A preparation method of CVD diamond micro milling cutter based on laser and precision sharpening

A diamond and precision grinding machine technology, used in laser welding equipment, milling cutters, milling machine equipment, etc., can solve the problems of long processing time, no free cutting surface, reduced tool strength, etc., to achieve high surface quality and sharp tool cutting edges. , the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

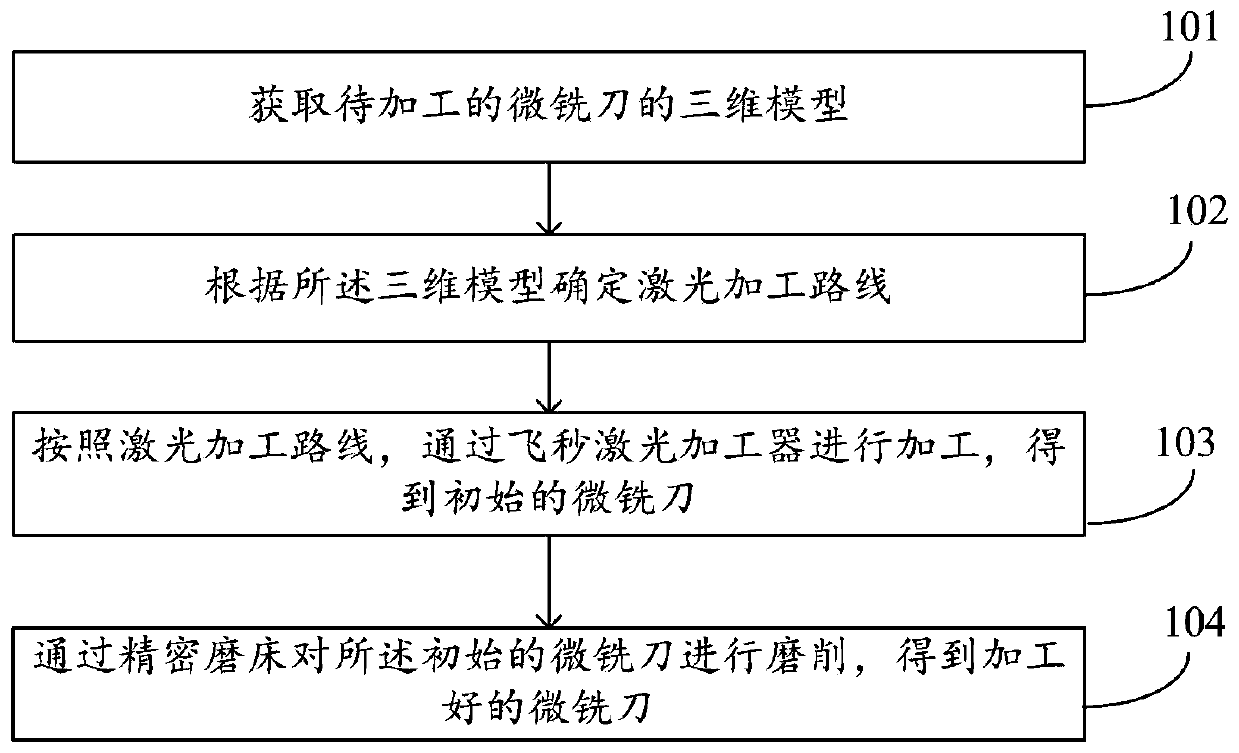

[0052] like figure 1 Shown, a kind of CVD diamond micro milling cutter preparation method based on laser and precision sharpening, described preparation method comprises:

[0053] Step 101: Obtain a three-dimensional model of the micro milling cutter to be processed. Design the 3D model of the micro-milling cutter to be processed, and carry out modeling, modal analysis and milling simulation on it.

