Inorganic composite material, preparation method and application thereof in removing heavy metal ions for sewage treatment

An inorganic composite material, brucite technology, applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of large land occupation of treatment facilities, heavy burden on enterprises, and low removal efficiency and other issues, to achieve the effect of reducing processing costs, reducing floor space, and increasing surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

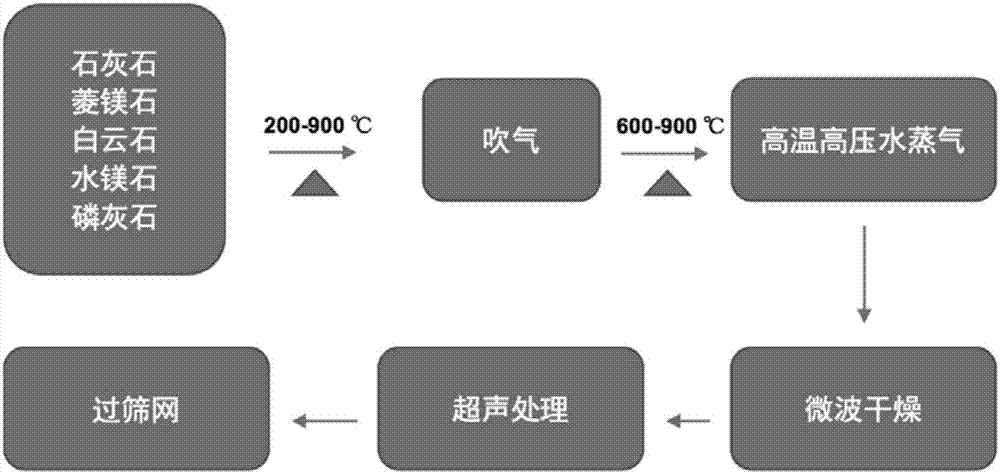

[0028] Example 1: Synthesis of materials

[0029] (1) Mix 100 grams of limestone, 30 grams of magnesite, 30 grams of dolomite, 30 grams of brucite, and 2 grams of apatite, and react in a sealed manner at 450°C for 6 hours;

[0030] (2) Mix the reaction products of step (1) uniformly, fill with air at 200°C, and continue to blow air for 30 minutes;

[0031] (3) The product obtained in step (2) is calcined at a high temperature, the temperature is 750°C, and the calcining time is 30 minutes;

[0032] (4) Fill the calcined product of step (3) with water vapor, and perform hydration at high temperature and high pressure (3 atmospheres, 120°C);

[0033] (5) Subjecting the hydrated product of step (4) to microwave drying treatment;

[0034] (6) The product after the microwave drying treatment is ultrasonically crushed and passed through a 200-screen mesh to obtain the final required material.

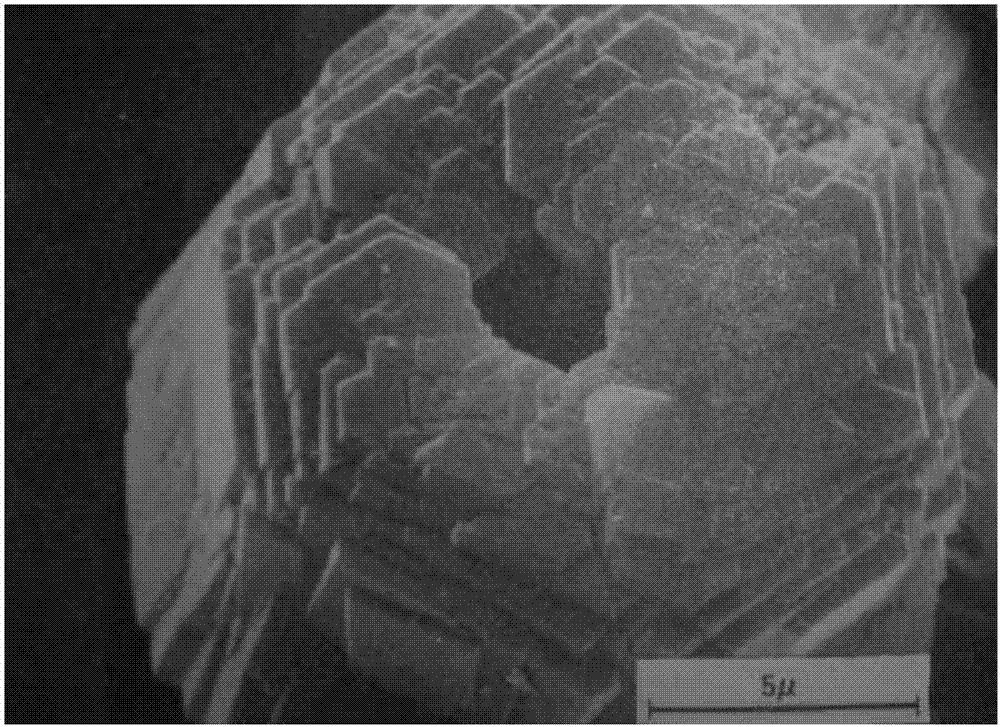

[0035] The particle size of the material obtained in the above synthesis step is 10-30 microns, and t...

Embodiment 2

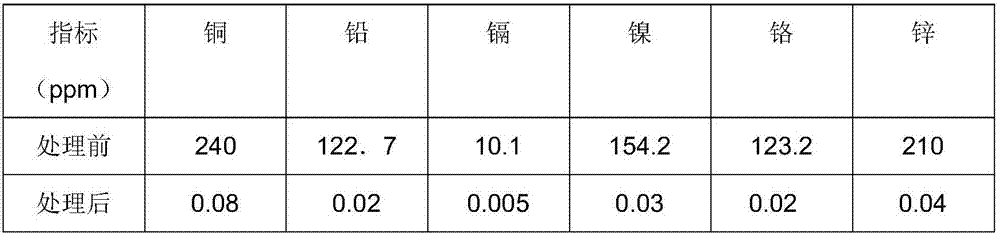

[0036] Example 2: Direct treatment of typical heavy metal sewage

[0037] 1g of the material was added to 100ml of experimental self-made sewage water samples (prepared with heavy metal ions in pure water) containing different heavy metal pollutants, and stirred at room temperature at a uniform speed at 100 revolutions per minute. After 6 hours of stirring and reaction, the main pollutant indicators of the sewage were tested. The main indicators before and after treatment are shown in the following table:

[0038]

[0039] It can be seen from the table that the various indicators of the treated sewage have decreased significantly. With reference to the relevant national environmental protection regulations, the above indicators of the treated sewage meet the requirements of the "People's Republic of China Integrated Wastewater Discharge Standard" (GB8978-1996).

Embodiment 3

[0040] Example 3: Used as a filling material with equipment

[0041] Add 100g of the material into a column with a diameter of 10cm and a length of 15cm. The liquid conveying equipment will circulate 500ml of sewage containing different metals at a rate of 1000 cubic centimeters per hour. The treatment time is 6 hours. The pollutant indicators are tested. The main indicators before and after treatment are shown in the following table:

[0042]

[0043] It can be seen from the table that the various indicators of the treated wastewater have decreased significantly. With reference to the relevant national environmental protection regulations, the above indicators of the treated wastewater all meet the national special limit standards.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com