High temperature resistant and corrosion resistant coating for surface of distribution box and preparation method of high temperature resistant and corrosion resistant coating

A high-temperature-resistant and corrosion-resistant technology, applied in the field of high-temperature-resistant and corrosion-resistant coatings and its preparation, can solve the problems of poor corrosion resistance of ordinary coatings, shorten the service life of distribution boxes, and corrosion of the box body, and achieve good sealing , The coating film is dense and neat, ensuring the effect of normal work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

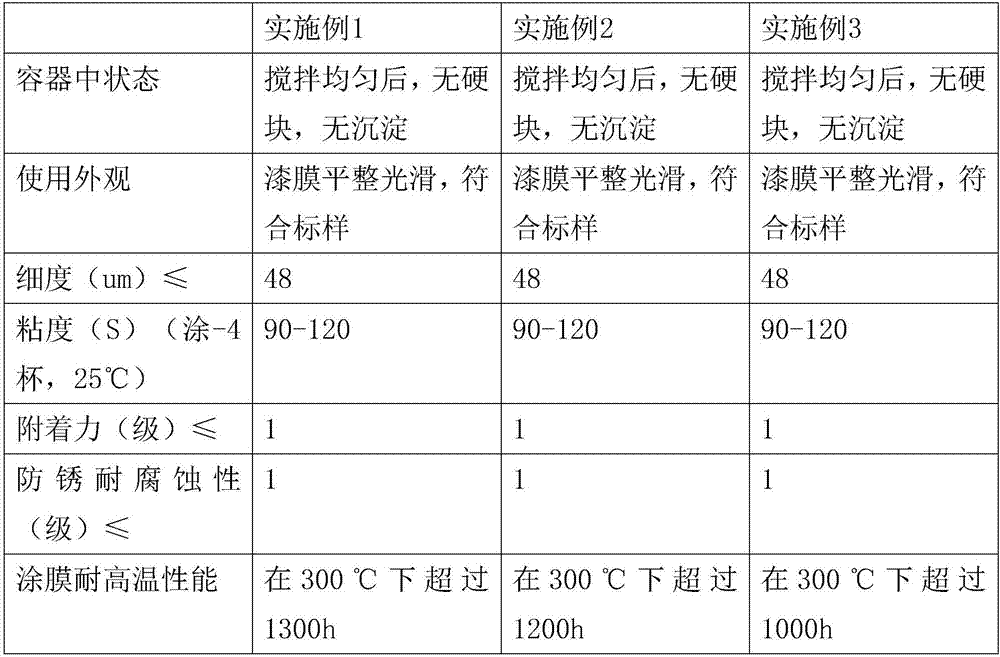

Examples

Embodiment 1

[0019] (1) Weigh each raw material by the following parts by weight: 75 parts of epoxy resin modified silicone resin, 15 parts of xylene, 15 parts of propylene glycol, 7 parts of zinc naphthenate, 5 parts of tri-n-butyl tin chloride, petroleum 3 parts of barium sulfonate, 10 parts of kerosene, 8 parts of lauroyl diethanolamine, 6 parts of p-methylaniline, 6 parts of zinc powder, 5 parts of silicon nitride, 7 parts of chromium carbide, 8 parts of aluminized glass beads, carbon dioxide 12 parts of silicon, 6 parts of aluminum oxide, 5 parts of calcium sulfate whisker powder, 8 parts of polytetrafluoroethylene, 8 parts of aloe juice, 12 parts of mica powder, 10 parts of graphite, 3 parts of cardanol modified amine curing agent, 2 parts of leveling agent, 2 parts of defoamer;

[0020] (2) Add epoxy resin modified silicone resin, xylene, and propylene glycol into the reaction kettle, and stir for 3-5 minutes at a speed of 550-650 rpm;

Embodiment 2

[0025] (1) Weigh each raw material by the following parts by weight: 50 parts of epoxy resin modified silicone resin, 20 parts of xylene, 15 parts of propylene glycol, 8 parts of zinc naphthenate, 5 parts of tri-n-butyl tin chloride, petroleum 3 parts of barium sulfonate, 10 parts of kerosene, 6 parts of lauroyl diethanolamine, 3 parts of p-methylaniline, 5 parts of zinc powder, 6 parts of silicon nitride, 7 parts of chromium carbide, 10 parts of aluminized glass beads, carbon dioxide 12 parts of silicon, 6 parts of aluminum oxide, 4 parts of calcium sulfate whisker powder, 6 parts of polytetrafluoroethylene, 6 parts of aloe juice, 18 parts of silica powder, 12 parts of manganese dioxide, 5 parts of cardanol modified amine curing agent 1 part, 1 part of leveling agent, 2 parts of defoamer;

[0026] (2) Add epoxy resin modified silicone resin, xylene, and propylene glycol into the reaction kettle, and stir for 3-5 minutes at a speed of 550-650 rpm;

[0027] (3) Zinc naphthenat...

Embodiment 3

[0031] (1) Weigh each raw material according to the following parts by weight: 65 parts of epoxy resin modified silicone resin, 18 parts of xylene, 12 parts of propylene glycol, 6 parts of zinc naphthenate, 4 parts of tri-n-butyl tin chloride, petroleum 5 parts of barium sulfonate, 9 parts of kerosene, 9 parts of lauroyl diethanolamine, 7 parts of p-methylaniline, 7 parts of zinc powder, 5 parts of silicon nitride, 7 parts of chromium carbide, 8 parts of aluminized glass beads, carbon dioxide 7 parts of silicon, 5 parts of aluminum oxide, 4 parts of calcium sulfate whisker powder, 8 parts of polytetrafluoroethylene, 8 parts of aloe juice, 13 parts of talcum powder, 12 parts of titanium yellow, 4 parts of cardanol modified amine curing agent , 1 part of leveling agent, 1 part of defoamer;

[0032] (2) Add epoxy resin modified silicone resin, xylene, and propylene glycol into the reaction kettle, and stir for 3-5 minutes at a speed of 550-650 rpm;

[0033] (3) Zinc naphthenate,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com