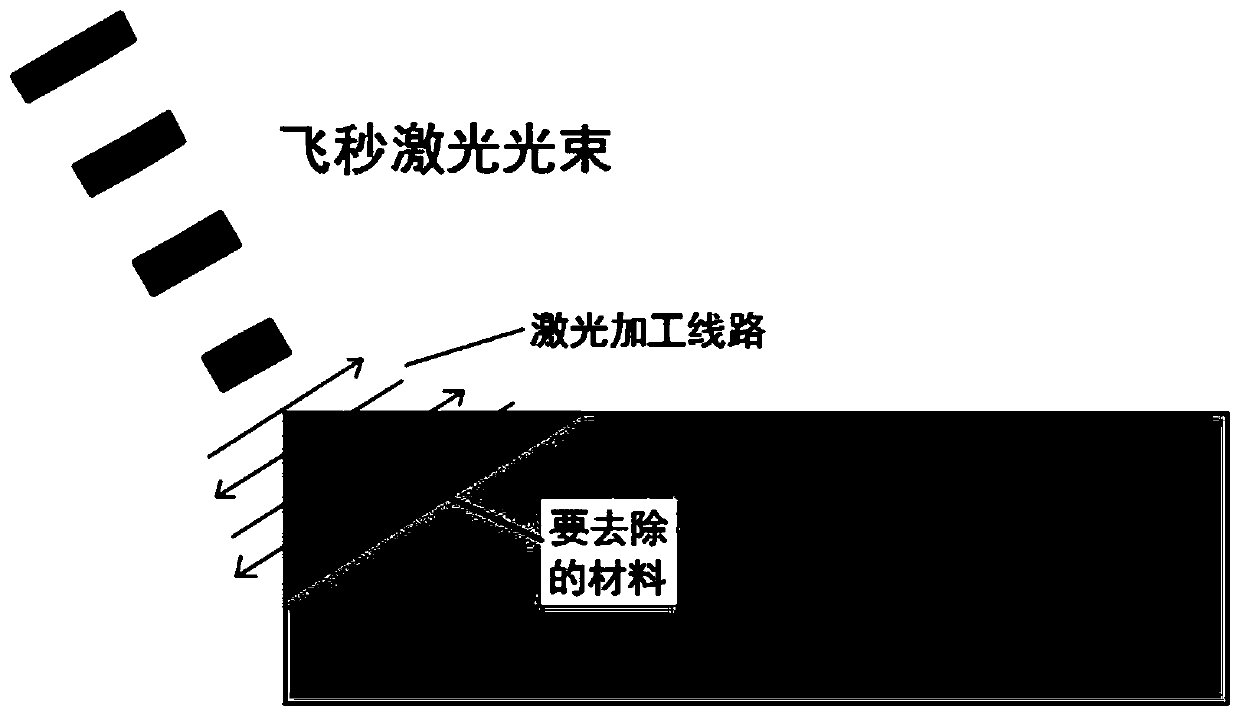

[0054] Step 102: Determine the laser processing route according to the three-dimensional model. Specifically, determine the tool shape and tool parameters of the micro-milling cutter to be processed according to the three-dimensional model, and the tool parameters include tool rake angle, tool relief angle, and laser processing routes such as figure 2 shown.

