Lithium battery and power utilization apparatus

A lithium battery and electrolyte technology, applied in the field of lithium batteries and electrical devices, can solve the problems of poor cycle performance and general conductivity, and achieve the effects of high conductivity, good cycle performance and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

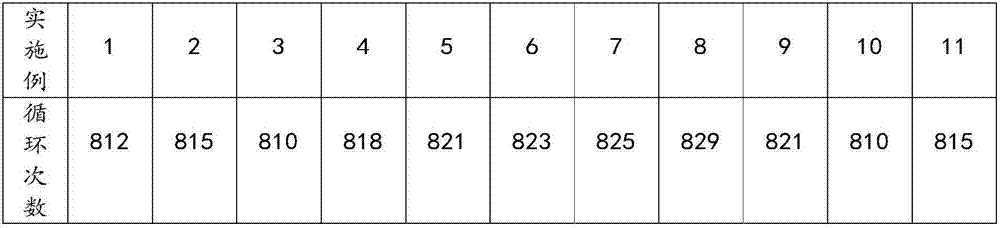

Embodiment 1

[0032] Weigh 48g of lithium hexafluorophosphate, 30g of lithium dioxalate borate, 0.1g of carbodiimide, 0.3g of anisole, 0.1g of dimethoxy substituted benzene in the ortho position, 0.1g of tris(2-chloroethyl)phosphate, carbonic acid 2g of diethyl ester, 1.5g of ethylene carbonate, and 0.5g of acrylamide are used to make an electrolyte, and the electrolyte is further made into a lithium battery, using carbon as the negative electrode, lithium iron phosphate coated with a graphite layer as the positive electrode and poly The diaphragm made of ethylene, and finally measure the conductivity and cycle times of the lithium battery, and record them in Table 1 and Table 2 respectively.

Embodiment 2

[0034] Weigh 60 g of lithium hexafluorophosphate, 35 g of lithium dioxalate borate, 1.2 g of carbodiimide, 2 g of anisole, 1 g of para-dimethoxy substituted benzene, 4 g of tris(2-chloroethyl) phosphate, and dimethyl carbonate 8g, 7g of ethylene carbonate, and 0.7g of acrylamide were used to make an electrolyte, and the electrolyte was further made into a lithium battery, using carbon as the negative electrode, lithium iron phosphate coated with a graphite layer as the positive electrode, and a diaphragm made of polyethylene , and finally measure the conductivity and the number of cycles of the lithium battery, and record them in Table 1 and Table 2, respectively.

Embodiment 3

[0036]Weigh 50 g of lithium hexafluorophosphate, 31 g of lithium dioxalate borate, 0.4 g of carbodiimide, 0.5 g of monochloromethane, 0.2 g of para-dimethoxy substituted benzene, 0.5 g of tris(dibromopropylene) phosphate, methyl ethyl carbonate 2g of ester, 2g of ethylene carbonate, and 0.55g of acrylamide are used to make an electrolyte, and the electrolyte is further made into a lithium battery, using carbon as the negative electrode, lithium iron phosphate coated with a graphite layer as the positive electrode, and polyethylene. Diaphragm, and finally measure the conductivity and number of cycles of the lithium battery, and record them in Table 1 and Table 2, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com