporal evolution of wall turbulence based on fluorescent fiber tracer

A fluorescent fiber and evolution process technology, applied in the field of laser applications, can solve problems such as harming the health of experimenters, and achieve the effects of comprehensive and rich information, reduced system costs, and simplified structure and control logic.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

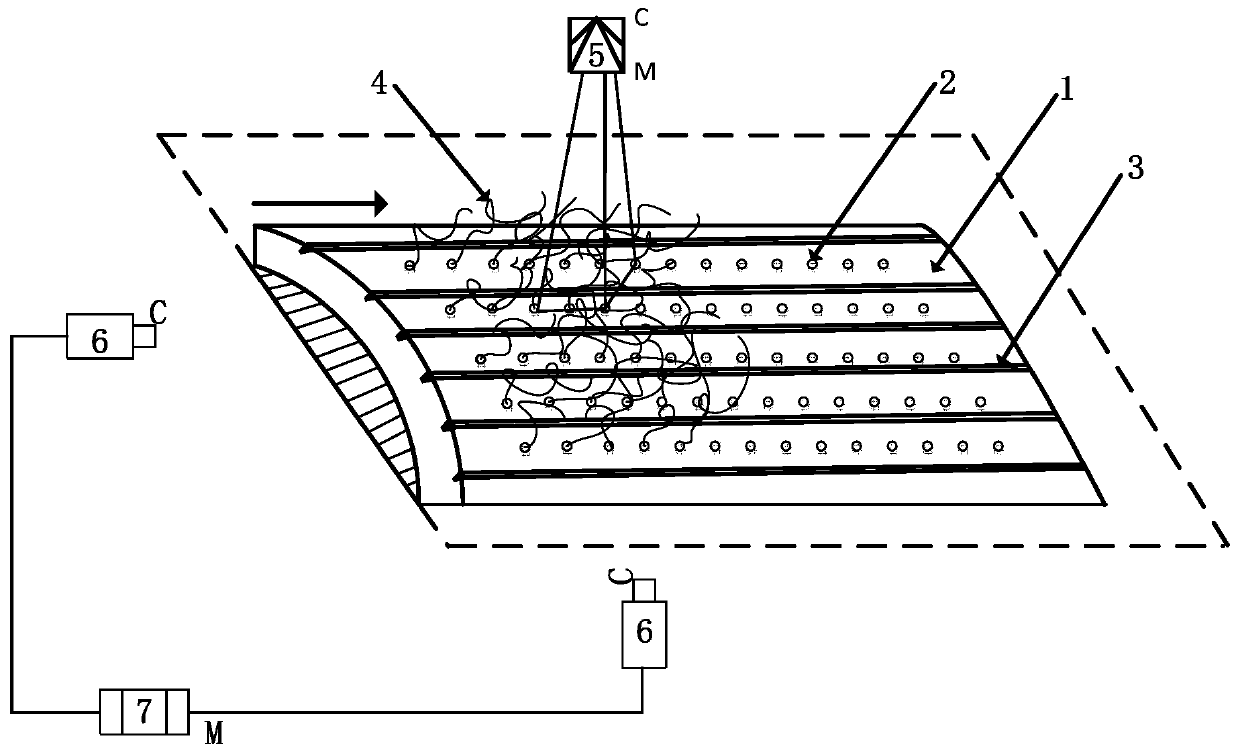

[0035] Such as figure 1 As shown, the present invention provides a method for detecting the spatiotemporal evolution of wall turbulence based on fluorescent fiber tracer, comprising the following steps:

[0036] (1) Prepare the test sample 1; the test sample 1 is a plane, regular curved surface or complex curved surface shell with a certain thickness (1-15mm), and the material can be metal, non-metal or high molecular polymer, and it is required to have better Rigidity and strength, no plastic deformation occurs due to fluid impact during the flow field test; the surface of the test sample 1 is distributed with N micro-through holes 2 (N is a positive integer greater than 0), the micro-through holes 2. The side wall and surface are smooth and burr-free, and the pore diameter is less than 100 μm. Generally, it can be prepared by high-e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com