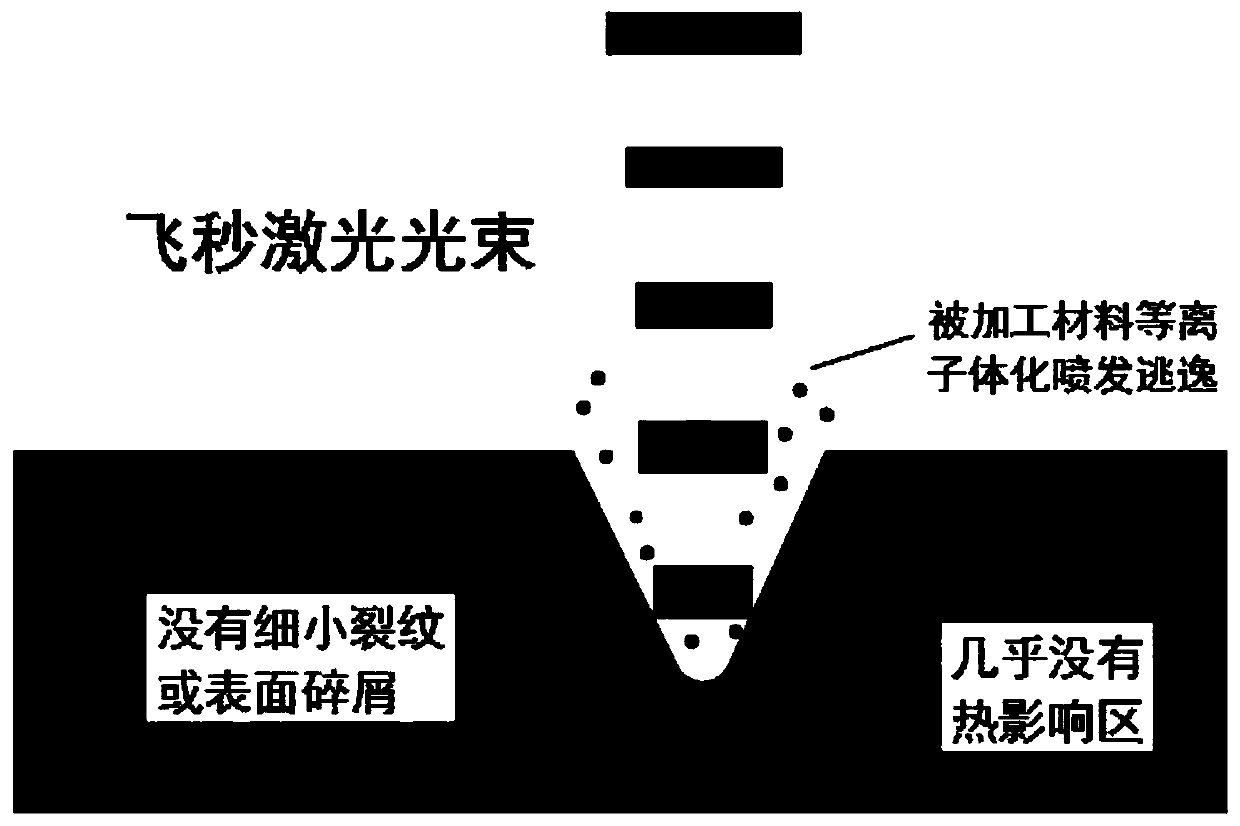

[0055] Step 103: According to the laser processing route, process with a femtosecond laser processor to obtain an initial micro milling cutter. Specifically: extract the dimensional characteristics of the micro-milling ...

Embodiment 1

[0059] The cutter head material is selected as CVD diamond thick film, and the effective size of the CVD diamond cutter head is: length 0.9mm, width 0.6mm, thickness 0.45mm, combined with the CVD diamond micro-milling cutter preparation method based on laser and precision sharpening proposed by the present invention For further clarification:

[0060] (1) Design the three-dimensional model of the micro-milling cutter to be processed, and carry out modeling, modal analysis and milling simulation on it, and select the appropriate tool parameters: the diameter of the tool handle is 4mm, the length of the blade is 1mm, and the diameter of the blade is 0.8mm , the rake angle is 0°, the relief angle is 6°, and the laser processing circuit diagram is designed according to the shape of the tool.

[0061] (2) Clamp the CVD diamond blank on the femtosecond laser processor, adjust the clamping angles to 0° and 6° respectively in the processing of the rake angle and back angle, and import...

Embodiment 2

[0065] Use method of the present invention to also can process the CVD diamond micro-milling cutter of large length-to-diameter ratio, the cutter head material is selected as CVD diamond thick film, and the effective size of CVD diamond cutter head is: long 1.5mm, wide 0.5mm, thick 0.55mm, Combining the CVD diamond micro-milling cutter preparation method based on laser and precision sharpening proposed by the present invention, the CVD diamond micro-milling cutter with large aspect ratio can increase the effective cutting edge length of the micro-milling cutter, and can be better applied to Workpieces with high aspect ratio structures are being processed. Specific steps are as follows:

[0066] (1) Design the three-dimensional model of the micro-milling cutter to be processed, and carry out modeling, modal analysis and milling simulation on it, and select the appropriate tool parameters as follows: shank diameter 4mm, effective cutting edge length 2.5mm, cutting edge The diam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com