Outdoor modular refrigeration module and its installation method

A modular and cooling module technology, applied in the field of computer room or data center infrastructure, can solve the problems of long construction time, long construction time, substandard project quality, etc., so as to reduce the on-site construction workload and shorten the air flow distance. , the effect of reducing assembly complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

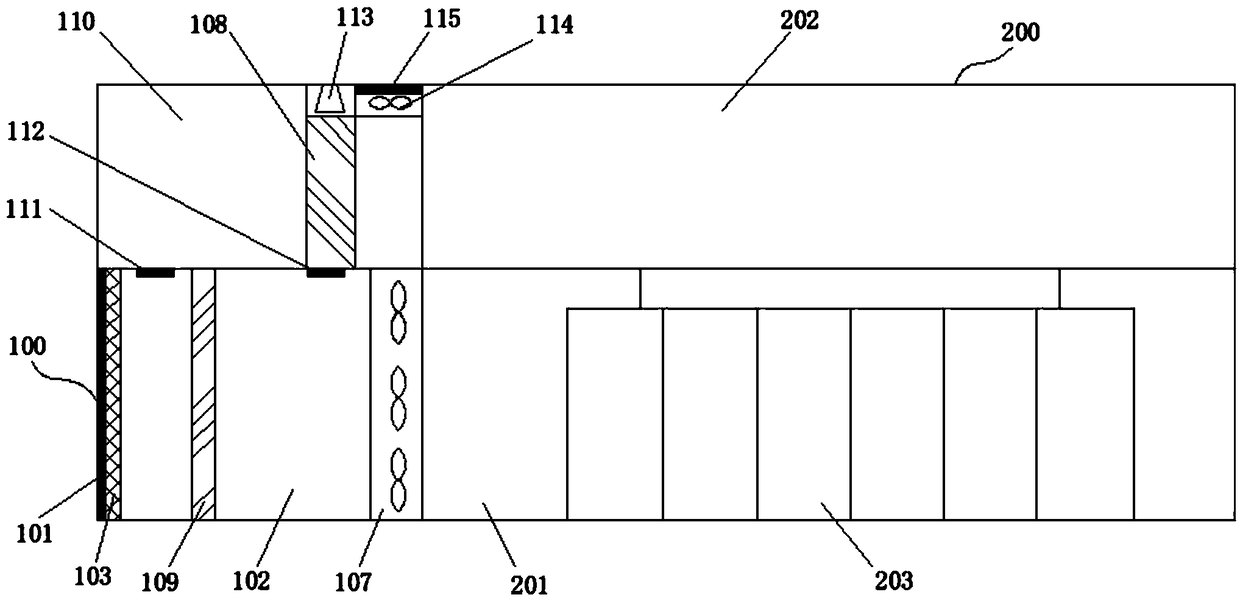

[0080] figure 2 It is a working principle diagram of the direct fresh air cooling mode of the present invention. The direct fresh air cooling mode cools the cabinet 203 by introducing outdoor fresh air into the cold aisle 201 , and the heat exchanger and refrigeration unit do not work in this mode. The direct fresh air cooling mode is suitable for use when the outdoor temperature is low (generally 10-25°C) and the air quality is good, such as winter in low-latitude areas or high-latitude areas.

[0081] In the direct fresh air cooling mode, the direct air intake damper 101 and the exhaust air damper 115 remain open, the wind wall fan array and exhaust fan 114 work, and the indirect air intake damper 104, the first return air damper 111 and the second The return air valves 112 are all kept closed, and the heat exchanger, the spraying device 112, and the refrigerating unit are not started. Its working process is as follows: the outdoor cold air enters the air inlet chamber 10...

