Ultrahigh-hardness ultrahigh-strength special steel and production method thereof

A technology of ultra-high strength and hardness, which is applied in the field of ultra-high hardness and ultra-high-strength special steel and its production, and can solve the problems of high raw material cost and difficult machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

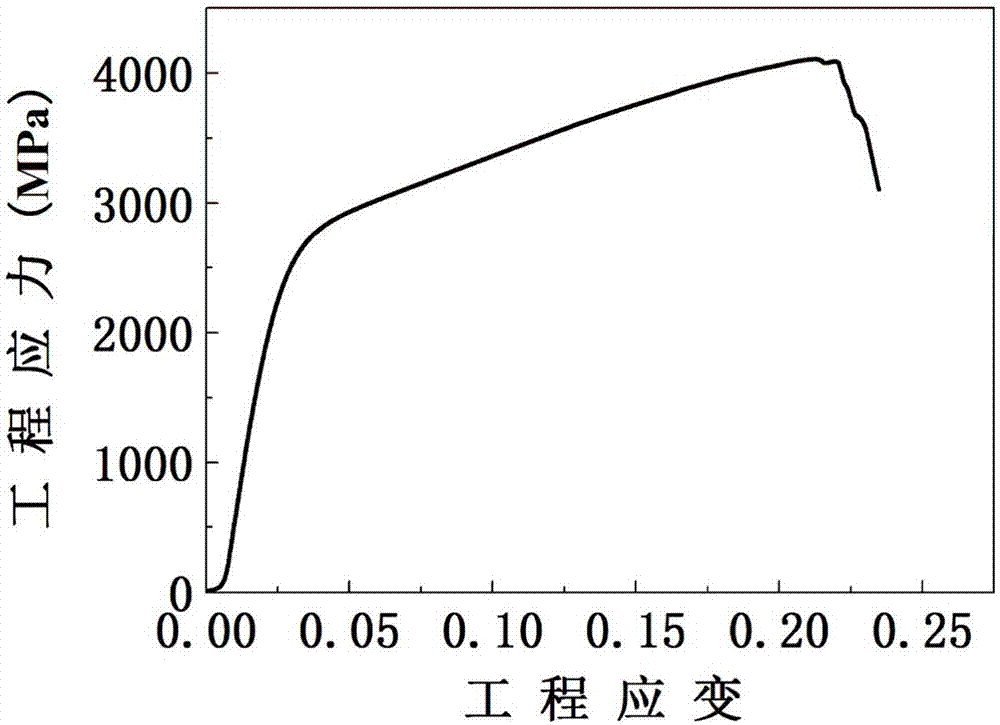

Image

Examples

Embodiment 1

[0018] The ultra-high hardness and ultra-high strength special steel in this embodiment, wherein: the composition expression of the special steel is C a Si b mn c m d Fe e , wherein M is composed of the following alloying elements in weight percentage: Cr 30%, Mo / 20%, V 20%, Nb 10%, Cu 10% and Al 10%, a, b, c, d, e are weight percentages, And a+b+c+d+e=100%, where a=1.65%, b=1.5%, c=2.0%, d=5.0%.

[0019] A method for producing the above-mentioned ultra-high hardness and ultra-high strength special steel, which consists of the following steps:

[0020] 1) Raw steel scrap, ferromanganese, ferrochrome, ferromolybdenum, ferrovanadium, ferroniobium, copper, and aluminum are batched into 150kg according to the weight percentage of the special steel components, wherein the content of silicon is adjusted by rare earth ferrosilicon, and the content of carbon Adjusted by carburant;

[0021] 2) Place part of the scrap steel in the ingredients in step 1) in an intermediate frequenc...

Embodiment 2

[0027] The ultra-high hardness and ultra-high strength special steel in this embodiment, wherein: the composition expression of the special steel is C a Si b mn c m d Fe e , wherein M is composed of the following alloy elements in weight percentage: Cr35%, Ti25%, V20%, W10% and Al10%, a, b, c, d, e are weight percentages, and a+b+c+d+ e=100%, where a=1.8%, b=1.0%, c=1.5%, d=6.0%, and the rest is e.

[0028] A method for producing the above-mentioned ultra-high hardness and ultra-high strength special steel, which consists of the following steps:

[0029] 1) Mix scrap steel, ferromanganese, ferrochrome, ferrovanadium, ferrotungsten, titanium, and aluminum raw materials according to the weight percentage of the special steel components to 150kg, wherein the content of silicon is adjusted by rare earth ferrosilicon, and the content of carbon is adjusted by carburization dosage adjustment;

[0030] 2) Place part of the steel scrap in the batching in step 1) in an intermediat...

Embodiment 3

[0036] The ultra-high hardness and ultra-high strength special steel in this embodiment, wherein: the composition expression of the special steel is C a Si b mn c m d Fe e, where M is composed of the following alloy elements in weight percentage: Cr 30%, Mo 20%, V 20%, W10%, Ti 10%, Cu 5% and Al 5%, a, b, c, d, e are Percentage by weight, and a+b+c+d+e=100%, wherein a=1.95%, b=0.6%, c=0.6%, d=7.0%, and the rest is e.

[0037] A method for producing the above-mentioned ultra-high hardness and ultra-high strength special steel, which consists of the following steps:

[0038] 1) Scrap steel, ferromanganese, ferrochrome, ferromolybdenum, ferrovanadium, ferrotungsten, titanium, copper, and aluminum are batched into 150kg according to the weight percentage of the special steel components, wherein the content of silicon is adjusted by rare earth ferrosilicon, carbon The content is adjusted by carburant;

[0039] 2) Place part of the steel scrap in the batching in step 1) in an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com