High-flow-state anti-segregation self-compacting concrete

A self-compacting concrete and anti-segregation technology, applied in the field of building materials, can solve the problems of parameter value and meaning difference, and achieve the effect of improving fluidity, ensuring cohesion, and reducing water-binder ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

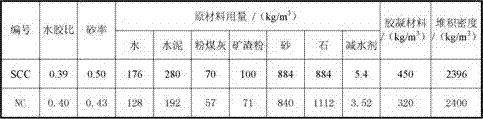

[0038] The following is a specific C30 concrete mix ratio design (numbered as SCC mix ratio) configured in the construction of the cast-in-place concrete acoustic wind tunnel project for the concrete of the present invention. For the convenience of comparing the difference between ordinary concrete and self-compacting concrete, the following The mix ratio corresponding to ordinary concrete is also listed in the table (the mix ratio numbered as NC).

[0039] Table 2

[0040]

[0041] cement:

[0042] The cement used in SCC and NC concrete raw materials is P•O 42.5R early-strength ordinary Portland cement produced by Beichuan Zhonglian Cement Co., Ltd., which contains 6% gypsum, 6% limestone powder, 10% slag, and 0.06% grinding aid. %, the specific surface area is 373-388㎡ / kg, the 3d compressive strength is 33.9MPa, and the 28d compressive strength is 52.7MPa.

[0043] Fine aggregate:

[0044] Manufactured sand: It is the sand made of rocks after soil removal, mechanical c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com