Embodiment 2

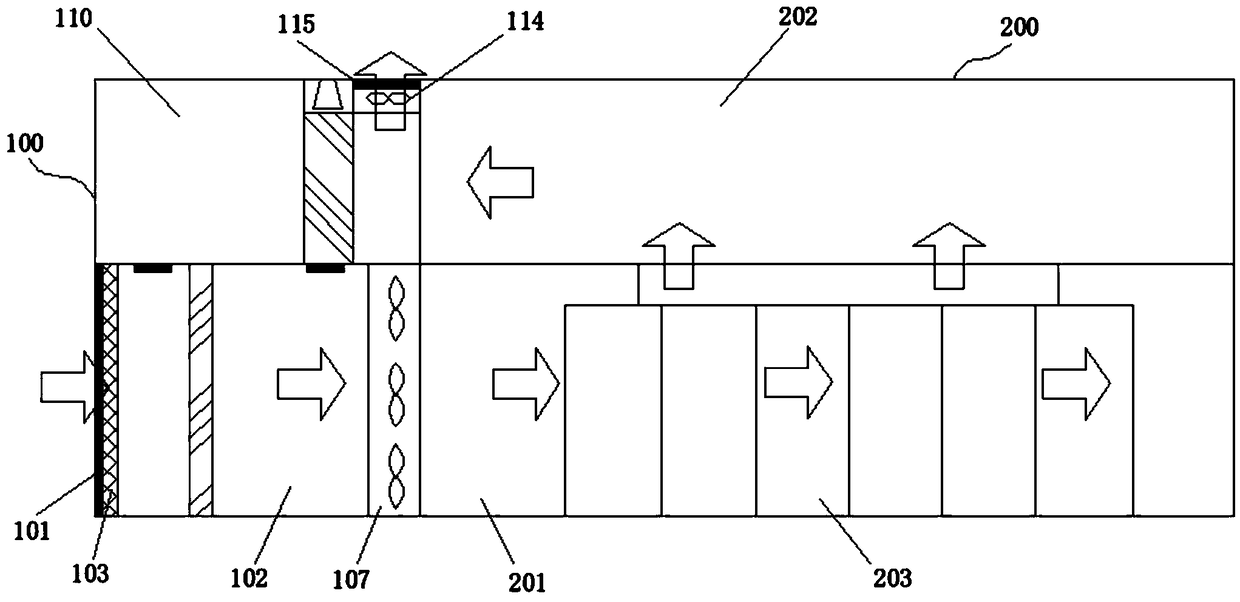

[0084] image 3 It is a working principle diagram of an indirect fresh air cooling mode in the present invention. In this indirect fresh air cooling mode, the outdoor low-temperature air and the hot air in the hot aisle 202 are introduced into the heat exchanger, so that the hot air and the low-temperature air perform heat exchange in the heat exchanger, and the hot air becomes cold air after being cooled, and then The cold air is sent back to the cold aisle 201 of the cabinet module to cool the cabinet 203 . This indirect fresh air cooling mode is suitable for use under conditions where the outdoor temperature is low (generally 10-25°C) but the air quality is not up to standard, such as foggy days.

[0085]In the indirect fresh air cooling mode, the indirect air intake valve 104 and the second return air valve 112 are kept open, the wind wall fan array and the heat exchanger work, and the direct air intake valve 101 and the first return air valve 111 All remain closed, and ...

Embodiment 3

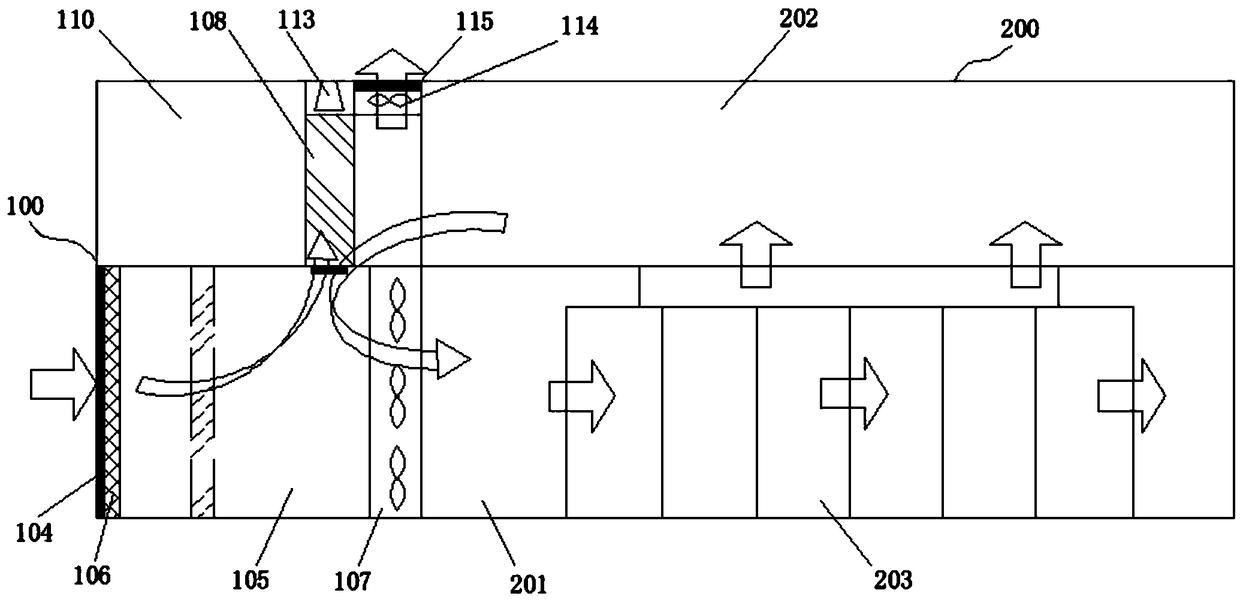

[0089] This embodiment provides another indirect fresh air cooling mode. In this indirect fresh air cooling mode, the outdoor low-temperature air and the hot air in the hot aisle 202 are introduced into the heat exchanger, so that the hot air and the low-temperature air perform heat exchange in the heat exchanger. At the same time, the hot air is quickly turned into cold air by water spraying, and then the cold air is sent back to the cold aisle 201 of the cabinet module, so as to cool the cabinet 203 . This indirect fresh air cooling mode is suitable for use when the outdoor temperature is low (generally 20-30°C) but the air quality is not up to standard.

[0090] In the indirect fresh air cooling mode, the indirect air intake valve 104 and the second return air valve 112 are kept open, the wind wall fan array, the spray device 113 and the heat exchanger 108 work, and the direct air intake valve 101, the second return air valve The primary return air dampers 111 are all kept ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com