A vertical mechanical model material thin layer cutting device

A technology of model materials and cutting devices, which is applied in the field of multi-interlayered rock mass simulation tests, can solve the problems of uneven surface of thin layers, waste of artificial and material resources, and restrictions on applicable conditions, and achieve saving of manpower and material resources, easy installation, thin layer good homogeneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing, the present invention is described in further detail:

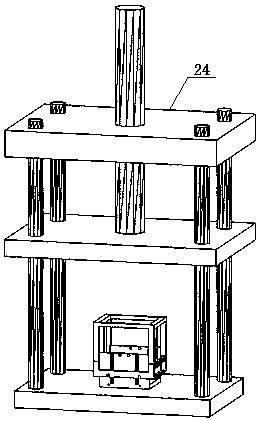

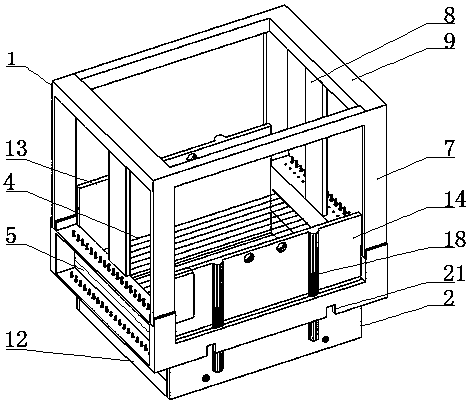

[0027] as attached Figure 1-5 As shown, a vertical mechanical model material thin-layer cutting device includes a pressure testing machine 24, a vertical wire cutting frame 1, a material box 2, a pressing plate 3 and a plastic steel wire 4.

[0028] as attached Figure 4 As shown, the material box 2 is made up of five detachable plates, including the left side wall 13, the right side wall 14, the front wall 15, the rear wall 16 and the bottom plate 12 of the material box, which are connected to each other by bolts 19; the material box front wall 15 And rear wall 16 outer sides are respectively provided with two vertical slide rails 18.

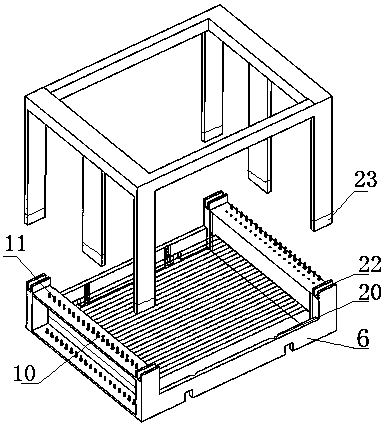

[0029] as attached figure 2 , 3 As shown, the vertical wire cutting frame 1 is welded by two channel steels 5, two side steel plates 6, four column legs 7, two supporting legs 8 and four beams 9; The parallel plastic steel wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com