Multifunctional polyester fiber, preparation method thereof and application

A polyester fiber and multi-functional technology, applied in the field of textile fabrics, can solve the problems of polyester fabrics such as poor air permeability, poor antistatic properties, poor dyeability and anti-pilling properties, and achieve improved hand feel and gloss, and anti-foaming properties. Light-out function, realize the effect of wet body alert

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

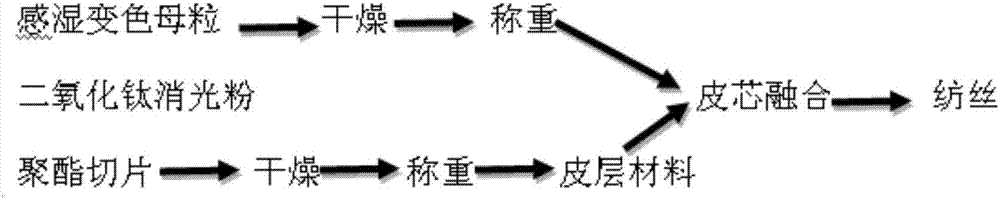

[0027] Correspondingly, the invention provides a kind of preparation method of multifunctional polyester fiber, comprises the following steps:

[0028] Provide PET masterbatch containing humidity-changing liquid crystal material and titanium dioxide;

[0029] Melt-spinning the PET masterbatch and polyester chips to obtain a multifunctional polyester fiber including a skin layer and a core layer, the skin layer is a polyester layer, and the core layer is a PET material containing a wet color-changing liquid crystal material and titanium dioxide. Floor.

[0030] The preparation method provided by the present invention uses textile polymer raw materials as the base material to prepare multifunctional polyester fibers with both anti-light and wet body alert functions. This fiber can be used in various fields such as clothing and home textiles. It can bring practicality such as privacy, security and comfort to the wearer, and can change colors to add interest and fashion.

[0031...

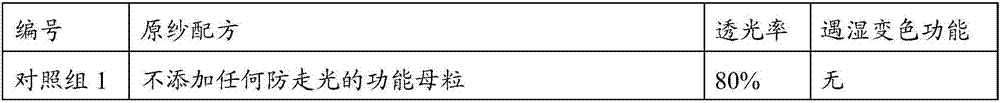

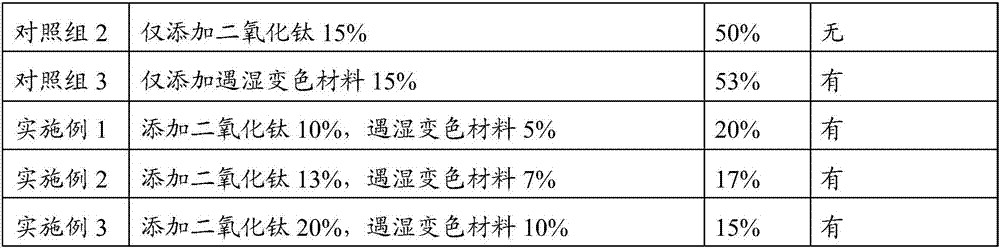

Embodiment 1

[0044] 75D / 72F polyester fiber with anti-slip and wet body alert and its preparation method and application.

[0045] (1) Preparation of PET masterbatch containing wet color-changing liquid crystal material and titanium dioxide: the wet color-changing liquid crystal material (5%), titanium dioxide (10%), dispersant (5%), thermal stabilizer (2%), light Stabilizer (2%), antioxidant (2%) and polyester FDY (74%) slices are mixed; Adopt the method for in-situ polymerization to obtain PET masterbatch slices, it carries out esterification reaction 2h under 0.2MPa through the first step, In the second step, pre-condensation polymerization is carried out at 260°C under high temperature and normal pressure for 1 hour, and in the third step, the polycondensation reaction is carried out at 270°C under vacuum conditions for 1 hour to obtain PET masterbatch chips.

[0046] (2) Weigh 400g of PET masterbatch and cortex polyester, dry them, melt them through a single-screw extruder respectivel...

Embodiment 2

[0050] 80D / 72F polyester fiber with both anti-light and wet body alertness and its preparation method and application.

[0051] (1) Preparation of PET masterbatch containing wet color-changing liquid crystal material and titanium dioxide: the wet color-changing liquid crystal material (7%), titanium dioxide (13%), dispersant (6%), heat stabilizer (4%), light Stabilizer (7%), antioxidant (7%) and polyester FDY (56%) slices are mixed; Adopt the method for in-situ polymerization to obtain PET masterbatch slices, it carries out esterification reaction 3h under 0.4MPa by the first step, In the second step, pre-condensation polymerization is carried out at 270°C under high temperature and normal pressure for 2 hours, and in the third step, the polycondensation reaction is carried out at 270°C under vacuum for 2 hours to obtain PET masterbatch chips.

[0052] (2) Weigh 500g of PET masterbatch and cortex polyester, dry them, melt them through a single-screw extruder respectively, then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average length | aaaaa | aaaaa |

| Average linear density | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com