Method for improving adhesive force of unsaturated polyester resin putty and double-component waterborne epoxy primer

A technology of polyester resin and water-based epoxy, which is applied to the surface coating liquid device, pretreatment surface, coating, etc., and can solve the problems of adhesion not reaching level 3, accelerated styrene volatilization, and high viscosity of putty , to achieve the effect of improving coating quality, saving coating cost and improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

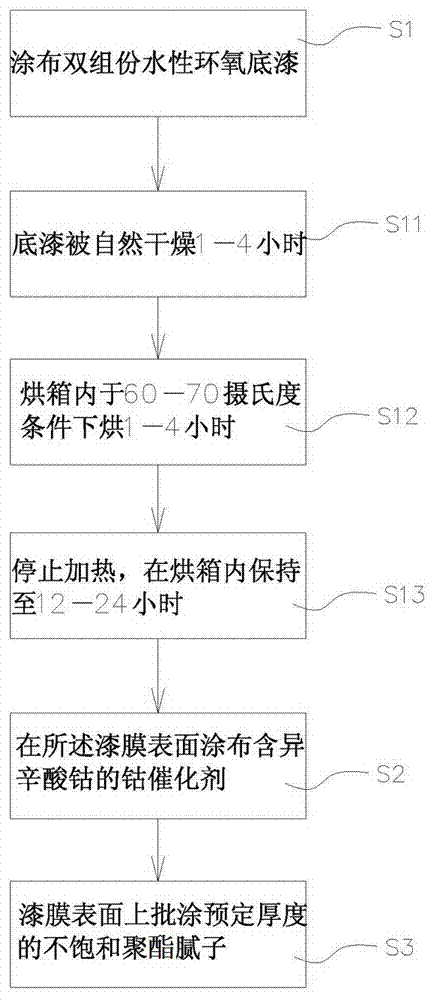

[0020] See figure 1 , figure 1 Disclosed is a method for enhancing the adhesion of unsaturated polyester resin putty and two-component water-based epoxy primer, comprising the following steps,

[0021] S1. Apply a two-component water-based epoxy primer on the substrate, and dry the primer to form a paint film; the substrate will be treated in the present invention, including but not limited to various metal plates and profiles , such as steel, alloy materials, etc., but the materials that need to be leveled can be regarded as base materials; non-metallic plates and profiles, such as wood boards, stair handrails, etc.; and surface treatment of trains, motor vehicles, automobiles, and construction machinery; in the present invention The two-component water-based epoxy primer includes: Type I water-based epoxy resin system, which is composed of low-molecular-weight liquid epoxy resin and water-based epoxy curing agent. The epoxy resin is mixed and emulsified by the water-based e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com