Method for preparing tungsten diselenide semiconductor film on FTO substrate and application of method

A technology of tungsten diselenide and semiconductor, which is applied in the direction of photosensitive equipment, liquid chemical plating, coating, etc., can solve the problem of less film, and achieve the effect of good crystallization, uniform phase and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

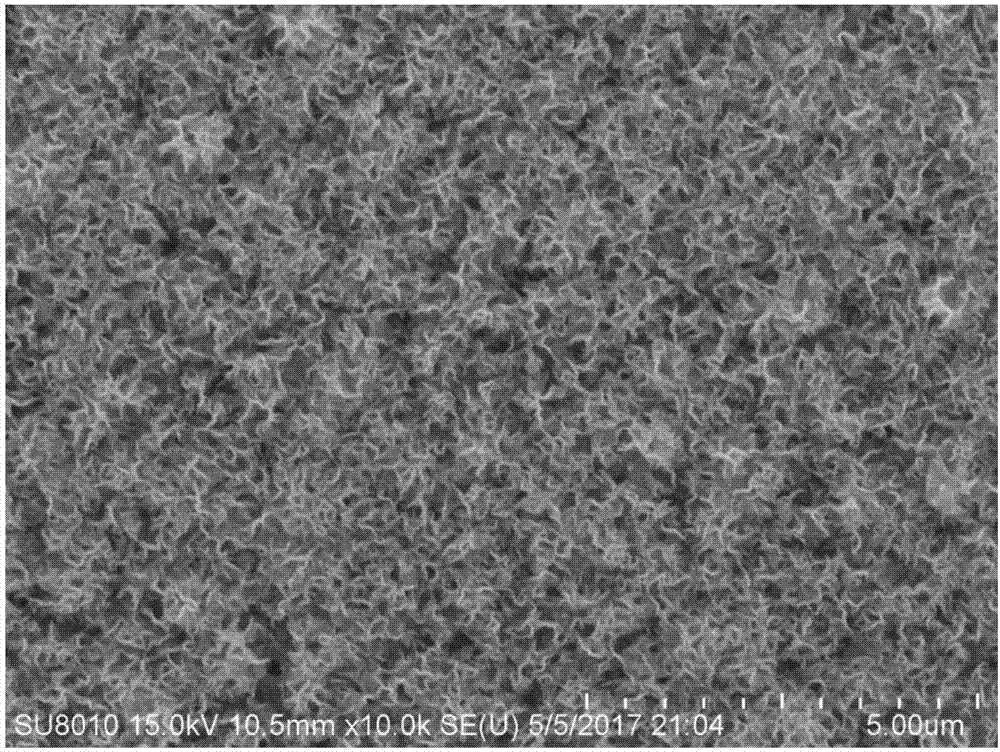

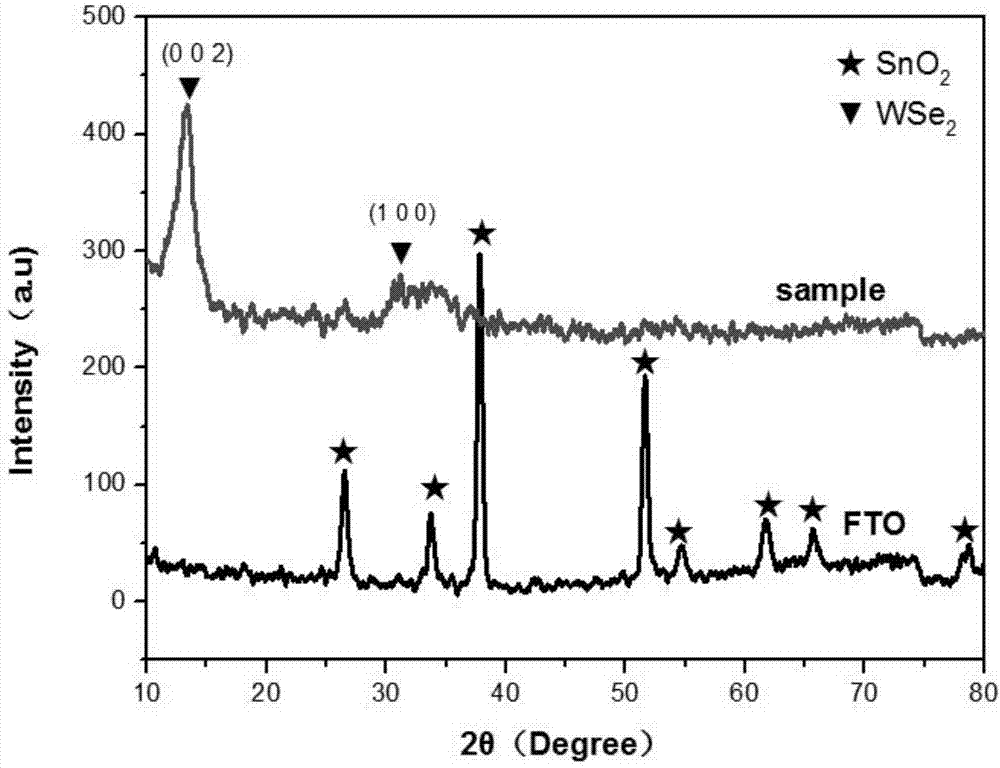

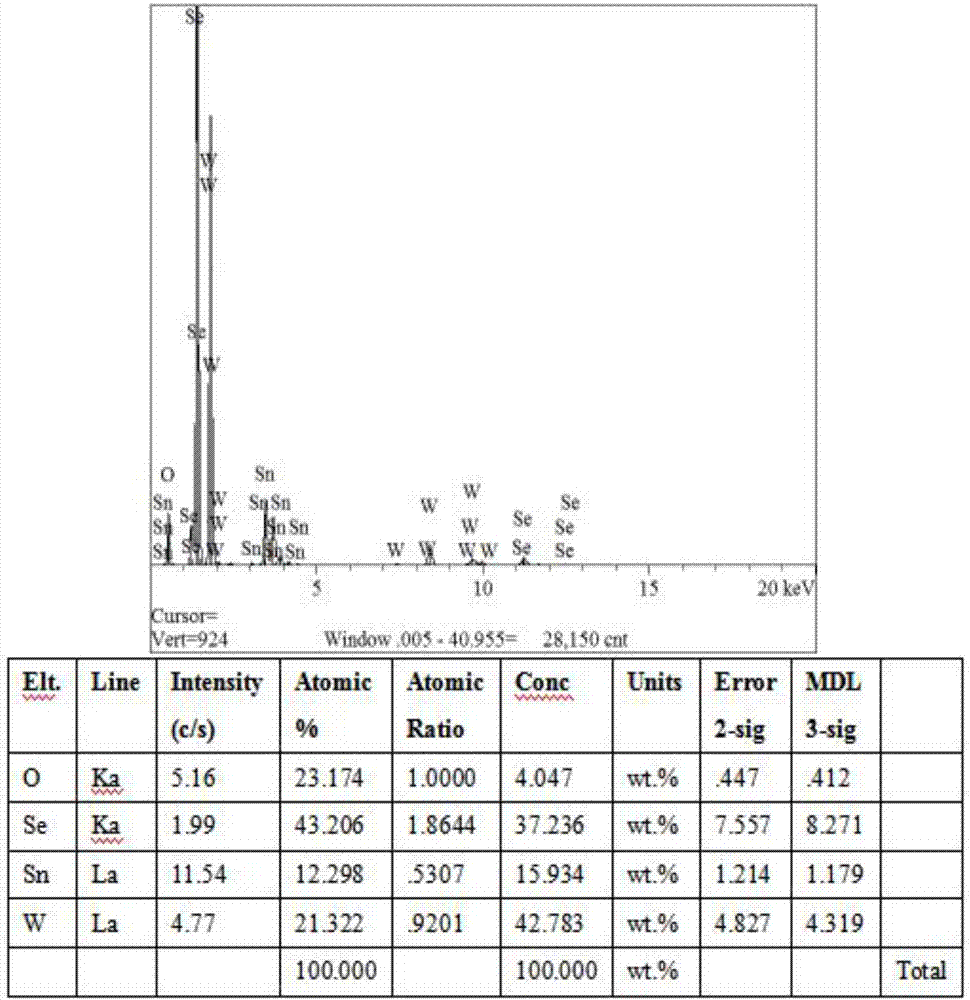

[0043] A method for preparing a tungsten diselenide semiconductor thin film on an FTO substrate, which specifically includes:

[0044] Cleaning steps for FTO conductive glass: place the FTO glass on the cleaning rack, then put it into a beaker, and use acetone, absolute ethanol, and distilled water to clean it ultrasonically for 5 minutes. After cleaning, use clean tweezers to remove the glass piece from the rack. Take it out and dry it with a lint-free cloth;

[0045]After adding 0.20g sodium borohydride into 60ml of DMF, use magnetic stirring until fully dissolved; then, after adding 8.2mmol selenium powder and 4mmol sodium tungstate in sequence, use magnetic stirring for 1 hour until fully dissolved, mix evenly to obtain the reaction precursor liquid;

[0046] Put the cleaned FTO conductive glass into a 100ml clean reactor lining, with the conductive side leaning against the inner wall of the reactor inner substrate; then slowly pour the reaction precursor solution into th...

no. 2 Embodiment

[0049] A method for preparing a tungsten diselenide semiconductor thin film on an FTO substrate, which specifically includes:

[0050] Cleaning steps for FTO conductive glass: place the FTO glass on the cleaning rack, then put it into a beaker, and use acetone, absolute ethanol, and distilled water to clean it ultrasonically for 5 minutes. After cleaning, use clean tweezers to remove the glass piece from the rack. Take it out and dry it with a lint-free cloth;

[0051] After adding 0.20g sodium borohydride into 60ml of DMF, use magnetic stirring until fully dissolved; then, after adding 8.2mmol selenium powder and 4mmol sodium tungstate in sequence, use magnetic stirring for 1 hour until fully dissolved, mix evenly to obtain the reaction precursor liquid;

[0052] Put the cleaned FTO conductive glass into a 100ml clean reactor lining, with the conductive side leaning against the inner wall of the reactor inner substrate; then slowly pour the reaction precursor solution into t...

no. 3 Embodiment

[0055] A method for preparing a tungsten diselenide semiconductor thin film on an FTO substrate, which specifically includes:

[0056] Cleaning steps for FTO conductive glass: place the FTO glass on the cleaning rack, then put it into a beaker, and use acetone, absolute ethanol, and distilled water to clean it ultrasonically for 5 minutes. After cleaning, use clean tweezers to remove the glass piece from the rack. Take it out and dry it with a lint-free cloth;

[0057] After adding 0.22g of sodium borohydride into 60ml of DMF, use magnetic stirring until it is fully dissolved; then, after adding 8.4mmol of selenium powder and 4mmol of sodium tungstate in sequence, use magnetic stirring for 1 hour until it is fully dissolved, and mix evenly to obtain a reaction precursor liquid;

[0058] Put the cleaned FTO conductive glass into a 100ml clean reactor lining, with the conductive side leaning against the inner wall of the reactor inner substrate; then slowly pour the reaction pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com